Samarium Cobalt (SmCo) Magnets

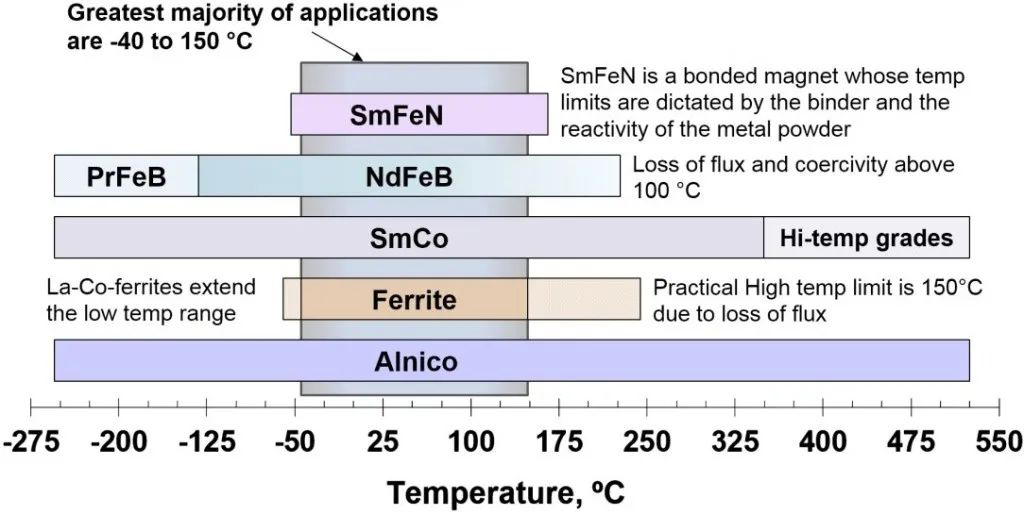

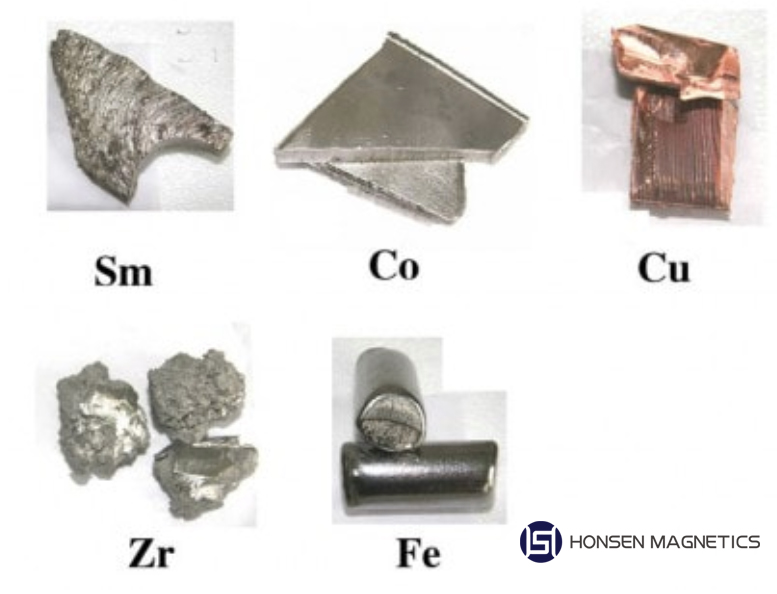

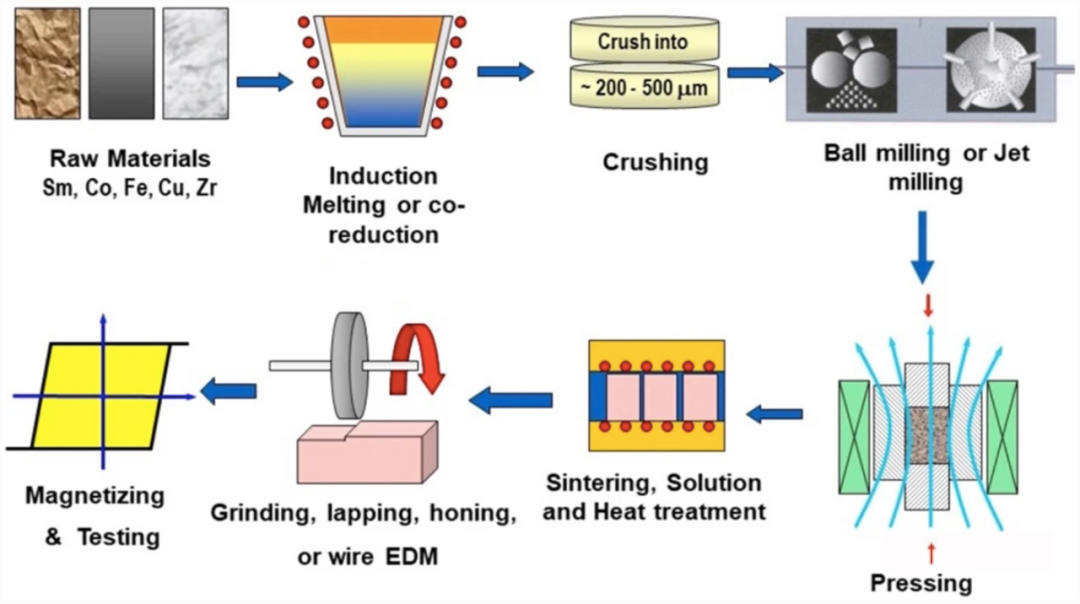

Samarium Cobalt Magnets (SmCo Magnets) are a type of high-performance permanent magnet material. They are manufactured using metallic samarium, cobalt, and other rare metals, making them the most costly magnetic material to produce. The manufacturing process involves melting, milling, pressing, and sintering, resulting in different properties and grades of magnets. One notable advantage of SmCo magnets is their high resistance to corrosion, as well as their ability to withstand high temperatures, reaching up to 350 °C, and sometimes even 500 °C. This temperature resistance sets them apart from other permanent magnets that have a lower tolerance to extreme temperatures, giving SmCo magnets a significant edge.

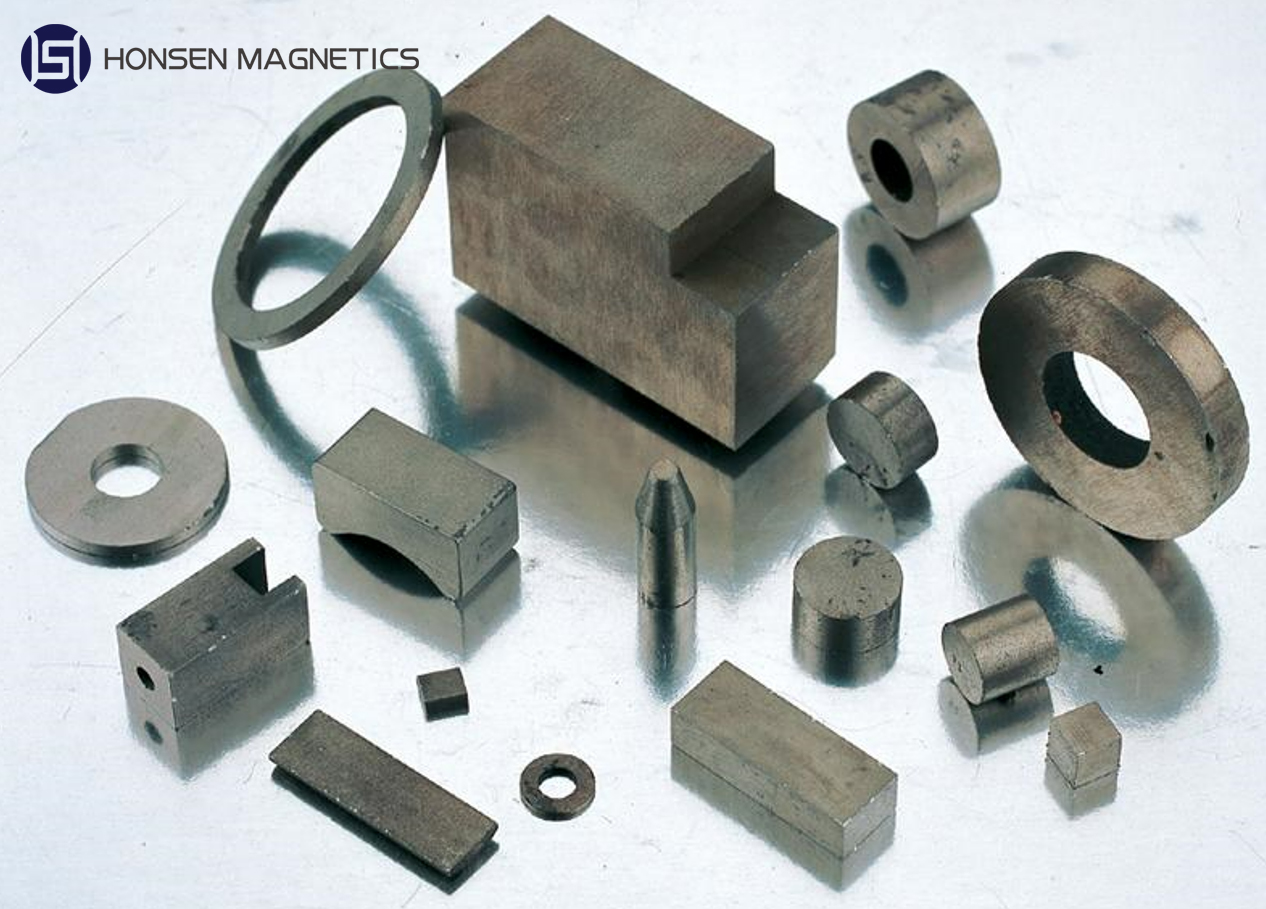

As per customer specifications, roughcasts of SmCo Magnets will undergo mechanical processing to attain the desired shapes and sizes. Unless instructed otherwise by the customer, the final products will be magnetized. Magnetic materials, such as SmCo Magnets, possess inherent magnetism and exhibit various magnetic effects. They are capable of generating magnetic fields for applications such as motors, magnetic machinery, sensors, and microwave devices, among others. By acting as a medium for transferring and converting magnetic energy into mechanical energy and electrical energy, magnetic materials facilitate control and achieve desired effects.

SmCo Magnets are equivalent in strength to Neodymium Magnets but have higher temperature resistance and coercivity. SmCo Magnes are the preferred choice for the most demanding motor applications due to their strong resistance to demagnetization impacts and excellent thermal stability. Like Neodymium Magnets, SmCo Magnes also require coatings to prevent corrosion. However, its corrosion resistance is significantly better than that of NdFeB. In acidic environments, SmCo Magnes should still be coated. Its corrosion resistance also provides assurance for those considering using magnets in medical applications.

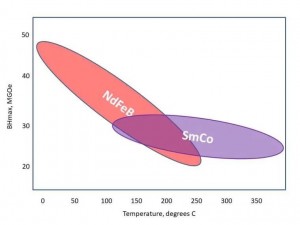

NdFeB Magnet performs well at lower temperatures, while SmCo Magnet performs well at higher temperatures. Neodymium Iron Boron Magnets are the strongest permanent magnets at room temperature and up to about 230 degrees Celsius, measured by their residual magnetism Br. But their strength rapidly decreases with increasing temperature. When the working temperature approaches 230 degrees Celsius, the performance of samarium cobalt magnets begins to outperform that of NdFeB.

SmCo Magnet is the second strongest magnetic material with excellent anti-demagnetization ability, widely used in the aerospace industry or industrial fields where performance is a priority and cost is secondary. The SmCo Magnets developed in the 1970s are stronger than Ceramics Magnets (Ferrite Magnets) and Aluminum Nickel Cobalt Magnets (AlNiCo Magnets), but not as strong as Neodymium Magnets. Samarium Cobalt Magnets are mainly divided into two categories, divided by energy range. The energy product range of the first group Sm1Co5 (also known as 1-5) and the range of the second group Sm2Co17 (2-17).

Honsen Magnetics produces various forms of SmCo5 and Sm2Co17 magnets.

Manufacturing Process of SmCo Magnets

SmCo Magnets and Neodymium Magnets share a similar production process. They begin as powder metals, which are mixed and compacted under a strong magnetic field. The compacted materials are then sintered to create solid magnets. When it comes to machining, both materials necessitate the use of diamond tools, electric discharge machining, or abrasive grinding. These processes are essential for achieving the desired shape and dimensions of the magnets. The manufacturing process of SmCo (Samarium Cobalt) magnets involves several steps:

Powder process→ Pressing→ Sintering → Magnetic property test → cutting → finished products

SmCo Magnets are commonly processed under un-magnetized circumstances, with a diamond grind wheel and wet fine grinding, which is necessary. Because of low ignition temperature, SmCo Magnets must not be dry completely. Just a small spark or static electricity in production can easily trigger a fire, with extremely high temperature, which is hard to control.

Basic Features of SmCo Magnets

Demagnetization is particularly difficult for samarium-cobalt

SmCo magnets are temperature stable.

They are expensive and subject to price fluctuations (cobalt is market price sensitive).

Samarium-cobalt magnets have high corrosion and oxidation resistance, are rarely coated and may be employed

Samarium-cobalt magnets are fragile and easily cracked and chipped.

Samarium Cobalt Magnets that have been sintered display magnetic anisotropy, which limits the direction of magnetization to the axis of their magnetic orientation. This is accomplished by aligning the material's crystal structure as it is being manufactured.

SmCo Magnets VS Sintered NdFeB Magnets

The following are the main distinctions between sintered NdFeB magnets and SmCo magnets:

1. Magnetic force:

The magnetic force of a Permanent Neodymium Magnet is greater than that of a SmCo Magnet. Sintered NdFeB has a (BH)Max of up to 55MGOe, whereas SmCo material has a (BH)Max of 32MGOe. Compared to NdFeb material, SmCo material is better at resisting demagnetization.

2. High-temperature resistance

In terms of high-temperature resistance, NdFeB is not better than SmCo. NdFeB can withstand temperatures up to 230 °C whereas SmCo can withstand temperatures of up to 350 °C.

3. Corrosion resistance

NdFeB magnets struggle to withstand corrosion and oxidation. Typically, they need to be plated or even vacuum-packed to protect them. Zinc, nickel, epoxy, and other coating materials are frequently used. Magnets made of SmCo won't rust.

4. Shape, process, and assembling

Due to their fragility, NdFeb and SmCo cannot be produced using standard cutting processes. Diamond wheel and wire electrode cutting are the two main processing techniques. This limits the forms of these magnets that may be produced. Shapes that are too intricate cannot be used. SmCo material is more brittle and breakable relative to other materials. Therefore, when building and utilizing SmCo magnets, please exercise extreme caution.

5. Price

SmCo magnets were twice as expensive if not three times as expensive, as NdFeB magnets a few years ago. Due to the country's prohibitive policies in rare-earth mining, the price of NdFeB has significantly increased in recent years. In essence, regular NdFeB magnets are less expensive than samarium cobalt.

Applications of SmCo Magnets

Strongly resistant to corrosion and oxidation, SmCo Magnets find extensive use in the fields of aviation, aerospace, national defense, and the military, as well as in the production of microwave components, therapy equipment, instruments, and apparatus, as well as various types of magnetic sensors, processors, motors, and lifting magnets. Similar industrial uses for NdFeB include switches, loudspeakers, electric motors, instruments, and sensors.

WHY CHOOSE US

For over ten years, Honsen Magnetics has excelled in the manufacturing and trading of Permanent Magnets and Magnetic Assemblies. Our production lines cover key processes such as machining, assembly, welding, and injection molding, allowing us to offer a comprehensive solution to our customers. With our extensive capabilities, we are able to produce high-quality products that meet the highest standards.

1. We are capable of manufacturing a wide range of Samarium Cobalt products in various shapes and possessing different properties.

2. Our manufacturing capabilities extend to producing SmCo Magnets with big size, all magnetized to their full potential.

3. We possess the necessary expertise and resources to conduct mass production of high-grade YXG-33H magnets, which boast a (BH)max of 30-33MGOe.

4. We have the capacity to supply large quantities of SmCo Magnets in stability, and performance, and possess a high coercivity of HK (HK≥18KOe).

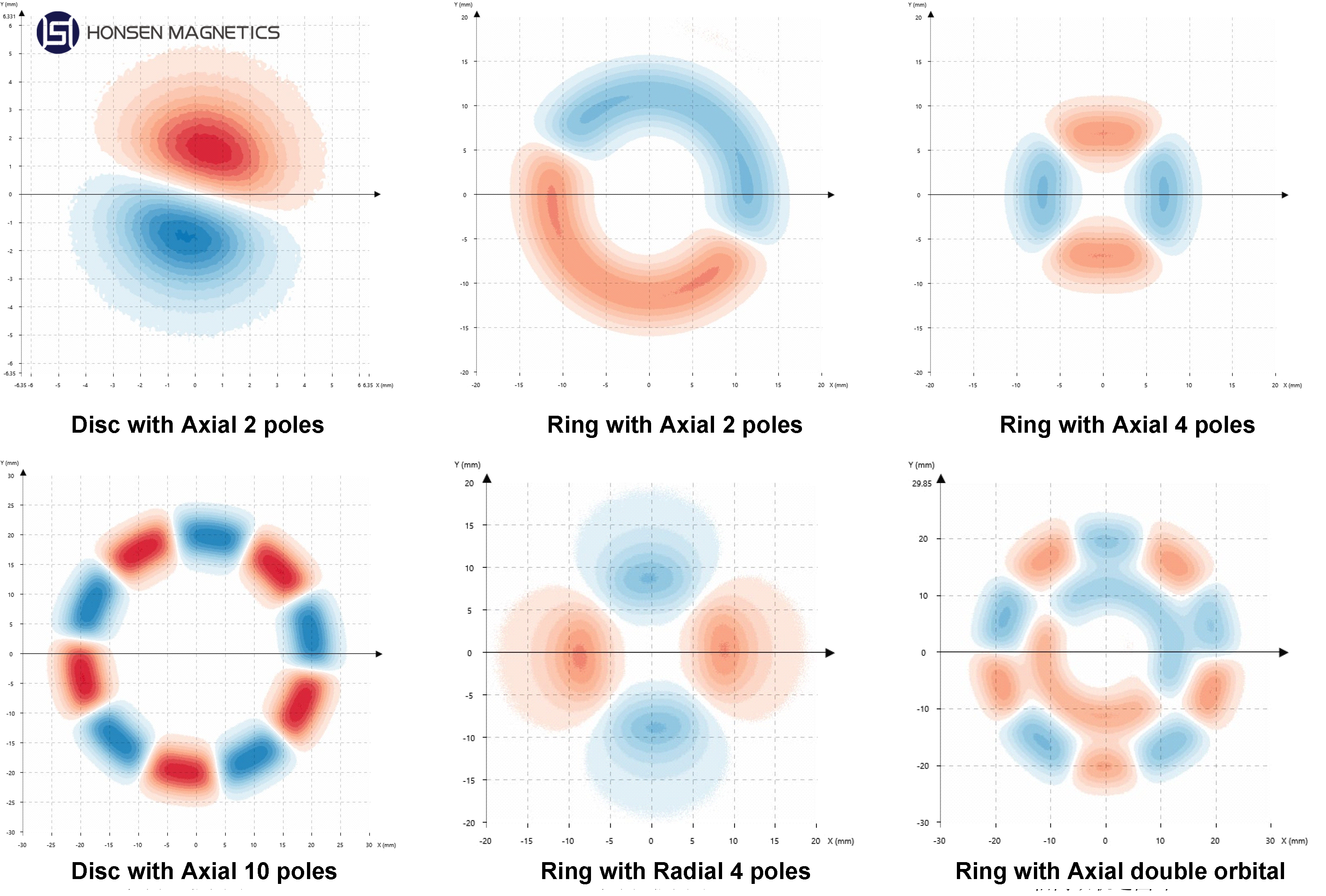

5. We can engineer magnets with multi-poles, but it is important to note that the magnetization thickness should generally not exceed 6mm.

6. We are able to provide magnets with a magnetic deviation of less than 1°, ensuring exceptional precision in magnetic field alignment.

7. We have the capability to customize YXG-35 grade SmCo products with an ultra-high magnetic energy product, offering a Br range of 11.6-12kGs and a (BH)max range of 32-35MGOe. This magnetic energy product is currently the highest in the samarium cobalt industry.

8. We offer customizable SmCo Magnets with an ultra-low temperature coefficient (LTC) such as the YXG-18 series. These magnets exhibit excellent temperature stability, with a temperature coefficient of Br at RT-100℃ of -0.001%/℃.

9. We also provide high-temperature-resistant HT500 SmCo Magnets that can be tailored to your specifications. These magnets can withstand extreme temperatures, with a maximum working temperature of 500℃.

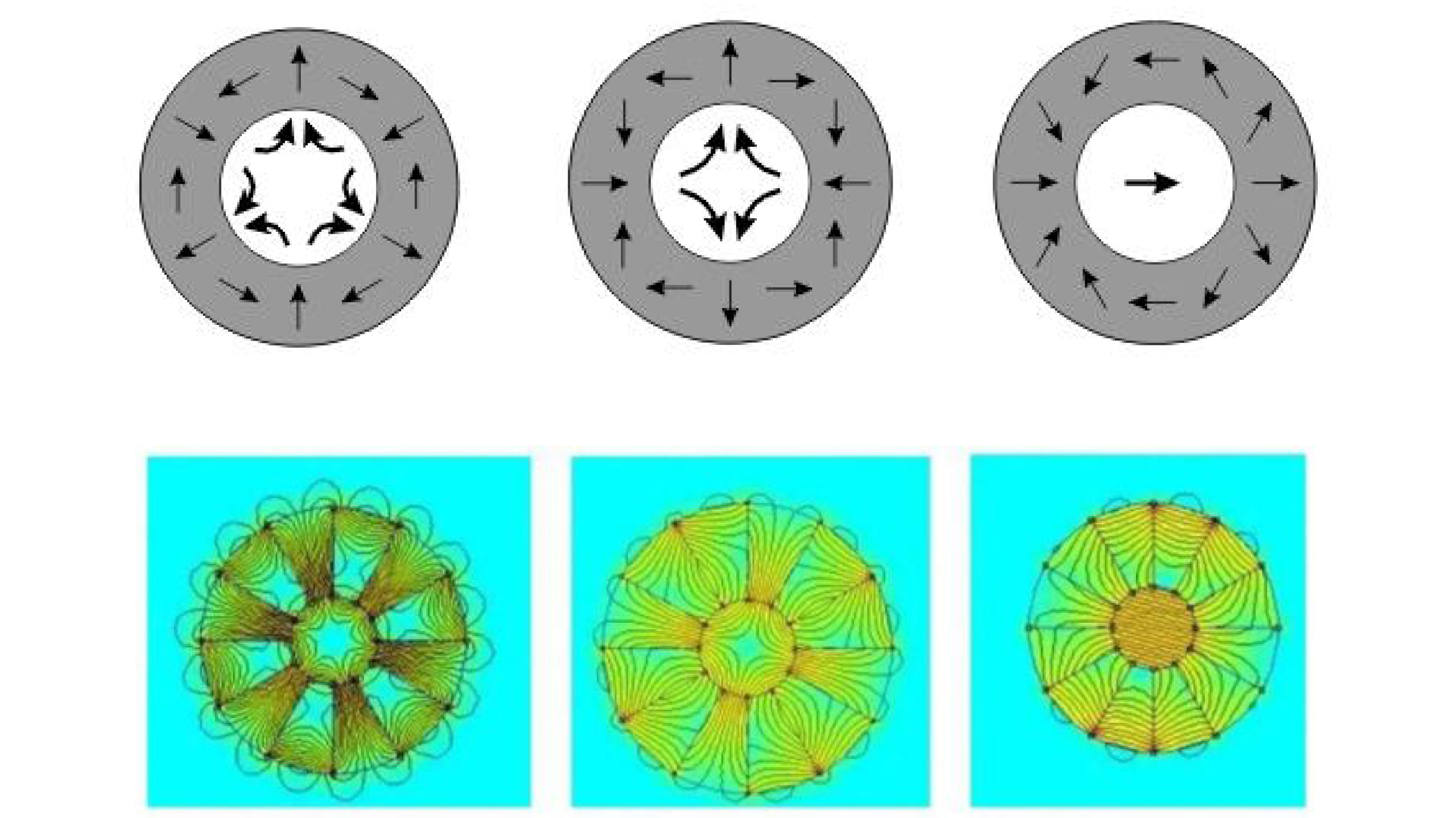

10. We have the capability to produce SmCo Magnets in various complex shapes and offer multi-angle magnetization options, including Halbach Arrays.

Multipole Magnetization

Angle Deviation

Halbach Array

PRODUCTION FACILITIES

We are committed to providing our customers with proactive support and innovative, competitive products that strengthen our foothold in the market. Motivated by revolutionary breakthroughs in permanent magnets and components, we are steadfast in pursuing growth and exploring new markets through technological innovation. Under the direction of a chief engineer, our experienced R&D department leverages in-house expertise, nurtures client relationships, and keenly anticipates market trends. Autonomous teams diligently oversee global undertakings, ensuring the continued advancement of research projects.

QUALITY & SAFETY

Quality management is a fundamental aspect of our corporate identity. We regard quality as the heartbeat and compass of an enterprise. Our commitment goes beyond the surface as we integrate a comprehensive quality management system into our operations. Through this approach, we guarantee that our products consistently meet and exceed our customers' requirements, reflecting our dedication to unparalleled excellence.

OUR PACKAGING

We understand the importance of packaging for magnetic material shipments, especially by air and sea. The unique properties of magnetic materials require special attention and precautions to ensure their safe delivery to customers. To meet these requirements, we have developed a rigorous packaging process tailored specifically for magnetic products. Our packaging materials are carefully selected to provide optimum protection against external elements such as shock, moisture, and magnetic field disturbances. We use a combination of durable cardboard boxes, foam padding, and anti-static materials to protect the integrity of magnetic products during shipping. Additionally, we employ strict quality control measures to ensure that each packaged product meets our high standards.

By taking extra precautions in the packaging of magnetic materials, we aim to minimize the risk of damage, ensure the longevity of our products, and ultimately increase customer satisfaction. We believe that proper packaging is an important part of our commitment to safely and efficiently deliver high-quality magnetic products to our customers, regardless of the mode of transportation.