Cone Magnets are manufactured so the DoM is set auring the manufacturing process and cannot be changed. Available options during manufacturing for DOM:

From the base to the tip/top.Our Large Cone Magnets are defined with a base equal to or greater than 1.000” (25.40mm). The base, height, and top will determine the reach and profile of the magnetic field and performance of the cone magnets.Most common coating on magnets Actually 3 layers, nickel-copper-nickel Protection ofthe magnet from corrosion in ambient ain Not a protective coating from humidity, water, or salt water Light protection of the magnet from chipping A decorative finish Shiny metallic gray finish

Thickness: 12-25 microns

Cost: Low

Max working Temp:Approximately 2000C

Material:Ndfeb Magnet; Neodymium Magnet; Permanent Magnet

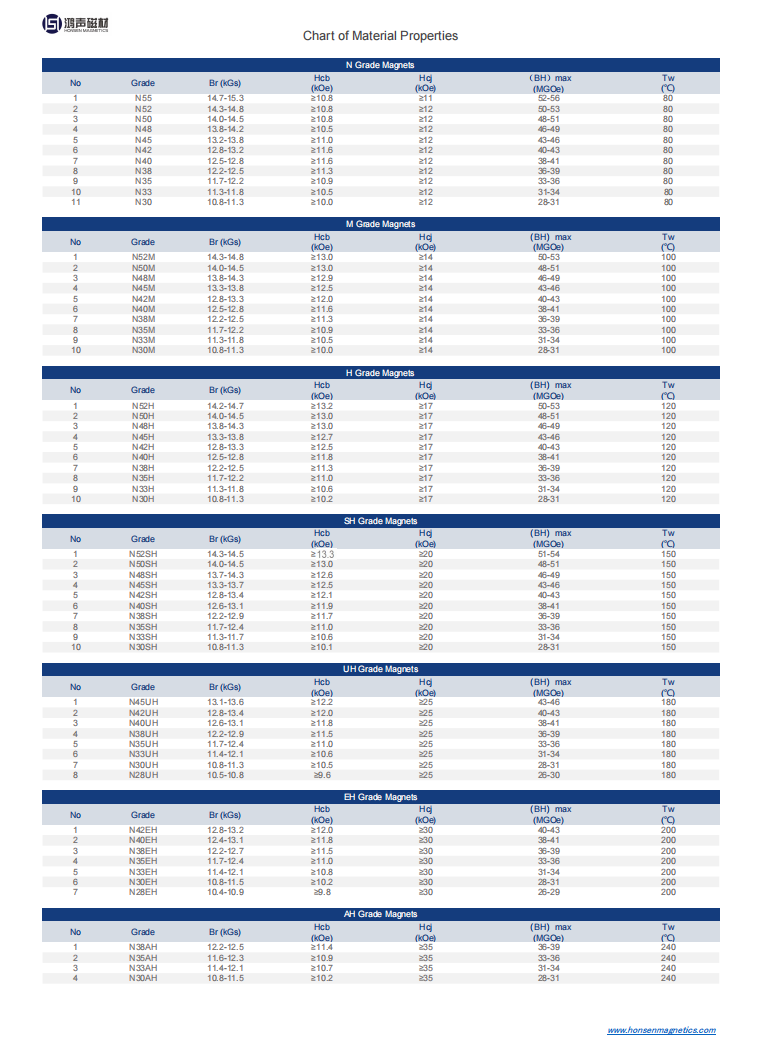

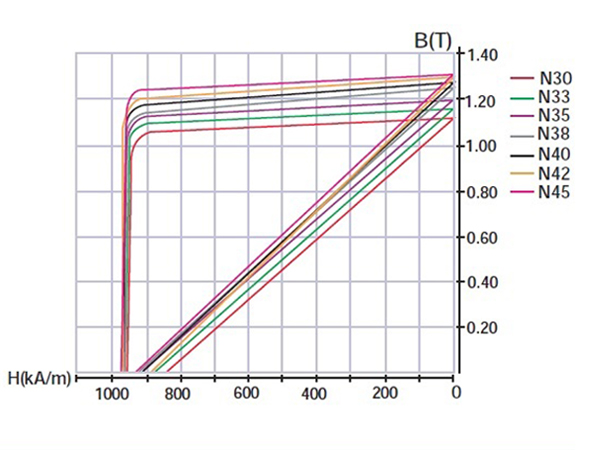

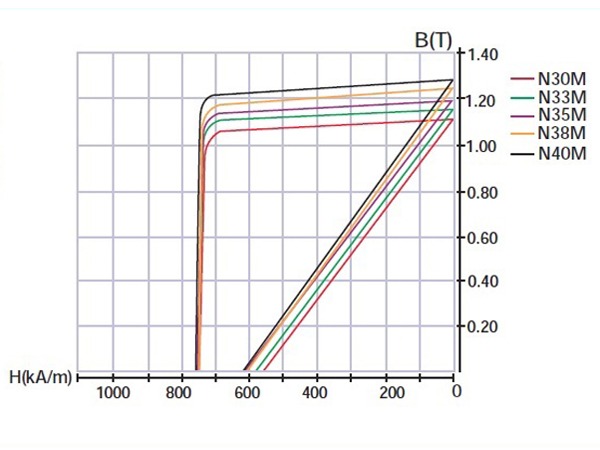

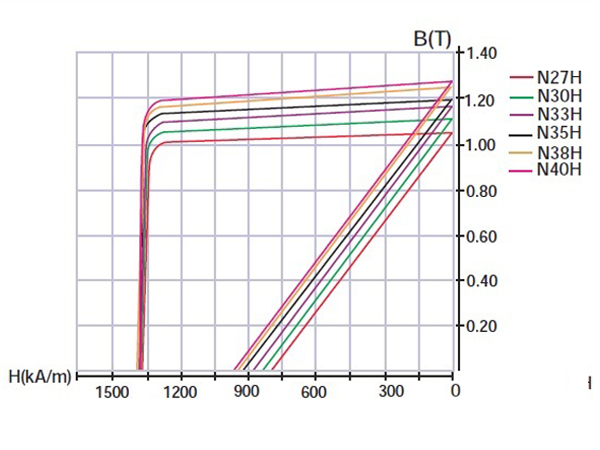

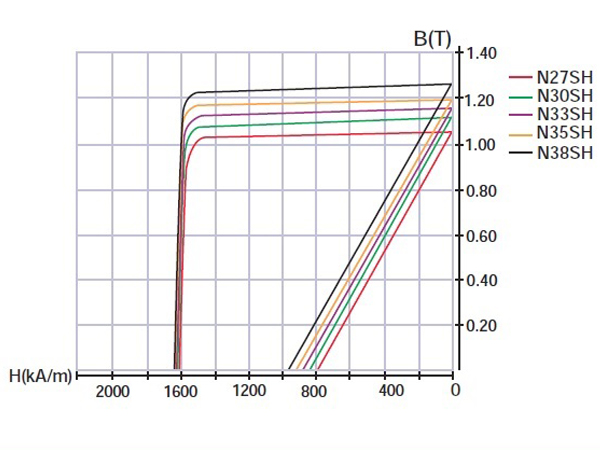

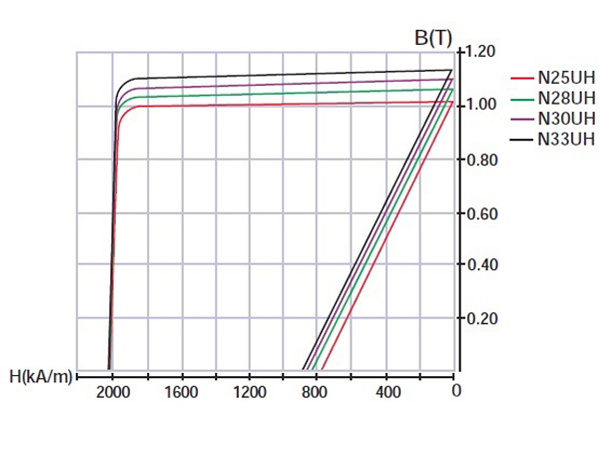

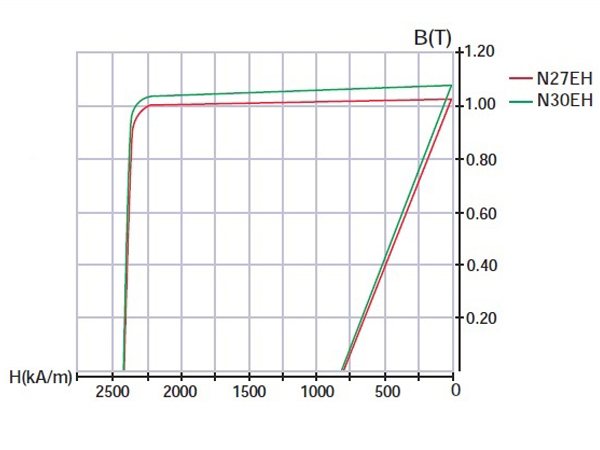

Grade:According to magnet application and working temperature

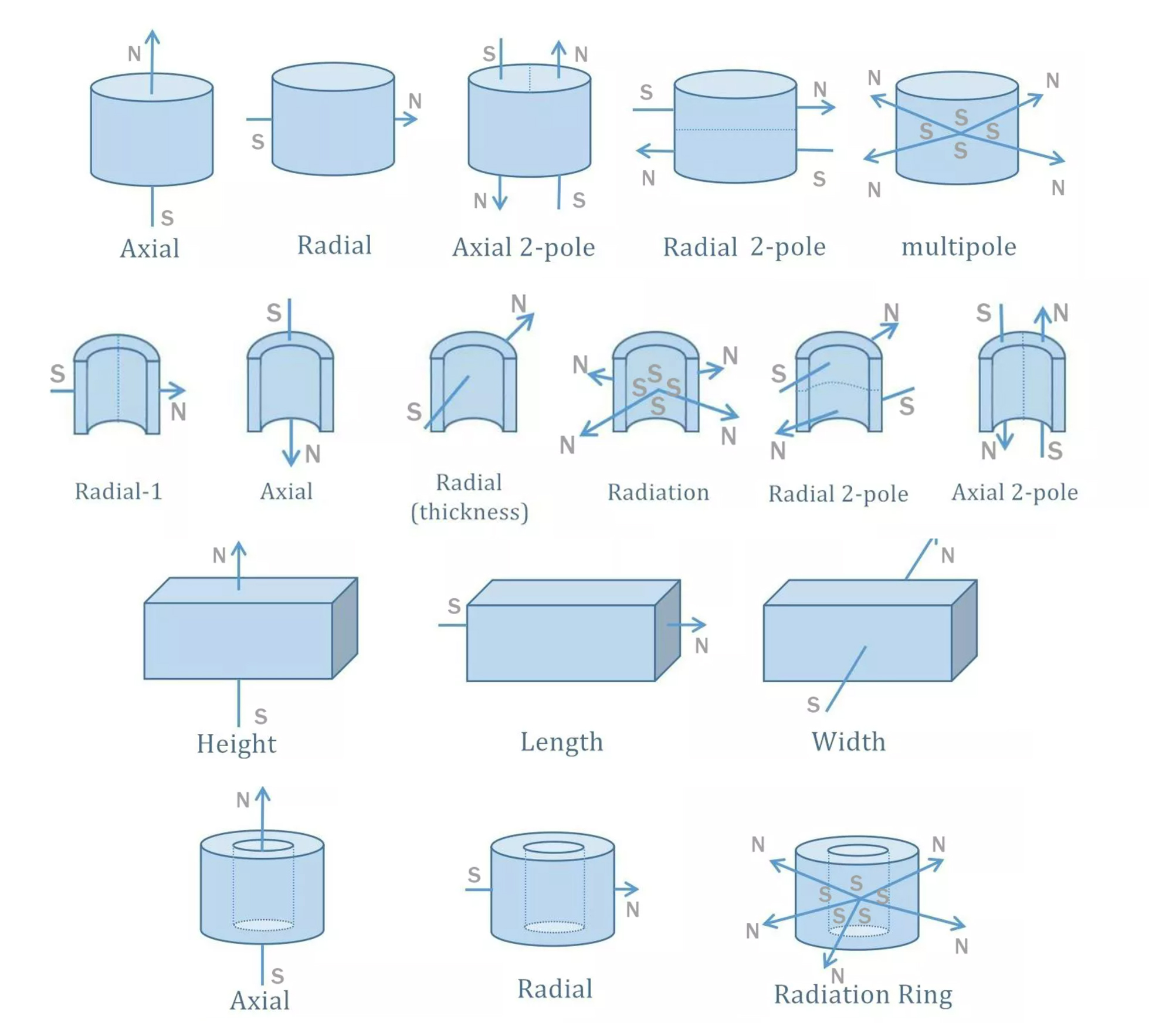

Shape:Block, Bar, Disc, Ring, Cylingder, Segment, and irregular shapes can be done with drawings.

Size:Customized sizes according to requirement

Coating:Nickel, Zinc, Black epoxy, Grey Epoxy, Gold, Rubber, eto

Magnetization direction:Axially; Radially or Speciarequirement

Detailed parameters

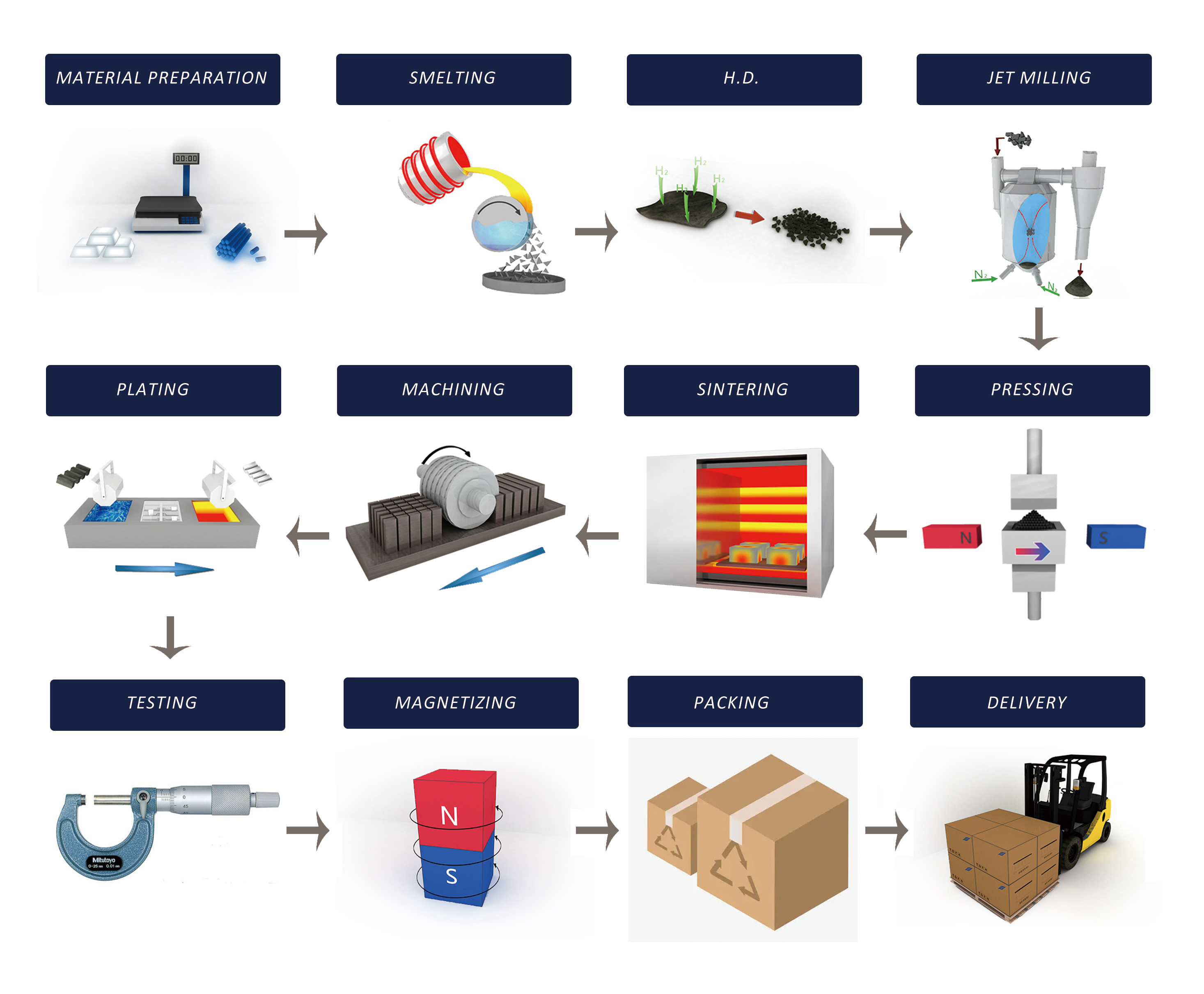

Product Flow Chart

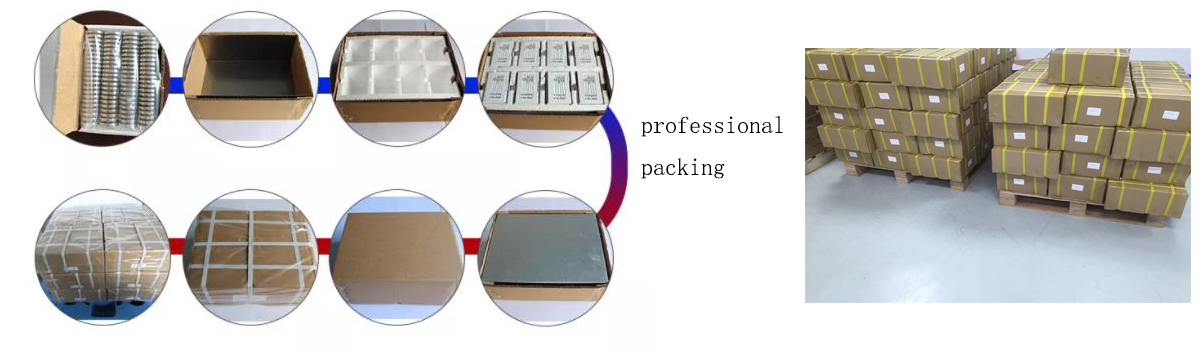

Why Choose Us

Company Show

Feedback