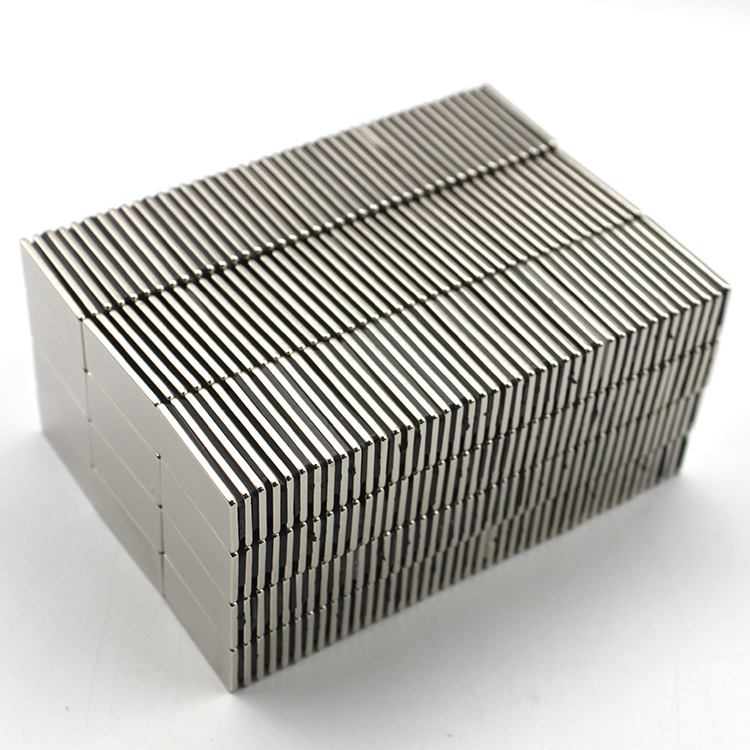

Honsen offers neodymium magnets in square and rectangular blocks. These neodymium Iron Boron magnets are widely used for motor, sensor and holding applications. Neodymium block magnet is the most powerful rare earth magnet, which provides huge cost and performance return. It has the highest field / surface strength (Br) and high coercivity (Hcj), and can be easily machined to various shapes and sizes. It is an ideal choice from industrial and technological applications to your projects. Contact us for an efficient magnet solutions for your project.

• Neo magnets are the most powerful commercially produced magnets.

• Permanent Nib magnets are hard and brittle and may chip or break if dropped.

• Honsen Neodymium block magnets can be magnetized through the length width and thickness.

• Uncoated rare earth magnets may corrode in humid conditions.

• Operating temperatures vary among material grades. For a comparison of neodymium material grades, please visit our chart of material properties.

| N Grade Magnets | ||||||

| No | Grade | Br (kGs) | Hcb (kOe) | Hcj (kOe) | (BH)max (MGOe) | Tw (℃) |

| 1 | N55 | 14.7-15.3 | ≥10.8 | ≥11 | 52-56 | 80 |

| 2 | N52 | 14.3-14.8 | ≥10.8 | ≥12 | 50-53 | 80 |

| 3 | N50 | 14.0-14.5 | ≥10.8 | ≥12 | 48-51 | 80 |

| 4 | N48 | 13.8-14.2 | ≥10.5 | ≥12 | 46-49 | 80 |

| 5 | N45 | 13.2-13.8 | ≥11.0 | ≥12 | 43-46 | 80 |

| 6 | N42 | 12.8-13.2 | ≥11.6 | ≥12 | 40-43 | 80 |

| 7 | N40 | 12.5-12.8 | ≥11.6 | ≥12 | 38-41 | 80 |

| 8 | N38 | 12.2-12.5 | ≥11.3 | ≥12 | 36-39 | 80 |

| 9 | N35 | 11.7-12.2 | ≥10.9 | ≥12 | 33-36 | 80 |

| 10 | N33 | 11.3-11.8 | ≥10.5 | ≥12 | 31-34 | 80 |

| 11 | N30 | 10.8-11.3 | ≥10.0 | ≥12 | 28-31 | 80 |

| M Grade Magnets | ||||||

| No | Grade | Br (kGs) | Hcb (kOe) | Hcj (kOe) | (BH)max (MGOe) | Tw (℃) |

| 1 | N52M | 14.3-14.8 | ≥13.0 | ≥14 | 50-53 | 100 |

| 2 | N50M | 14.0-14.5 | ≥13.0 | ≥14 | 48-51 | 100 |

| 3 | N48M | 13.8-14.3 | ≥12.9 | ≥14 | 46-49 | 100 |

| 4 | N45M | 13.3-13.8 | ≥12.5 | ≥14 | 43-46 | 100 |

| 5 | N42M | 12.8-13.3 | ≥12.0 | ≥14 | 40-43 | 100 |

| 6 | N40M | 12.5-12.8 | ≥11.6 | ≥14 | 38-41 | 100 |

| 7 | N38M | 12.2-12.5 | ≥11.3 | ≥14 | 36-39 | 100 |

| 8 | N35M | 11.7-12.2 | ≥10.9 | ≥14 | 33-36 | 100 |

| 9 | N33M | 11.3-11.8 | ≥10.5 | ≥14 | 31-34 | 100 |

| 10 | N30M | 10.8-11.3 | ≥10.0 | ≥14 | 28-31 | 100 |

| H Grade Magnets | ||||||

| No | Grade | Br (kGs) | Hcb (kOe) | Hcj (kOe) | (BH)max (MGOe) | Tw (℃) |

| 1 | N52H | 14.2-14.7 | ≥13.2 | ≥17 | 50-53 | 120 |

| 2 | N50H | 14.0-14.5 | ≥13.0 | ≥17 | 48-51 | 120 |

| 3 | N48H | 13.8-14.3 | ≥13.0 | ≥17 | 46-49 | 120 |

| 4 | N45H | 13.3-13.8 | ≥12.7 | ≥17 | 43-46 | 120 |

| 5 | N42H | 12.8-13.3 | ≥12.5 | ≥17 | 40-43 | 120 |

| 6 | N40H | 12.5-12.8 | ≥11.8 | ≥17 | 38-41 | 120 |

| 7 | N38H | 12.2-12.5 | ≥11.3 | ≥17 | 36-39 | 120 |

| 8 | N35H | 11.7-12.2 | ≥11.0 | ≥17 | 33-36 | 120 |

| 9 | N33H | 11.3-11.8 | ≥10.6 | ≥17 | 31-34 | 120 |

| 10 | N30H | 10.8-11.3 | ≥10.2 | ≥17 | 28-31 | 120 |

| SH Grade Magnets | ||||||

| No | Grade | Br (kGs) | Hcb (kOe) | Hcj (kOe) | (BH)max (MGOe) | Tw (℃) |

| 1 | N52SH | 14.3-14.5 | ≥11.7 | ≥20 | 51-54 | 150 |

| 2 | N50SH | 14.0-14.5 | ≥13.0 | ≥20 | 48-51 | 150 |

| 3 | N48SH | 13.7-14.3 | ≥12.6 | ≥20 | 46-49 | 150 |

| 4 | N45SH | 13.3-13.7 | ≥12.5 | ≥20 | 43-46 | 150 |

| 5 | N42SH | 12.8-13.4 | ≥12.1 | ≥20 | 40-43 | 150 |

| 6 | N40SH | 12.6-13.1 | ≥11.9 | ≥20 | 38-41 | 150 |

| 7 | N38SH | 12.2-12.9 | ≥11.7 | ≥20 | 36-39 | 150 |

| 8 | N35SH | 11.7-12.4 | ≥11.0 | ≥20 | 33-36 | 150 |

| 9 | N33SH | 11.3-11.7 | ≥10.6 | ≥20 | 31-34 | 150 |

| 10 | N30SH | 10.8-11.3 | ≥10.1 | ≥20 | 28-31 | 150 |

| UH Grade Magnets | ||||||

| No | Grade | Br (kGs) | Hcb (kOe) | Hcj (kOe) | (BH)max (MGOe) | Tw (℃) |

| 1 | N45UH | 13.1-13.6 | ≥12.2 | ≥25 | 43-46 | 180 |

| 2 | N42UH | 12.8-13.4 | ≥12.0 | ≥25 | 40-43 | 180 |

| 3 | N40UH | 12.6-13.1 | ≥11.8 | ≥25 | 38-41 | 180 |

| 4 | N38UH | 12.2-12.9 | ≥11.5 | ≥25 | 36-39 | 180 |

| 5 | N35UH | 11.7-12.4 | ≥11.0 | ≥25 | 33-36 | 180 |

| 6 | N33UH | 11.4-12.1 | ≥10.6 | ≥25 | 31-34 | 180 |

| 7 | N30UH | 10.8-11.3 | ≥10.5 | ≥25 | 28-31 | 180 |

| 8 | N28UH | 10.5-10.8 | ≥9.6 | ≥25 | 26-30 | 180 |

| EH Grade Magnets | ||||||

| No | Grade | Br (kGs) | Hcb (kOe) | Hcj (kOe) | (BH)max (MGOe) | Tw (℃) |

| 1 | N42EH | 12.8-13.2 | ≥12.0 | ≥30 | 40-43 | 200 |

| 2 | N40EH | 12.4-13.1 | ≥11.8 | ≥30 | 38-41 | 200 |

| 3 | N38EH | 12.2-12.7 | ≥11.5 | ≥30 | 36-39 | 200 |

| 4 | N35EH | 11.7-12.4 | ≥11.0 | ≥30 | 33-36 | 200 |

| 5 | N33EH | 11.4-12.1 | ≥10.8 | ≥30 | 31-34 | 200 |

| 6 | N30EH | 10.8-11.5 | ≥10.2 | ≥30 | 28-31 | 200 |

| 7 | N28EH | 10.4-10.9 | ≥9.8 | ≥30 | 26-29 | 200 |

| AH Grade Magnets | ||||||

| No | Grade | Br (kGs) | Hcb (kOe) | Hcj (kOe) | (BH)max (MGOe) | Tw (℃) |

| 1 | N38AH | 12.2-12.5 | ≥11.4 | ≥35 | 36-39 | 240 |

| 2 | N35AH | 11.6-12.3 | ≥10.9 | ≥35 | 33-36 | 240 |

| 3 | N33AH | 11.4-12.1 | ≥10.7 | ≥35 | 31-34 | 240 |

| 4 | N30AH | 10.8-11.5 | ≥10.2 | ≥35 | 28-31 | 240 |

Neodymium magnets are often assembled into products using strong adhesives such as Loctite 326 (Adhesive with metal materials and magnets). Make sure that all contact surfaces are clean and dry prior to bonding. Other glue types are always used up to the materials which magnets are applied with. For more information, please contact our experts.

-Life Consumption: Clothes, Bag, Leather Case, Cup, Glove, Jewelry, Pillow, Fish Tank, Photo Frame, Watch;

-Electronic Product: Keyboard, Display, Smart Bracelet, Computer, Mobile Phone, Sensor, GPS Locator, Bluetooth, Camera, Audio, LED;

-Home-based: Lock, Table, Chair, Cupboard, Bed, Curtain, Window, Knife, Lighting, Hook, Ceiling;

-Mechanical Equipment & Automation: Motor, Unmanned Aerial Vehicles, Elevators, Security Monitoring, Dishwashers, Magnetic Cranes, Magnetic Filter.

Please use caution when handling magnetized neodymium magnets, their exceptional magnetic force may cause them to attract to metal (or to each other) so strongly that fingers in their path could prove painful.