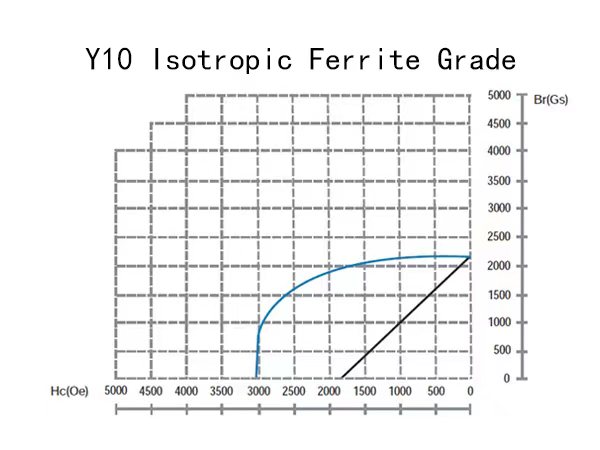

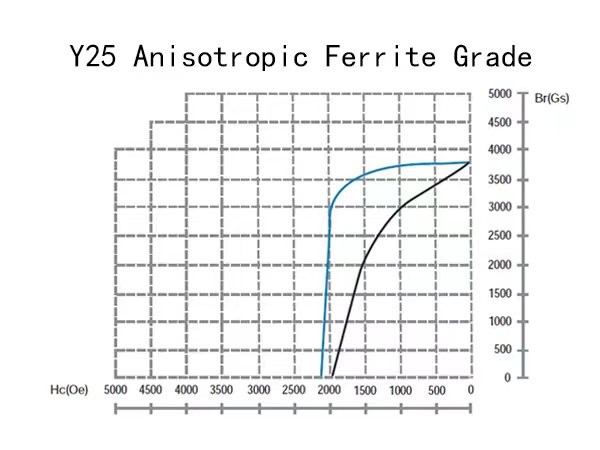

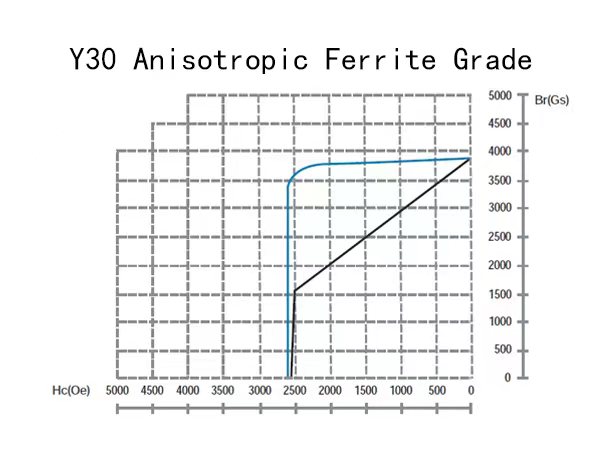

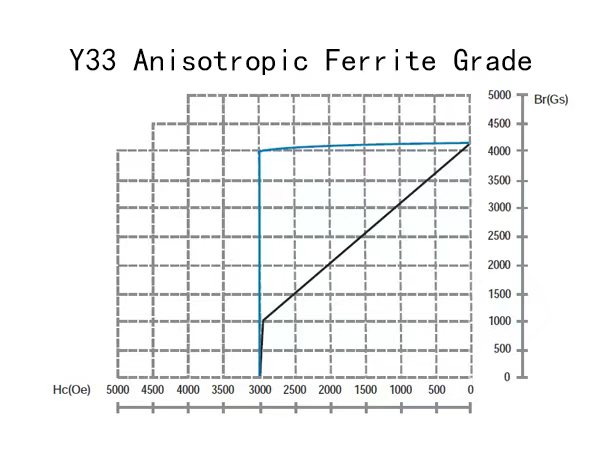

Ferrite(Ceramic)Magnet is manufactured from oxide materials using powder metallurgical process.Ceramic magnet is most widely used because ofits low costhigh-energygood electric insulation and excellent resistance to demagnetization. The most common type of ceramic magnets are anisotropic strontium,anisotropic barium and isotropic barium magnet.

Ferrite(Ceramic) Magnets are essentially composed of oxide materials with Barium Carbonate or Strontium Carbonate,manufactured under a powder metallurgical process.The feature of low recoil permeability,along with the high coercive force makes them highly resistant to demagnetizingfields. In addition,their relatively low specific density and economical cost are also very attractive to the magnet designers.

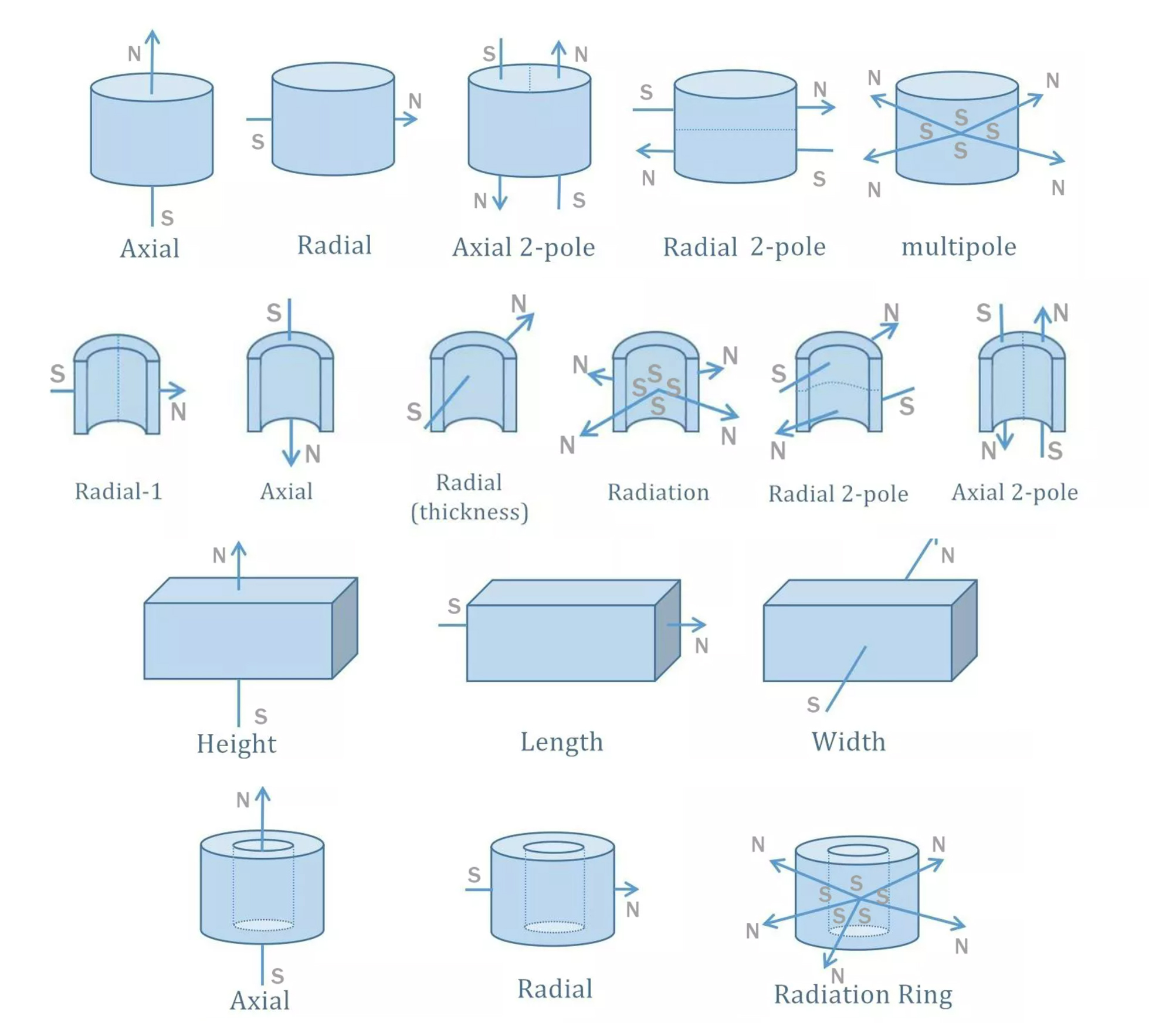

When designing the ferrite magnets for a particular application,primary consideration should be given to its shape limitation due to the powder metallurgical manufacturing process and the temperature dependence of ferrite materials.Ferrite Magnets has good anti-corrosion performance,no surface treatment needed.At present, we have put our emphasis on the application for electric motors, magnetic separators, magnetic resonance imagingand automotive sensors.

Main products includes: hard ferrite arc or segmentring magnets,rectangular magnets, ferrite power etc.Ferrite magnets have the following advatages: high coercive force,high electric resistance,long-time stability, and economical price.Meanwhile, we can manufacture new tools according to customersdemand.

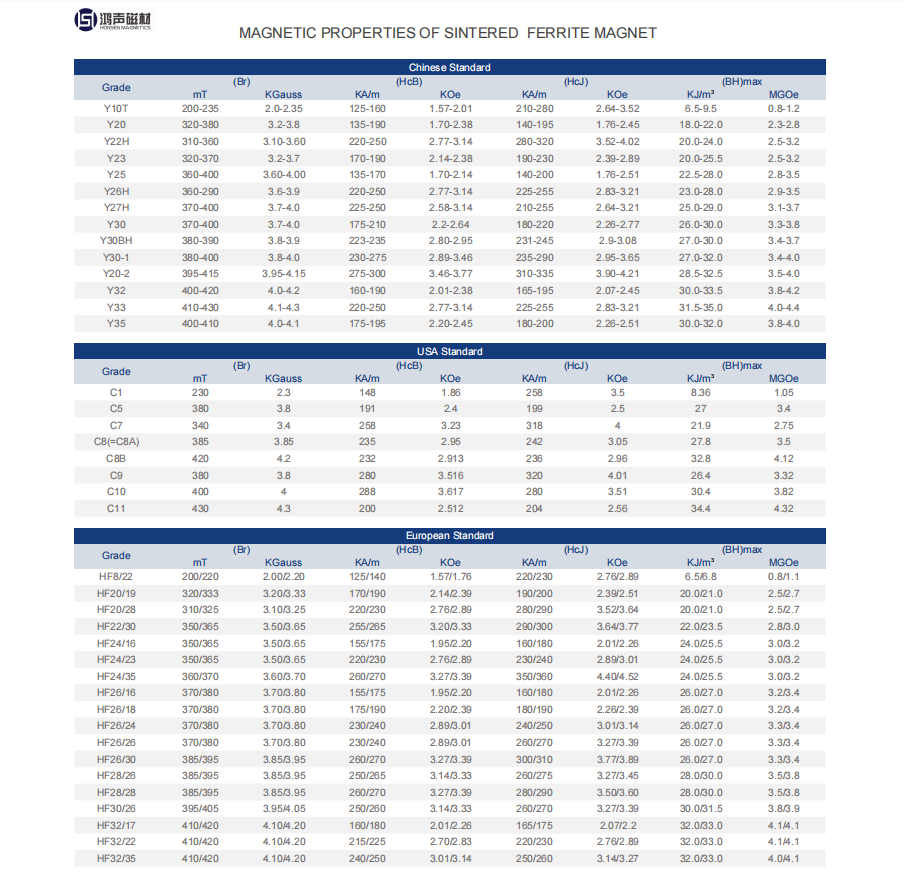

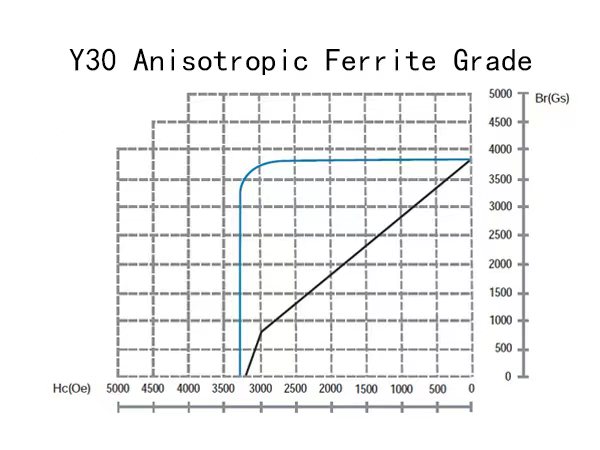

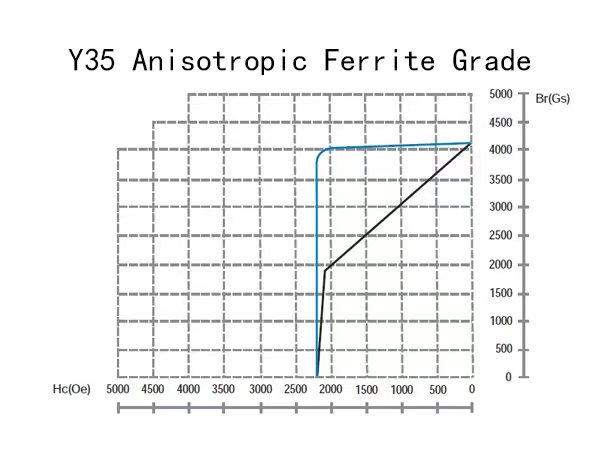

Detailed parameters

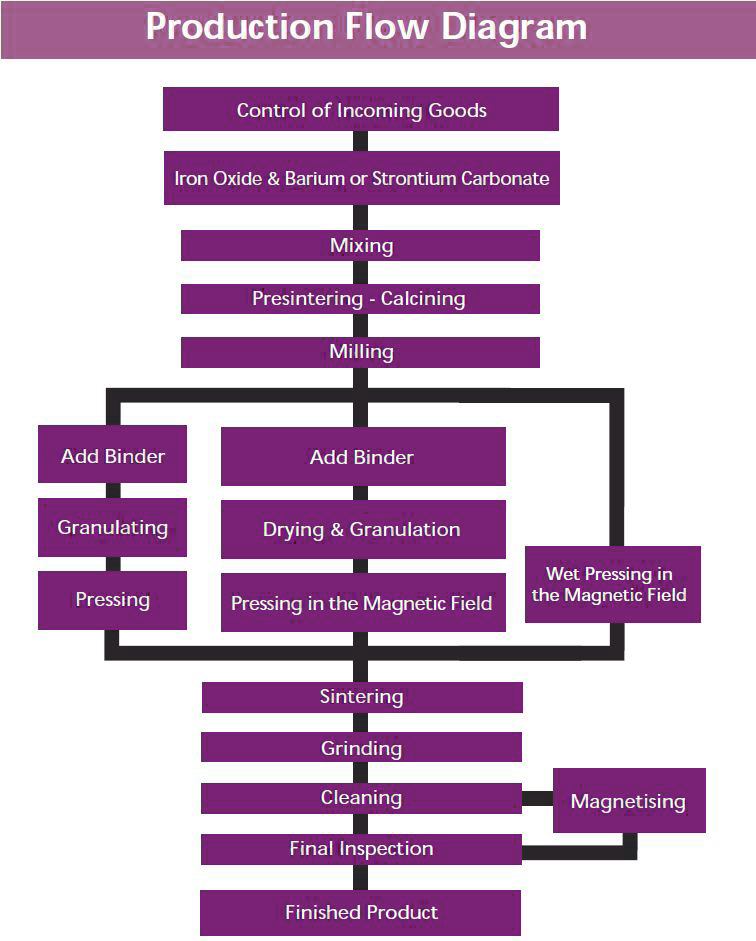

Product Flow Chart

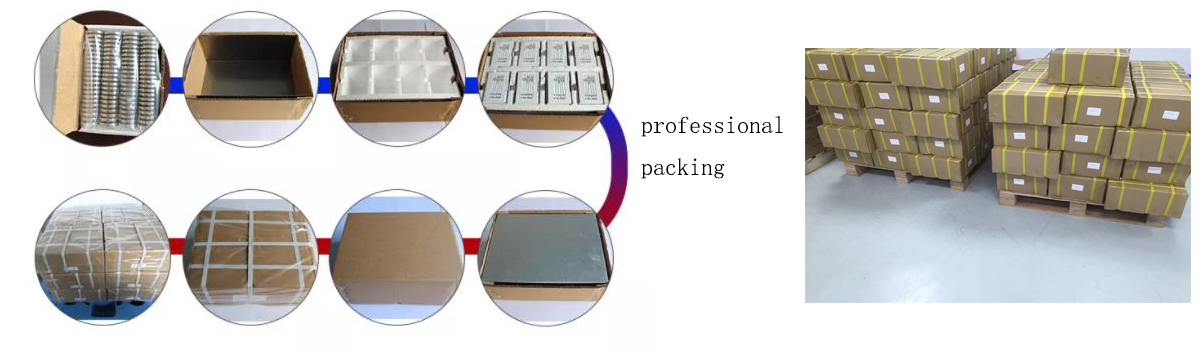

Why Choose Us

Company Show

Feedback