NdFeB bonded compression magnets also have some unique characteristics and considerations that should be taken into account when using them:

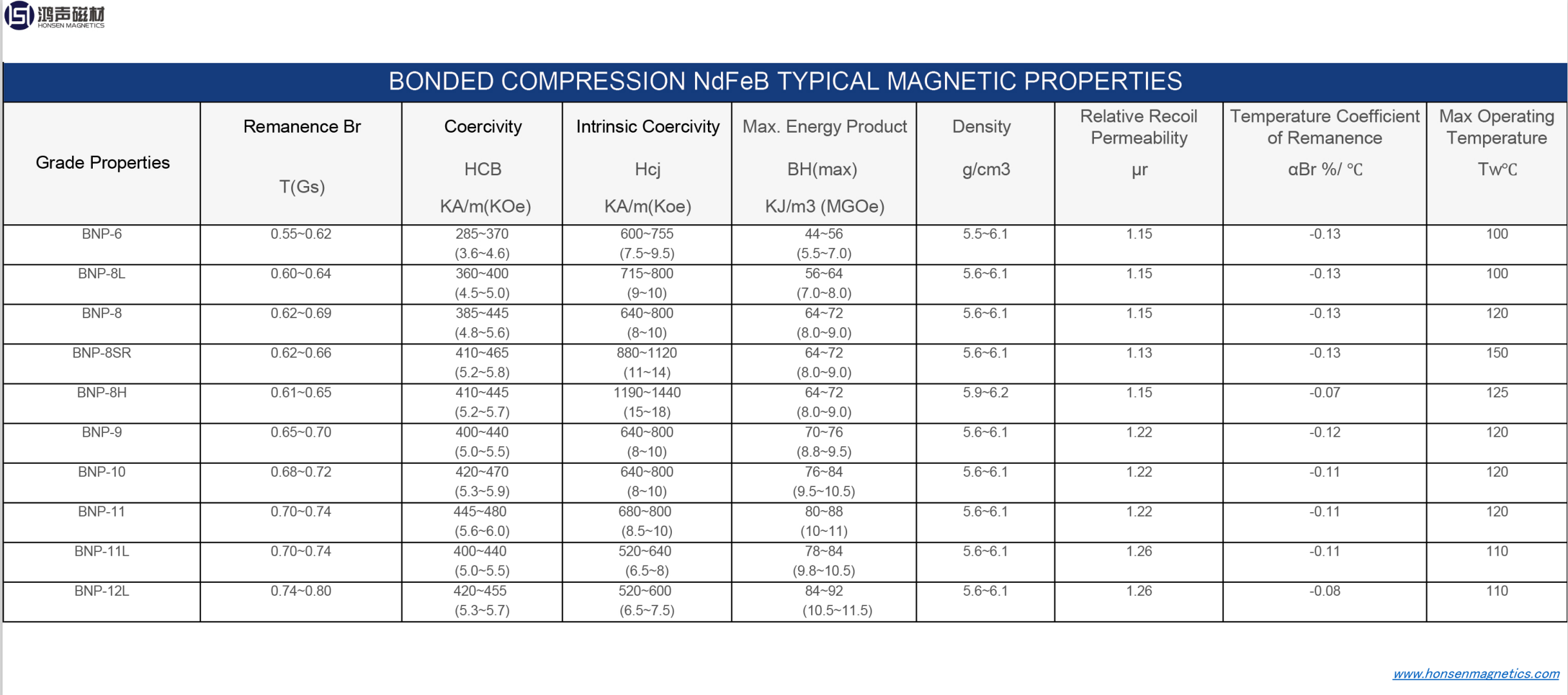

- They have lower magnetic properties than traditional NdFeB magnets, which means they may not be suitable for applications that require extremely strong magnetic fields.

- They are typically more brittle than other types of magnets, which can make them more prone to cracking or breaking during handling or use.

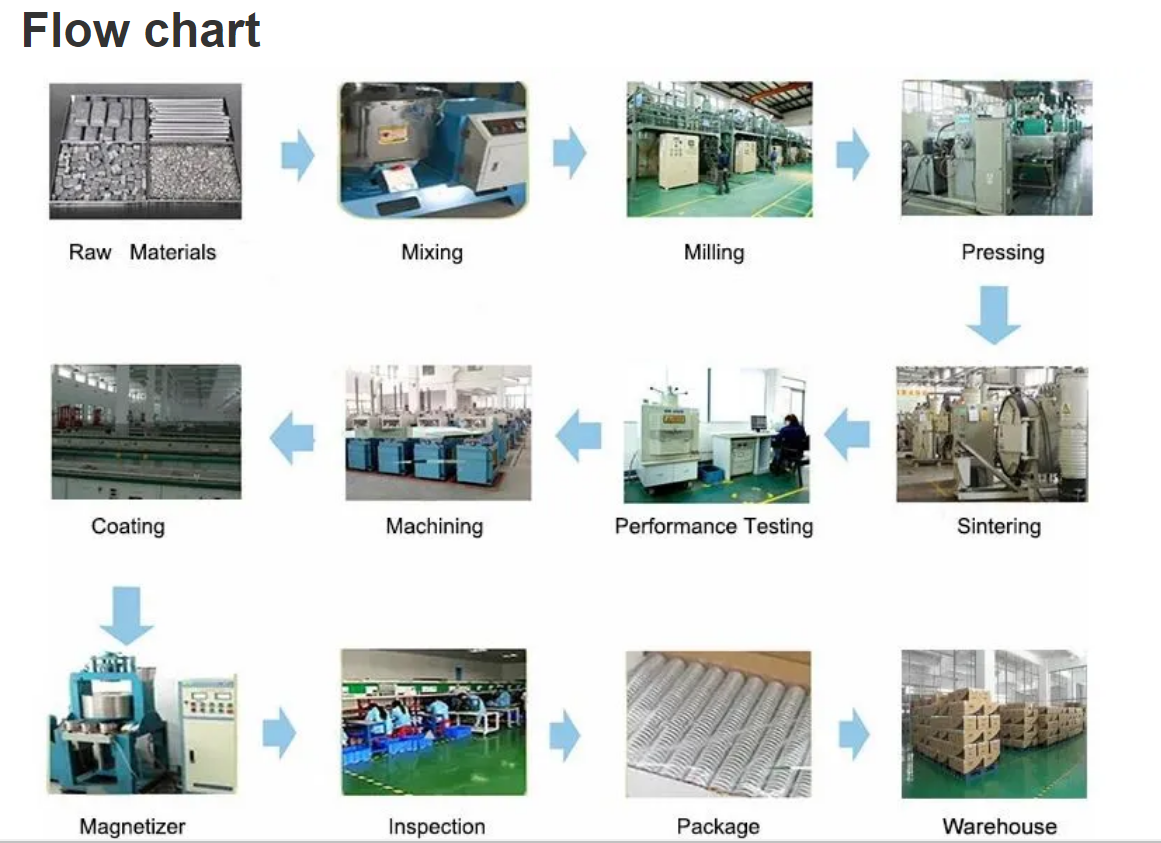

- They can be difficult to machine or drill, due to their high hardness and brittleness.

- They can be sensitive to temperature changes, which can cause changes in their magnetic properties. In some cases, this may result in a loss of magnetic strength.

- They can be coated with a variety of materials to protect against corrosion, but the coating may affect their magnetic properties.

It is important to work with a reputable manufacturer and carefully consider the specific requirements of the application when selecting NdFeB bonded compression magnets. Proper handling, machining, and protection from temperature and corrosion can help to maximize their performance and lifespan.