Products

-

Neodymium Ring Magnets Manufacturer

Product Name: Permanent Neodymium Ring Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Neodymium ring magnet or customized

Magnetization Direction: Thickness, Length, Axially, Diametre, Radially, Multipolar

-

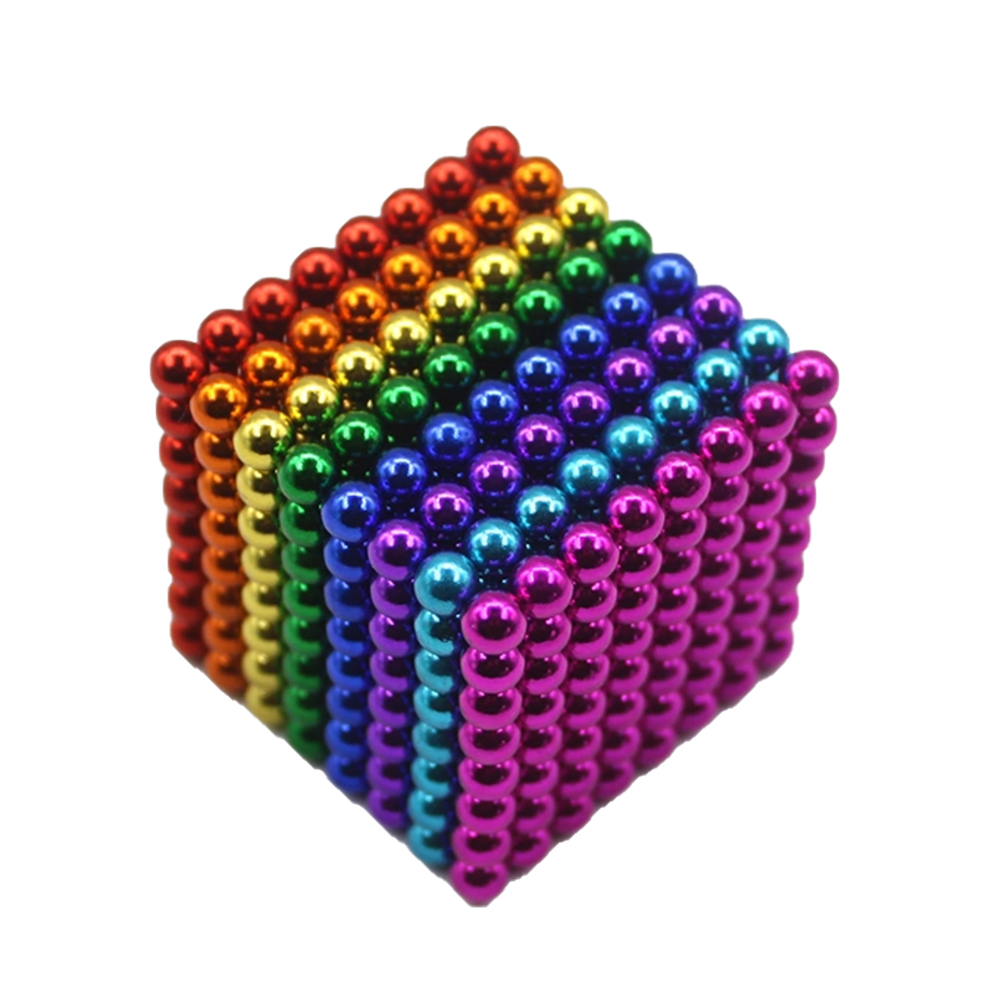

Strong NdFeB Sphere Magnets

Description: Neodymium Sphere Magnet/ Ball Magnet

Grade: N35-N52(M,H,SH,UH,EH,AH)

Shape: ball, sphere, 3mm, 5mm etc.

Coating: NiCuNi, Zn, AU, AG, Epoxy etc.

Packaging: Color Box, Tin Box, Plastic Box etc.

-

Strong Neo Magnets with 3M Adhesive

Grade: N35-N52(M,H,SH,UH,EH,AH)

Shape:Disc, Block etc.

Adhesive Type: 9448A, 200MP, 468MP, VHB, 300LSE etc

Coating: NiCuNi, Zn, AU, AG, Epoxy etc.

3M adhesive magnets is used more and more in our daily life. it is made up of neodymium magnet and high quality 3M self-adhesive tape.

-

Custom Neodymium Iron Boron Magnets

Product Name: NdFeB Customized Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: As per your request

Lead time: 7-15 days

-

Neodymium Channel Magnet Assemblies

Product Name: Channel Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Rectangular, Round base or customized

Application: Sign and Banner Holders – License Plate Mounts – Door Latches - Cable Supports -

Rubber Coated Magnets with Countersunk & Thread

Rubber coated magnet is to wrap a layer of rubber on the outer surface of the magnet, which is usually wrapped with sintered NdFeB magnets inside, magnetic conducting iron sheet and rubber shell outside. The durable rubber shell can ensure the hard, brittle and corrosive magnets to avoid damage and corrosion. It is suitable for indoor and outdoor magnetic fixation applications, such as for vehicle surfaces.

-

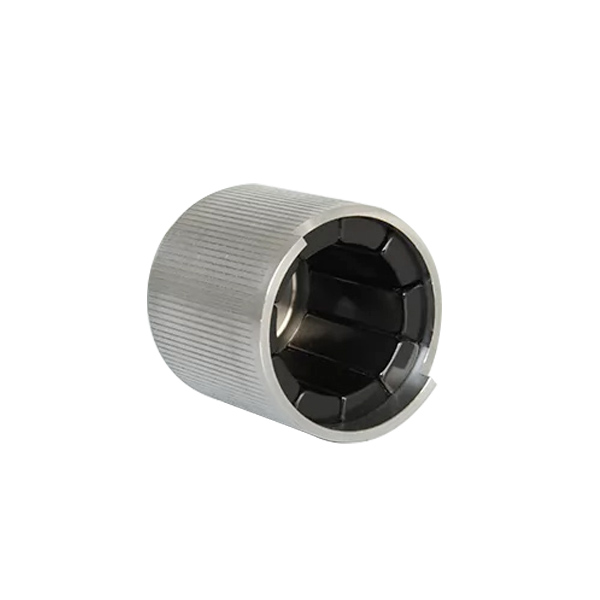

Magnetic Rotor Assemblies for High-Speed Electric Motors

Magnetic rotor, or permanent magnet rotor is the non stationary part of a motor. The rotor is the moving part in an electric motor, generator and more. Magnetic rotors are designed with multiple poles. Each pole alternates in polarity (north & south). Opposite poles rotate about a central point or axis (basically, a shaft is located in the middle). This is the principal design for rotors. Rare-earth permanent magnetic motor has a series of advantages, such as small size, light weight, high efficiency and good characteristics. Its applications are very extensive and extend all over fields of aviation, space, defense, equipment manufacturing, industrial and agricultural production and daily life.

-

Permanent Magnetic Couplings for Drive Pump & magnetic mixers

Magnetic couplings are non-contact couplings that use a magnetic field to transfer torque, force or movement from one rotating member to another. The transfer takes place through a non-magnetic containment barrier without any physical connection. The couplings are opposing pairs of discs or rotors embedded with magnets.

-

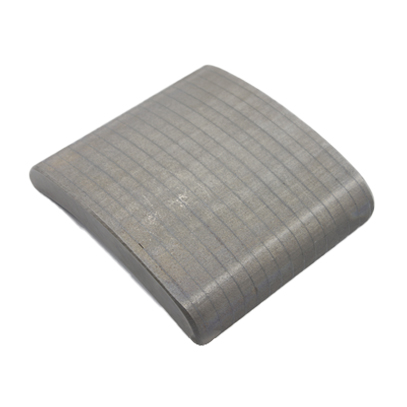

Laminated Permanent Magnets to reduce Eddy Current Loss

The purpose to cut a whole magnet into several pieces and apply the together is to reduce eddy loss. We call this kind magnets “Lamination”. Generally, the more pieces, the better the effect of eddy loss reduction. The lamination will not deteriorate the overall magnet performance, only the flux will slightly affected. Normally we control the glue gaps within a certain thickness using special method to control each gap has the same thickness.

-

N38H Neodymium Magnets for Linear Motors

Product Name: Linear Motor Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Neodymium block magnet or customized -

Halbach Array Magnetic System

Halbach array is a magnet structure, which is an approximate ideal structure in engineering. The goal is to generate the strongest magnetic field with the smallest number of magnets. In 1979, when Klaus Halbach, an American scholar, conducted electron acceleration experiments, he found this special permanent magnet structure, gradually improved this structure, and finally formed the so-called “Halbach” magnet.

-

Magnetic Motor Assemblies with Permanent Magnets

Permanent magnet motor generally can be classified into permanent magnet alternating current (PMAC) motor and permanent magnet direct current (PMDC) motor according to current form. PMDC motor and PMAC motor can be further divided to brush/brushless motor and asynchronous/synchronous motor, respectively. Permanent magnet excitation can significantly decrease power consumption and strengthen the running performance of the motor.