Introduction of Pot Magnets

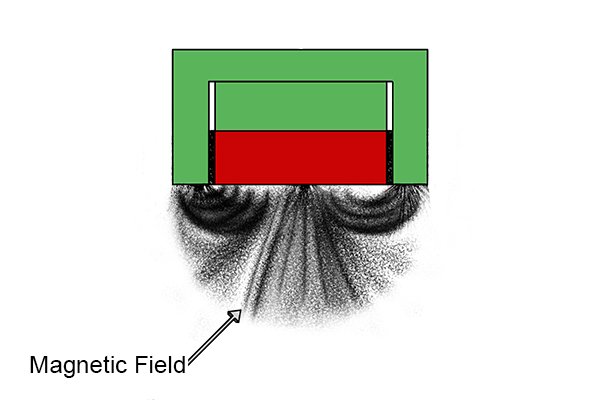

Pot magnets are magnetic assemblies composed of a metal "pot" and permanent magnets. This magnet assembly may have a hole, thread, or detachable hook in the middle. When the magnet comes into close touch with a thick iron surface, the steel pot increases its adhesive force. You may strain it significantly less if there is no direct touch with the counterpart, or if the steel plate is thin, coated, or rough. As the magnetic field is concentrated in one area, the magnet will not be allowed to attract ferromagnetic materials over a large air gap. This is because the magnetic field lines will not stretch out beyond the sides of the shell.

Magnetic Assemblies have been specifically designed to protect delicate Permanent Magnets from breaking due to repetitive impacts, while simultaneously significantly enhancing their magnetic strength. Unlike individual magnets, Pot Magnets possess a substantially more powerful magnetic force, with the metal pot playing a crucial role in forming the magnetic circuit. This unique arrangement maximizes the utilization of the magnetic force, ensuring optimal performance. Pot Magnets offer an incredibly efficient solution for securely hanging or attaching items to metal surfaces without causing any damage. They find wide usage in various industries such as construction, engineering, and automotive, as well as in common settings like workplaces, homes, and warehouses. Their applications encompass securing, holding, mounting, lifting, and transporting various objects.

Our selection of Pot Magnets is extensive, encompassing a wide array of diameters and heights. Actually, we provide Pot Magnets in various finishes, including silver (chrome, zinc, or nickel), white paint, red paint, black rubber coating, and ferritic stainless steel. It's important to note that we offer a much broader range of sizes and pull forces than what is shown on our website. In the event that you cannot find a Pot Magnet with the desired size or performance, we kindly request you to reach out to us for our comprehensive brochure range.

We provide a variety of Pot Magnets, including:

NdFeB Pot Magnets are best for maximum pull strength with a small size. With their strong magnetic properties and unique design, they provide unparalleled performance, making them the ideal solution for applications where space is limited but strong magnetic force is crucial.

Ferrite Pot Magnets are versatile and with low cost, making them suitable for various applications. Their corrosion resistance makes them perfect for marine environments, while their ability to withstand higher temperatures ensures reliable performance.

SmCo Pot Magnets are well-suited for use in extreme temperatures and exhibit excellent resistance to marine environments and corrosion, making them versatile for various applications.

Alnico Pot Magnets are suitable for applications with high temperatures and require minimal pull force change with varying temperatures. Additionally, they are ideal for use in corrosion-resistant applications.

Deep Pot Magnet consists of a strong magnet embedded within a steel pot or casing. Deep Pot Magnets are often used in holding, lifting, and positioning tasks, such as attaching objects to metal surfaces, securing signs or fixtures, or holding tools or components.

Channel Magnets are made up of a Ferrite or Neodymium, and a steel cup or channel. These magnets are highly versatile and can be used for various purposes, including holding and positioning objects. They are designed with mounting holes, allowing them to be easily attached by screws or bolts. The core of the Channel Magnets can use either Ceramic or NdFeB Magnets.

Fishing Magnets, also called as Salvage Magnets, Search Magnets, or Retrieving Magnets, which look like pot magnets, made up of rubber and steel housings. Their sizes are usually larger than pot magnets, and the fishing magnets are used for searching iron things in river, sea, or other places.

Rubber Coated Magnets generate concentrated and shallow magnetic fields on their application surfaces. They provide exceptional grip strength on thin-painted body metal and can prevent damage to the body paint. The rubber surface also enhances the magnet's ability to resist lateral displacement by generating suction.

Countersunk Magnets are specifically designed with a countersunk hole that perfectly fits a screw, whether it's a disc, block, or arc magnet made from Neodymium, Ferrite, or SmCo. These magnets are equipped with countersunk or counterbore mounting holes, allowing them to be easily and securely screwed into place, with the screw head sitting flush with the magnet surface.

We specialize in the production of Customized Pot Magnets tailored specifically to meet our customers' individual design requirements. Whether you have an original design in mind or seek to modify an existing product from a mature market, we possess the expertise and resources to fulfill your needs.

Application of Pot Magnets

Pot Magnets are widely used due to their strong magnetic field and versatility. They are commonly employed for holding and mounting objects such as magnetic locks, signs, and fixtures. Pot Magnets are also used for metal retrieval in fishing and salvage operations. They are effective in magnetic closures for doors and cabinets. In workshops and industrial settings, they securely hold tools and equipment. Pot Magnets are crucial in magnetic separators for industries like recycling and mining. They are used in magnetic clamping systems for machining and welding applications.

WHY CHOOSE US

We Provide ONE-STOP-SOLUTIONS

Honsen Magnetics, as a professional supplier of permanent magnets and magnetic assemblies, specializing in high-quality NdFeB Magnets, magnetic products such as Motor Rotors, Magnetic Couplings, Magnetic Filters, Pot Magnets, more than 80% of the company's products are exported products, mainly exported to America, Europe, Southeast Asia, and other regions.

PRODUCTION FACILITIES

Since our establishment, prioritizing the quality of our products has always been our topmost concern. We strive relentlessly to enhance both our products and production processes, assuring you that you will receive the requested products of the utmost quality. This is not merely a claim but a commitment we uphold on a daily basis. Our team comprises experienced professionals who excel at every stage of production.

To ensure product and process excellence, we employ Advanced Product Quality Planning (APQP) and Statistical Process Control (SPC) systems, which diligently monitor and manage conditions during pivotal manufacturing stages. Rest assured, our dedication to delivering exceptional products remains unwavering. By continuously striving for improvement and implementing stringent quality control measures, we stand by our promise of providing you with the finest products available.

With our proficient workforce and robust quality management systems, we are confident in our ability to consistently meet and exceed your expectations. Your satisfaction with our high-quality offerings is our ultimate goal.

QUALITY & SAFETY

Quality management is the essence of our company fabrics. We see quality as the heartbeat and compass of our organization. Our dedication goes beyond mere paperwork - we intricately integrate our Quality Management System into our processes. Through this approach, we ensure our products consistently meet and exceed our customers' expectations, reflecting our commitment to excellence.

PACKING & DELIVERY

TEAM & CUSTOMERS

The heart of Honsen Magnetics beats to a double rhythm: the rhythm of ensuring customer happiness and the rhythm of ensuring safety. These values go beyond our products to resonate in our workplace. Here, we celebrate every step of our employees' journey, viewing their progress as the cornerstone of our company's lasting progress.