Types of Magnet Materials

Magnets can be classified into three types based on their properties and composition. These three types are as follows:

- Temporary Magnets

- Permanent Magnets

- Electromagnets

Each type of magnet plays a vital role in our quest for sustainability. With their diverse range of applications, magnets contribute to the development of greener technologies, conserve resources, and promote a more sustainable society.

Permanent Magnets creates stable magnetic field and can maintain magnetism for a long time. Such magnets are used in a wide variety of applications and by utilizing Permanent Magnets, we can create efficient and sustainable technologies that reduce energy consumption and promote a green environment.

Permanent Magnets generate a magnetic field and are unique in that, once produced, they provide magnetic flux with no energy input and therefore zero operating costs. The magnetic field can be maintained even in the presence of a reverse magnetic field, but if the reverse magnetic field is strong enough, the magnetic domains within the Permanent Magnets will follow the reverse magnetic field, causing the permanent magnet to become demagnetized.

Permanent Magnets is essentially an energy storage device. This energy is injected into the magnet when it is first magnetized, and if manufactured and handled properly, it remains in the magnet indefinitely. The magnet's energy never runs out and is always available. This is because magnets do not have a network effect on their surroundings. Instead, magnets use their energy to attract or repel other magnetic objects, thereby aiding in the conversion between electrical and mechanical energy.

Motors that use Permanent Magnets are more efficient than those that do not.

Currently, all known strong magnets contain Rare Earth Elements, and they are central components of things like electric cars and wind turbines.

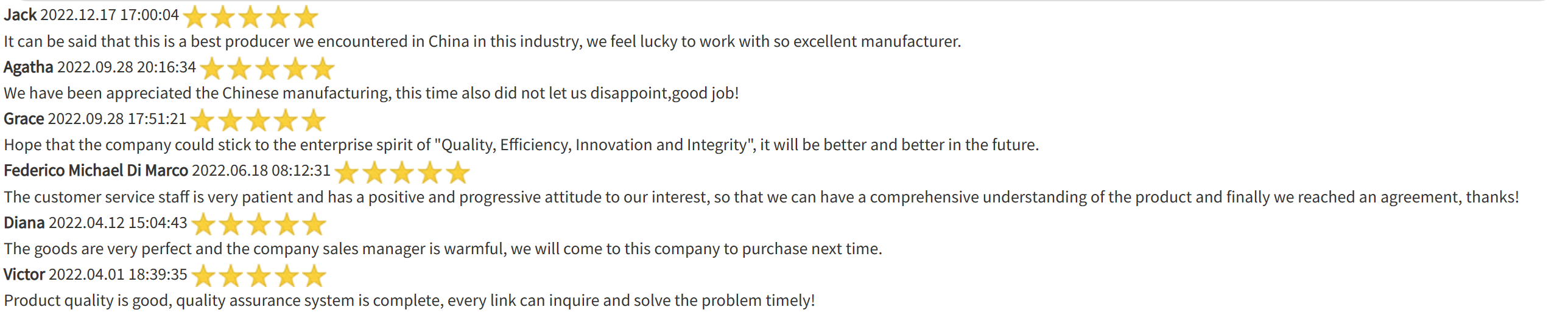

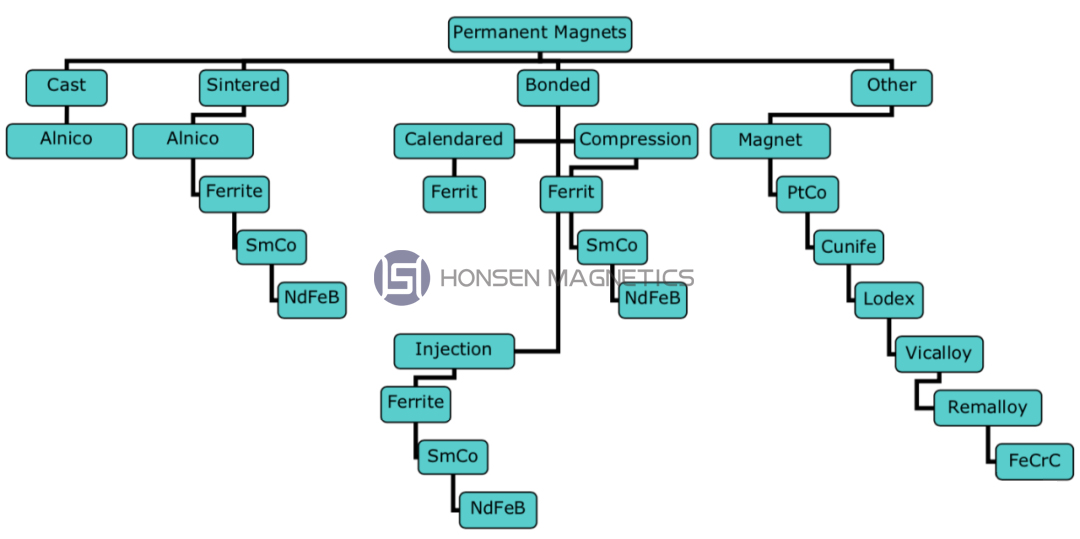

By convention, Permanent Magnets can be divided into 4 types:

Aluminum Nickel Cobalt (AlNiCo)

Ceramic or Ferrite (Ferrite Magnet)

According to the type of process, magnets can be divided into cast, sintered, and bonded magnets.

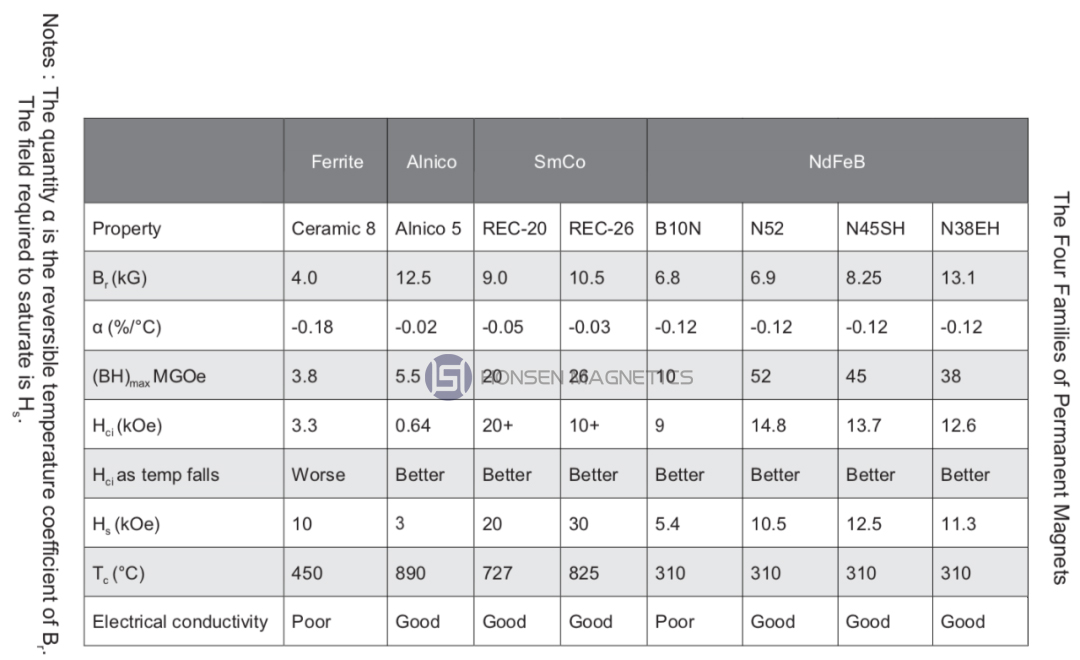

Neodymium Iron Boron (NdFeB) Magnets

Neodymium Magnet is a type of anisotropic alloy that contains Neodymium (Nd), Iron (Fe), and Boron (B), and it's the strongest available magnet alloy at up to 55MGOe. It has the remarkable ability to attract objects that weigh over 600 times its own weight. To prevent corrosion, Sintered Neodymium Magnet is coated with materials like nickel, copper, zinc, epoxy, etc. Although Neodymium Magnet is somewhat brittle (though not as much as SmCo Magnet), it undergoes machining and polishing operations to achieve the required dimensional tolerances before being magnetized using mechanical devices. In recent years, there has been a significant increase in the commercial demand for Neodymium Magnet. This surge in demand can be attributed to the discovery of its exceptionally strong magnetism. Neodymium Magnet, often abbreviated as NdFeB, is highly resistant to demagnetization, making it a popular choice in various industries. Interestingly, even a small Neodymium Magnet can possess as much energy as a large non-Neodymium Magnet. Moreover, one of its key advantages is its reasonable price compared to other types of magnets.

Honsen Magnetics can optimize performance and cost with Neo magnets in grades from 30 to 55MGOe and operating temperatures up to 230°C/446°F.

Samarium Cobalt (SmCo) Magnets

Samarium Cobalt (SmCo) Magnets are a type of Rare Earth Magnet that finds frequent use in high-temperature applications. They possess the second-highest strength, only falling behind Neodymium Magnets. This magnet is an anisotropic alloy combining samarium (Sm) and cobalt (Co) elements, and it comes in two variations: SmCo5 and Sm2Co17. SmCo magnets demonstrate exceptional resistance to demagnetization. While they have relatively low mechanical strength and higher costs, they can operate at temperatures up to 350 °C, surpassing most other permanent magnets. In comparison to Neodymium Magnets, Samarium Cobalt Magnets show superior resistance to corrosion.

In many applications, SmCo Magnets do not require additional coating or plating. However, it is important to consider factors like acidic or moist environments, as well as vacuum environments. The use of metal coating or protective measures helps maintain the magnet's cleanliness. The remarkable resistance of Samarium Cobalt to environmental factors has positioned it as an excellent choice for applications in medical and aerospace fields. For medical applications, these magnets may be protected by Parylin coating—a type of polymer coating.

Honsen Magnetics can help optimize performance and cost with SmCo Magnets in grades from 16 to 35 MGOe (1:5 and 2:17) and temperatures up to 350°C/662°F.

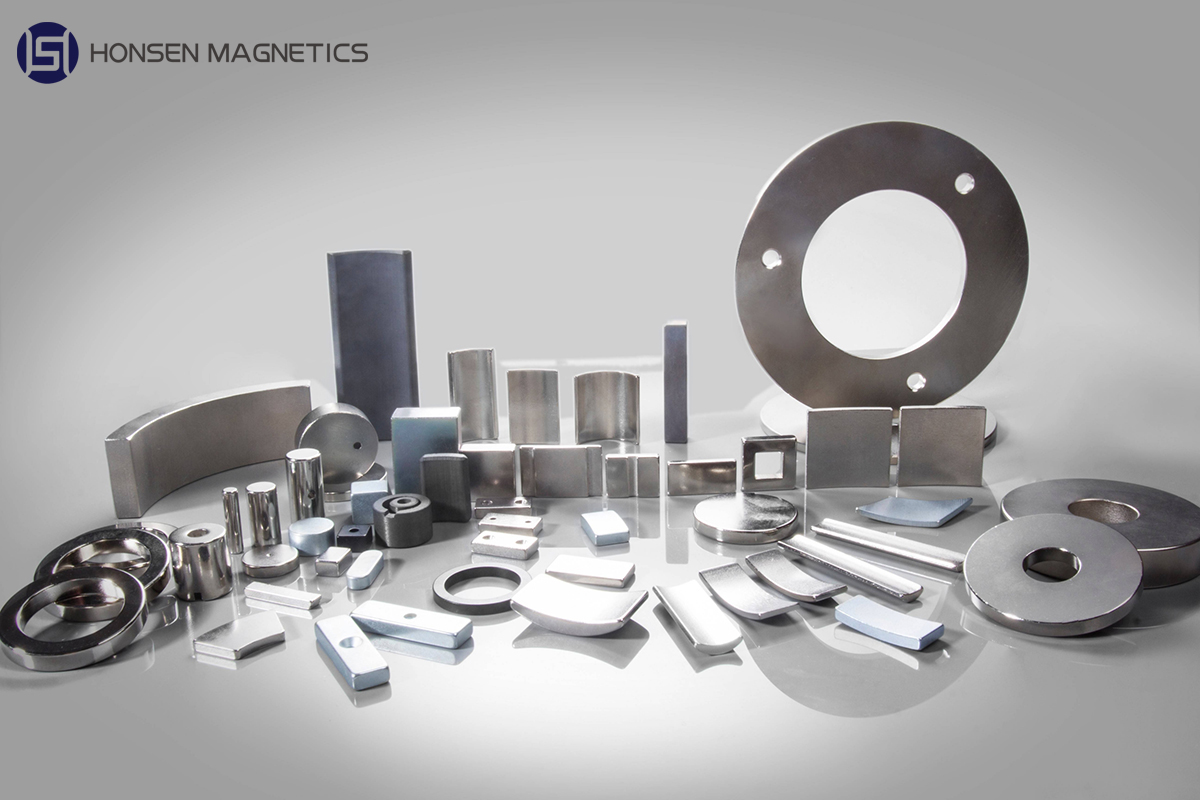

AlNiCo Magnets

Alnico Magnets, ranked third among Permanent Magnets in terms of strength, are composed primarily of aluminum (Al), nickel (Ni), and cobalt (Co). They are available in two forms: Cast and Sintered. The cast type of Alnico Magnet offers the advantage of being able to be produced in complex shapes. The sintered type provides a greater level of uniformity in the magnetic field due to the absence of voids, unlike the cast type.

However, Alnico Magnets have a weakness in their low Coercive Force (Hc), which makes them prone to being easily demagnetized in the presence of neutralizing forces. Despite their high remanence (Br), these magnets have lower production capability compared to other magnets due to their low Hc content. Alnico magnets exhibit high resistance to corrosion, but their high hardness and brittleness make them difficult to machine. AlNiCo Magnets find application in corrosive and high-heat environments, with a maximum operating temperature of 977°F (550°C). They are commonly used in Electric Motors, Military & Aerospace Sensors, Trigger Hall and Reed Sensors, and High-Temp Holding Assemblies.

Honsen Magnetics can help optimize performance and cost with a variety of Cast and Sintered Alnico grades, including Alnico 2, Alnico 5, Alnico 5-7, Alnico 8, and Alnico 9.

Ferrite (Ceramic) Magnets

Ferrite or Ceramic Magnets, ranked fourth in terms of strength among Permanent Magnets, are composed of approximately 80% iron oxide and 20% strontium oxide or barium oxide.

Ferrite Magnets exhibit moderate remanence induction but boast several advantages, including resistance to demagnetization and corrosion, as well as the absence of eddy current losses.

Ferrite Magnets are readily available and cost-effective.

Due to their beneficial characteristics, Ferrite Magnets are commonly used in various applications such as motors, speakers, and work-holding assemblies. They are highly recommended for high-volume applications due to their cost-effectiveness. Furthermore, Ferrite Magnet alloys demonstrate impressive resistance to external demagnetization fields.

Honsen Magnetics can help optimize performance and cost with a variety of grades, including Ceramic 1, Ceramic 5, Ceramic 8, and Ceramic 8B with a max operating temperature of 482°F/250°C

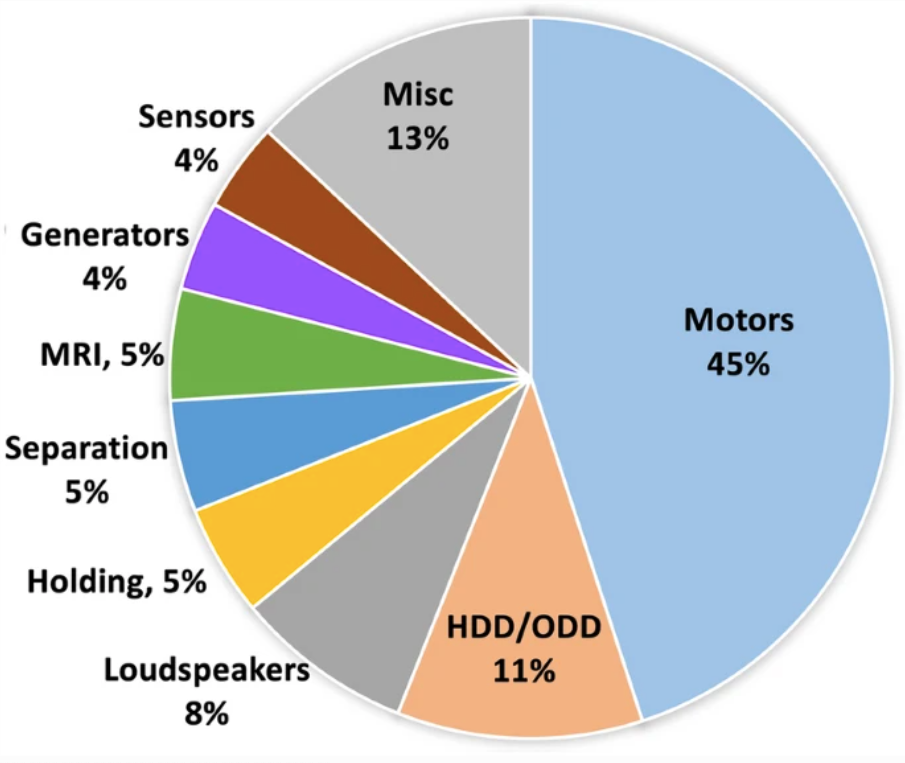

Typical Applications of Permanent Magnets

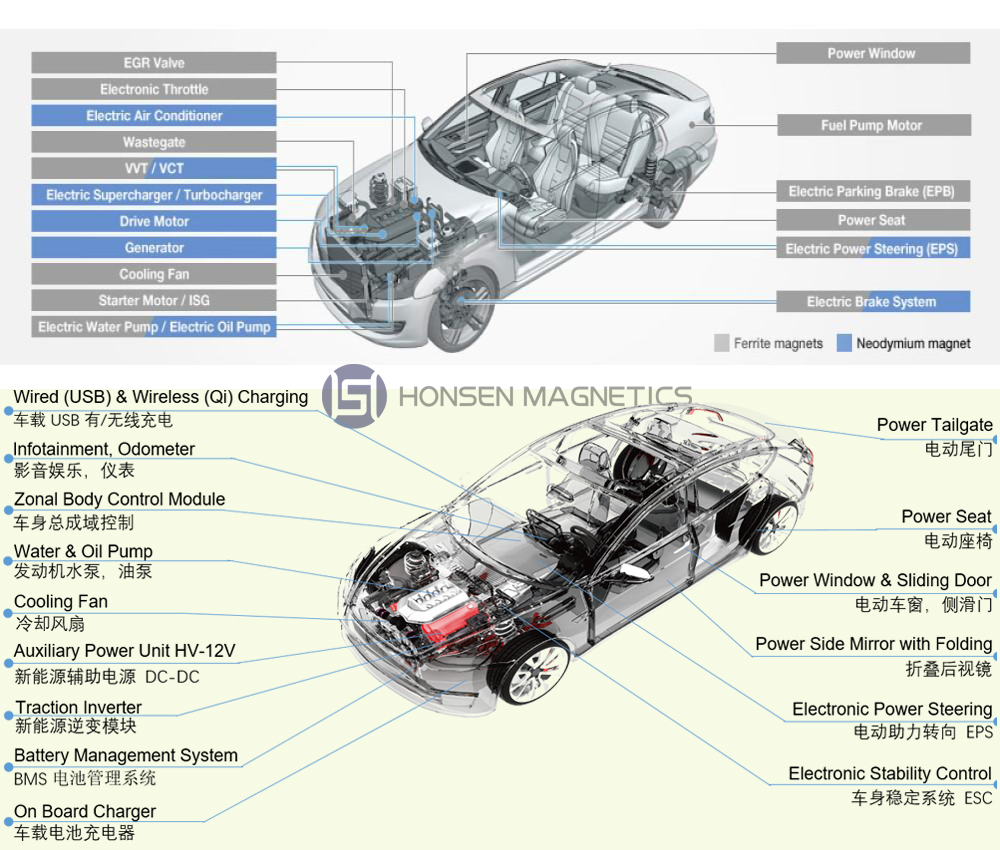

Magnets used in cars including air conditioning, brake systems, drive motors, oil pumps

Magnets are widely used in mobile phone speakers, headphones, vibration motors, electromagnets, hair dryers, fans, refrigerators, washing machines

Magnets are used in consumer electronics products

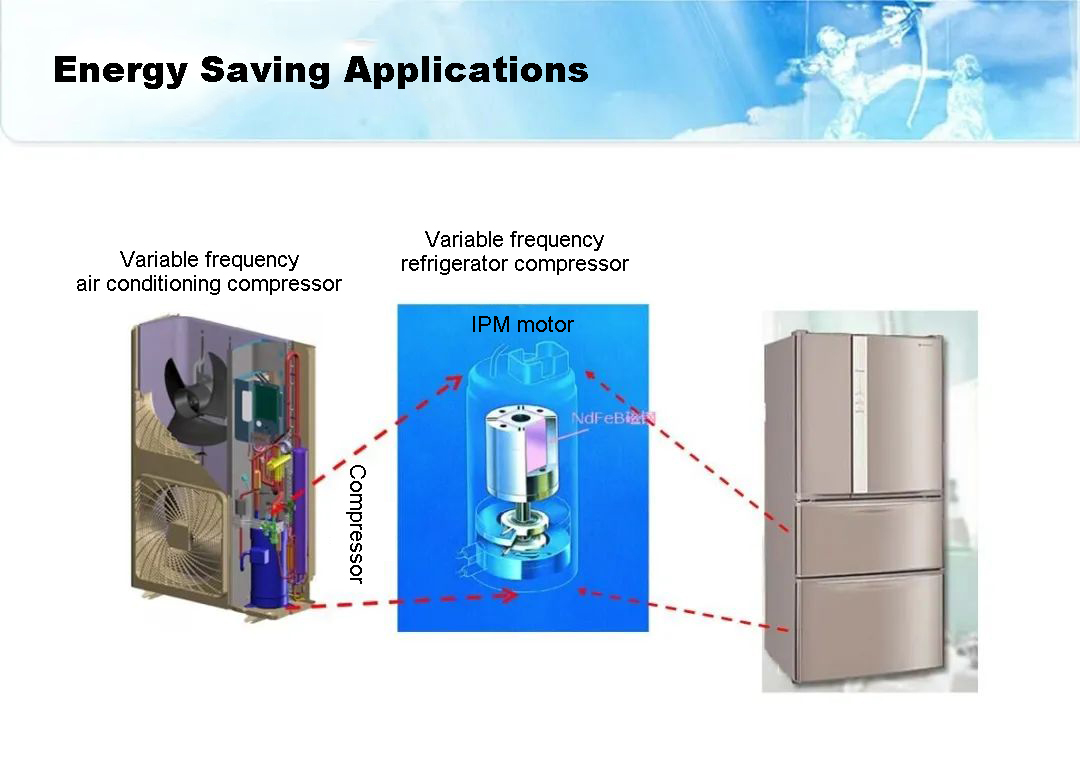

Magnets are applied to refrigerator compressor motors

WHY HONSEN MAGNETICS

With over a decade of experience, Honsen Magnetics has excelled in the manufacturing and trading of Permanent Magnets and Magnetic Assemblies. We offer a complete range of magnetic products, including Neodymium Magnets, Samarium Cobalt Magnets, Alnico Magnets, Ferrite Magnets, and various application-specific magnetic components, enabling us to provide comprehensive solutions to our customers.

At Honsen Magnetics, we are capable of producing custom Permanent Magnets and Magnetic Assemblies, whether in large volumes or for small and unique projects. Our commitment goes beyond manufacturing magnets – we prioritize delivering high-quality products with short lead times to reduce costs and increase customer satisfaction.

Customer-centricity is the cornerstone of our operations at Honsen Magnetics. We prioritize our customers' needs and satisfaction, ensuring exceptional products and services throughout their entire journey. By consistently offering reasonable prices and maintaining excellent product quality, we have earned the trust and positive feedback of our customers, solidifying our position in the industry.

OUR ADVANTAGES

- More than 10 years experience in permanent magnetic products industry

- Over 5000m2 factory is equipped with 200 advanced Machines

- Have a complete production line from machining, assembling, welding, injection molding

- With 2 production plants, 3000 tons/year for magnets and 4m units/month for magnetic products

- Having strong R&D team can provide perfect OEM&ODM service

- Have the certificate of ISO 9001, IATF 16949, ISO14001, ISO45001, REACH, and RoHs

- Strategic cooperation with the top 3 rare blank factories for raw materials

- High rate of automation in Production & Inspection

- 0 PPM for Magnets & Magnetic Assemblies

- FEA simulation to calculate and optimize magnetic circuits

- Skilled workers & continuous improvement

- We only export qualified products to customers

- We enjoy a hot market in most parts of Europe, America, Asia & others

- Fast shipping & worldwide delivery

- Offer free magnetic solutions

- Bulk discounts for larger orders

- Serve ONE-STOP-SOLUTION ensure efficient & cost-effective purchasing

- 24-hour online service with first-time response

- Work with big customers & small ones without MOQ

- Offer all kinds of payment methods

PRODUCTION FACILITIES

Since our establishment, prioritizing the quality of our products has always been our topmost concern. We strive relentlessly to enhance both our products and production processes, assuring you that you will receive the requested products of the utmost quality. This is not merely a claim but a commitment we uphold on a daily basis. Our team comprises experienced professionals who excel at every stage of production.

To ensure product and process excellence, we employ Advanced Product Quality Planning (APQP) and Statistical Process Control (SPC) systems, which diligently monitor and manage conditions during pivotal manufacturing stages. Rest assured, our dedication to delivering exceptional products remains unwavering. By continuously striving for improvement and implementing stringent quality control measures, we stand by our promise of providing you with the finest products available.

With our proficient workforce and robust quality management systems, we are confident in our ability to consistently meet and exceed your expectations. Your satisfaction with our high-quality offerings is our ultimate goal.

QUALITY & SAFETY

Quality management lies at the core of our organization, forming the foundation on which we thrive. At Honsen Magnetics we firmly believe that quality is not merely a theoretical construct; it is the driving force behind every decision and action we take.

Our unwavering commitment to excellence manifests in all aspects of our operations. We have adopted a comprehensive approach to quality management, seamlessly incorporating it into every facet of our organization. This holistic integration ensures that quality is not an afterthought but an inherent aspect of our processes and products. From raw materials procurement to production and customer service, our quality management system permeates every stage. Our paramount goal is to consistently surpass the expectations of our customers. By adhering to stringent quality control measures and leveraging cutting-edge technology, we meticulously craft products of unrivaled excellence. Our dedication to exceeding customer expectations is not a mere statement but woven into the fabric of our organization.

Our success hinges on our unwavering dedication to quality management. By integrating it seamlessly into our operations, we consistently deliver exceptional products that reflect our steadfast commitment to excellence.

PACKING & DELIVERY

TEAM & CUSTOMERS

At Honsen Magnetics, we believe that the key to our success lies in our ability to satisfy our customers and maintain excellent safety practices. However, our commitment to perfection doesn't stop there. We also prioritize the personal development of our workforce.

By creating a nurturing environment, we encourage our employees to grow both professionally and personally. We provide them with opportunities for training, skill enhancement, and career advancement.

We empower our workforce to reach their full potential. We recognize that investing in personal growth is vital for long-term success. As individuals within our organization develop their skills and knowledge, they become more valuable assets, contributing to the overall strength and competitiveness of our business.

By promoting personal development within our workforce, we not only lay the foundation for our own enduring success but also foster a culture of continuous improvement. Our commitment to satisfying customers and ensuring safety is complemented by our dedication to the growth and development of our employees. These pillars form the cornerstone of our business.

CUSTOMERS' FEEDBACK