The use of magnetic fixing solutions in the production of precast concrete components can not only avoid damaging the rigid platform, prolong the service life of the mold and reduce the investment of the mold, which plays an important role in reducing the cost of prefabricated components, but also improve the product quality.

Honsen Magnetics provides comprehensive magnetic fixing solutions for precast concrete formwork, including shuttering magnets and adapters, magnetic chamfer and precast concrete embedded parts magnetic fixtures and other precast concrete accessories. With the development of construction industrialization, magnetic fixing products have been widely recognized and applied in the production of precast concrete formwork. So far, our customers are all over Europe, America, the Middle East, Australia, Southeast Asia and other countries and regions, and have accumulated a lot of production and application experience.

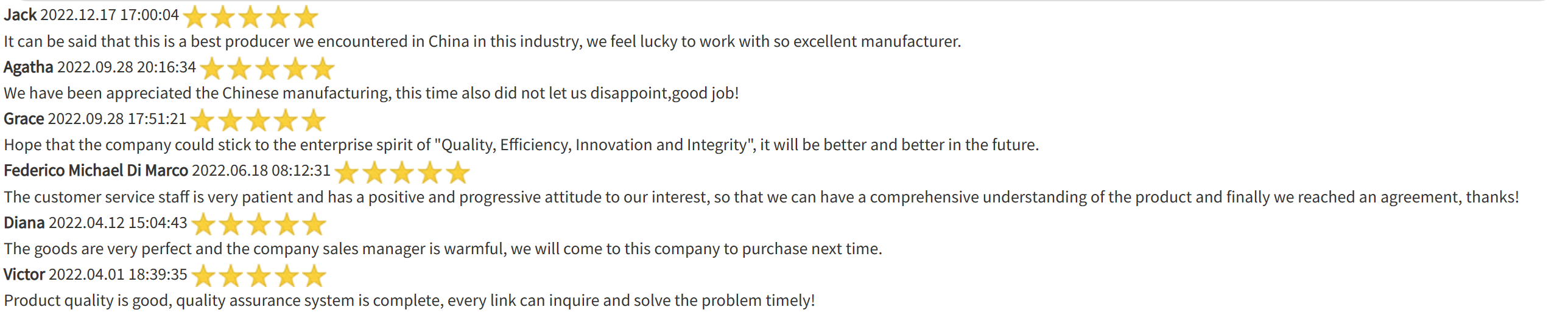

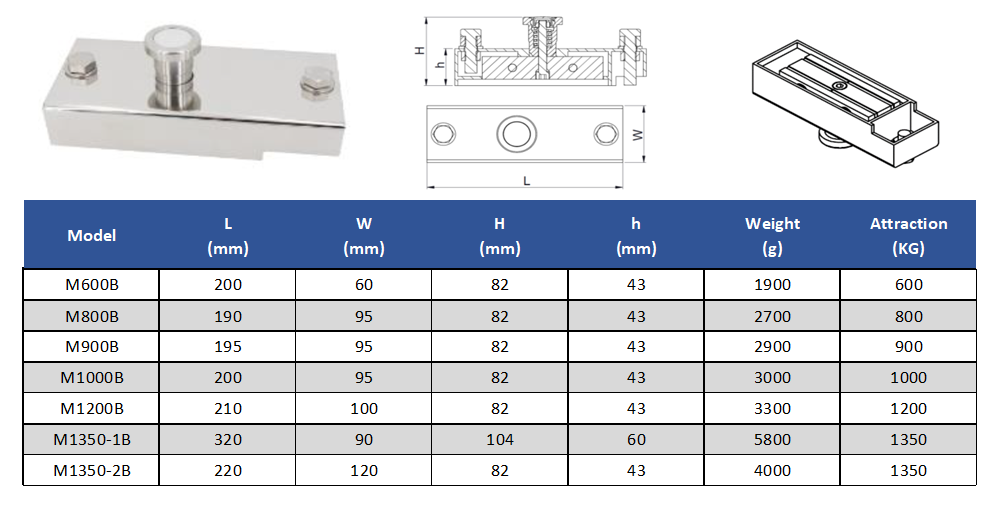

Our precast concrete magnetic box has reliable quality and mature technology. We can design and produce shuttering magnets with different suction and sizes according to the needs of customers. At the same time, we can design the corresponding shuttering system according to customers' different template specifications, sizes and use environment. Our advantages are also reflected in timely delivery and considerate service.

We have designed a convenient switch system and equipped with a switch crowbar (Shuttering Magnet Released Lever / Precast Concrete Magnets Lifting Lever). When the switch is closed, the magnetic tightness is good, and it is very safe to use.

Our shuttering magnet uses permanent magnets, in principle, the magnetic force is permanently within the working temperature range. We also fully takes into account the harsh environment of the construction site, and has a unique design in terms of rust prevention and sealing performance.

The template magnet consists of a switchable NdFeB template magnet unit, a housing containing the magnet block, and fixing screws. Through the combination of neodymium magnets and steel plates, a powerful magnetic circuit is formed to generate strong attraction. This force acts to hold the wood or steel formwork in place. The control buttons are located on top of the precast concrete magnets. When the button is pressed, the magnet engages its magnetic circuit, holding the template firmly to the steel plate. Instead, the deactivation button facilitates easy repositioning of the magnet. There are two universally threaded holes on the top of the template magnet, designed to accommodate different adapters. Our products can be customized according to your specific requirements, thus providing a diverse use experience.

First of all, according to the production of different components, choose the magnetic box with appropriate suction for different templates, if the suction is insufficient, the template will not be fixed firmly and affect the quality of components, it is not worth the loss.

Secondly, the service life of the product, that is the rust prevention, sealing performance, and whether the maintenance is convenient. The reason why the magnetic box may cause the attenuation of magnetic force in the process of use is that the combination between the magnetic surface and the platform is not tight enough. During construction, concrete or other garbage is accumulated on the magnetic surface, which affects the close fitting and causes the attenuation of suction. At the same time, if concrete or other garbage seeps into the magnetic box, or the switch is rusted, it will affect the use of the switch, and may also cause the magnetic surface to be unable to fit accurately with the platform, resulting in magnetic attenuation.

Finally, whether the product is safe and light to use, that is, when the switch is closed, whether the working magnetic force attenuates significantly, and whether the magnetic box can be moved easily.

- Simple installation and easy operation.

- Flexibility to select desired fixed positions, minimizing installation duration.

- Economical, with a swift payback period.

- Extended lifespan, making it reusable.

- Adhesive force spanning from 450 KGS to 3100 KGS.

- No need for welding; the magnet's magnetic force secures the template in place.

- Remarkable versatility, as a single prefabricated formwork magnet can suit diverse concrete formworks.

Why should you use Shuttering Magnets?

The precast concrete magnet is a magnetic tool used for fixing the concrete formwork. It is equipped with big block neodymium magnets into a steel house, there are two hexagonal bolts and a circular handle button on the top. The hexagonal bolt is used to fix the adapter, and the handle button is used for pushing. The traditional combination fixation adopts the screw nut fixation method. This method consumes a lot of time and labor in the process of assembling and removal and may need to drill holes in the platform, and even different component sizes require drilling at different positions, which destroys the platform, shortens the service life, and may even affect the quality of components. The shuttering magnet made of powerful rare earth permanent magnet materials solves these problems. The magnetic fixture is closely combined with the steel mold and platform through the action of magnetic force, which will not cause any damage to the platform mold. Moreover, our shuttering magnet has designed a switching system, which can easily and quickly disassemble the mold by turning

Honsen Magnetics has a history of more than ten years, focusing on the manufacture and sales of permanent magnets, magnetic components and magnet-related products. Our experienced team manages a comprehensive production line including machining, assembly, welding and injection molding. Due to their excellent quality and our dedication to customer-centric service, our products enjoy a high reputation in the global market, especially in Europe and America.

- More than 10 years experience in permanent magnetic products industry

- Over 5000m2 factory is equipped with 200 advanced Machines

- Have a complete production line from machining, assembling, welding, injection molding

- Have a strong R&D team can provide perfect OEM&ODM service

- Skilled workers & continuous improvement

- We only export qualified products to customers -

- Fast shipping & worldwide delivery

- Serve ONE-STOP-SOLUTION ensure efficient & cost-effective purchasing

- 24-hour online service with first-time response

We are committed to strengthening our market position by providing proactive support and innovative, competitive products to our customers. Through continuous technological innovation, our unique breakthroughs in permanent magnets and components drive growth and expansion into new markets. Led by our chief engineer, our experienced R&D department draws on in-house expertise, maintains customer relationships and anticipates market trends. Independent teams oversee global projects, ensuring that research continues to progress.

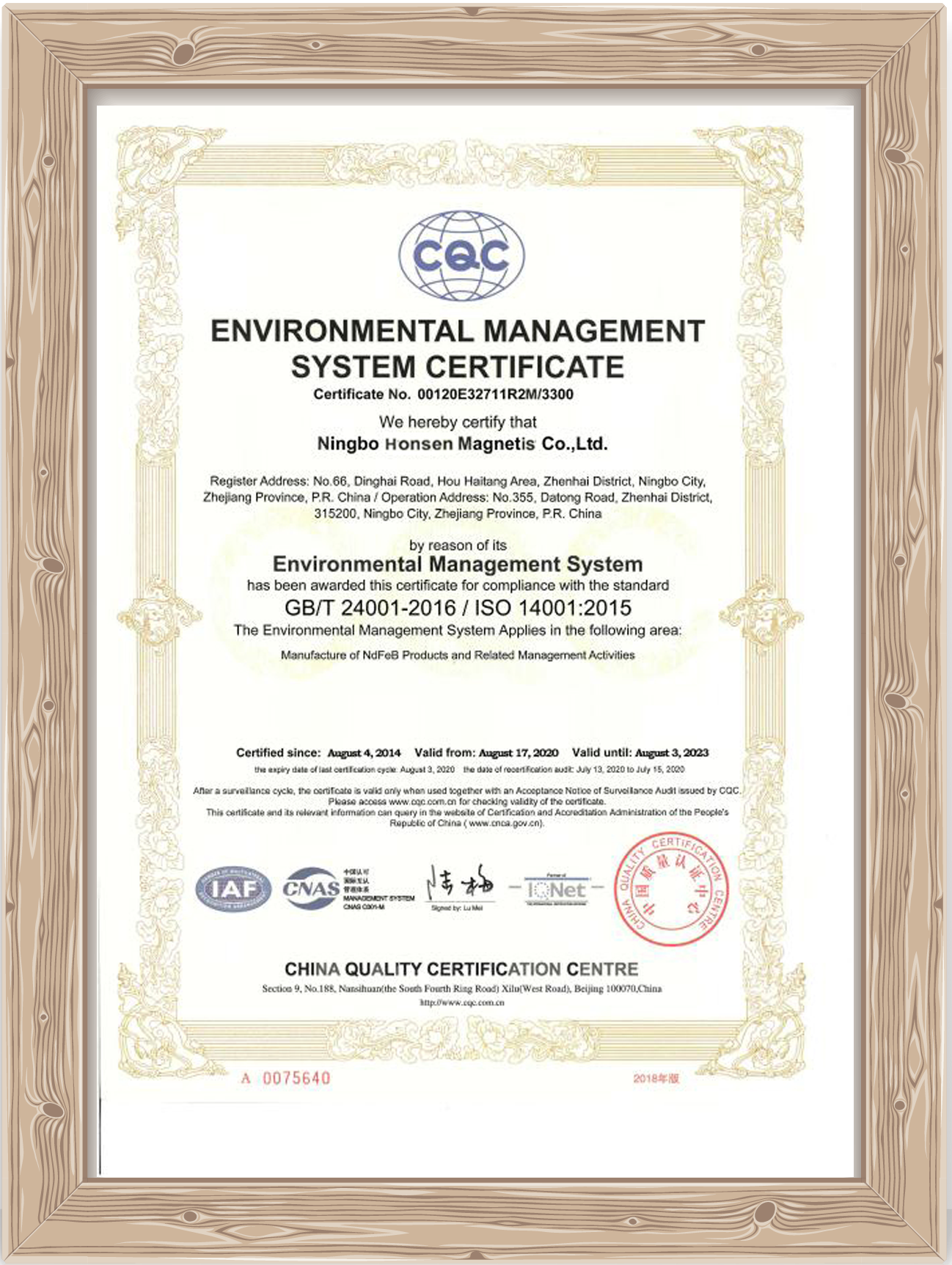

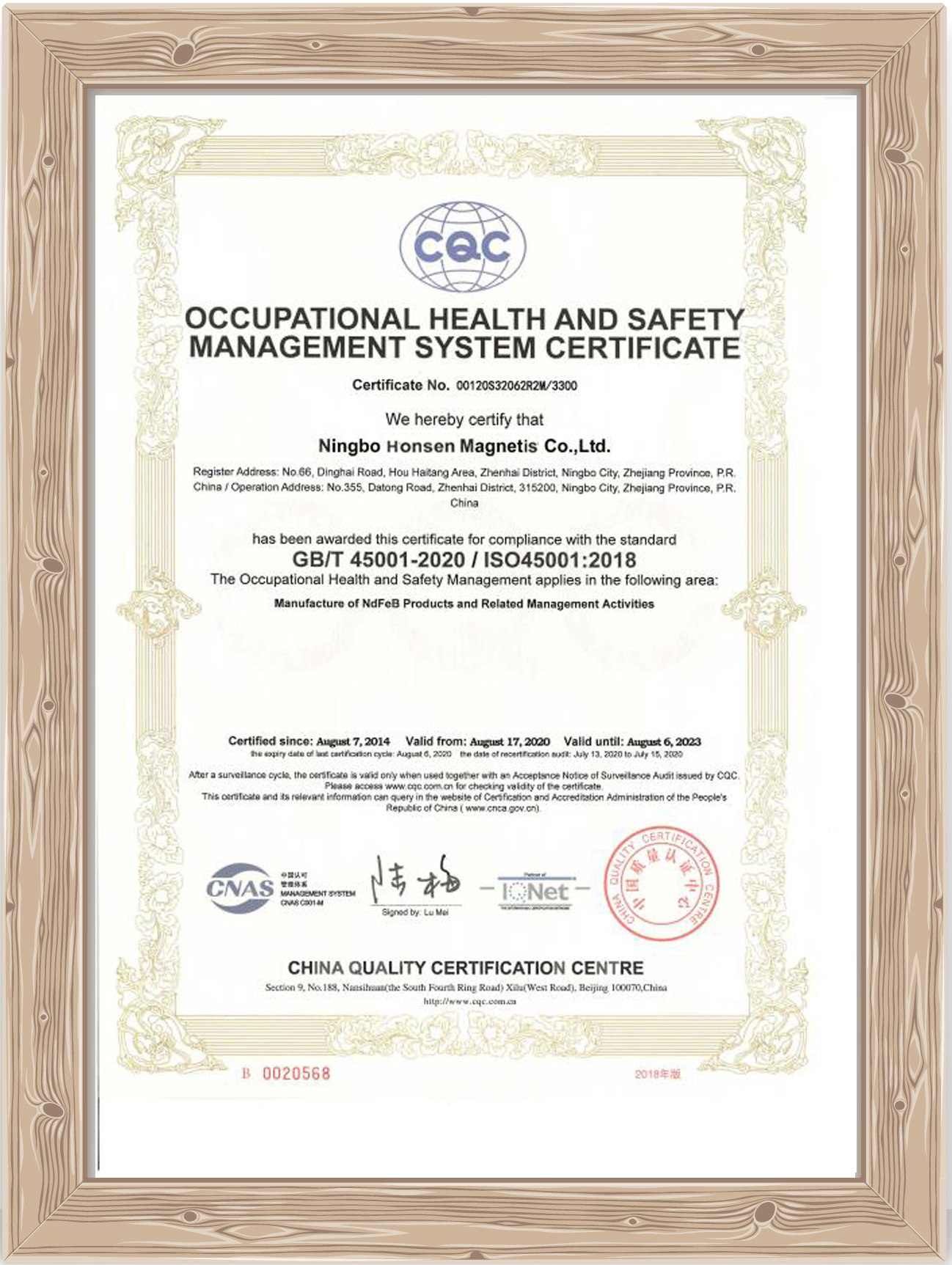

Quality management is the cornerstone of our corporate image. We believe that quality is not just a concept, but the vitality and navigation tool of our enterprise. Our commitment goes beyond form - our quality management system is seamlessly integrated into our operations. This ensures that our products consistently meet and exceed customer expectations, underpinning our commitment to raising quality standards.

Honsen Magnetics has mastered the art of balancing - striking the balance between delivering unparalleled customer satisfaction and an unwavering commitment to safety. This balance extends to our employees, where each individual journey is nurtured, recognizing that their growth is critical to the perpetual growth of our business.