Magnetic Materials

With rich industry experience, Honsen Magnetics has become a trusted and reliable supplier of magnetic materials. We offer a wide range of magnetic materials, including Neodymium magnets, Ferrite / Ceramic magnets, Alnico magnets and Samarium Cobalt magnets. These materials have a variety of applications in the electronics, automotive, aerospace, medical, and energy industries. We also offer magnetic materials such as magnetic sheets, magnetic strips. These materials are used for a wide range of applications, including advertising displays, labeling, and sensing. Neodymium magnets, also known as rare earth magnets, are the strongest permanent magnets available. With their exceptional strength, they are suitable for applications requiring high holding force, such as electric motors, generators and magnetic therapy equipment. Ferrite magnets, on the other hand, are cost-effective and have good resistance to demagnetization. They are widely used in applications that do not require high magnetic field strengths, such as loudspeakers, refrigerator magnets, and magnetic separators. For special applications requiring high temperature and corrosion resistance, our Samarium Cobalt magnets are ideal. These magnets retain their magnetism in extreme environments, making them suitable for aerospace, automotive and military applications. If you are looking for a magnet with excellent stability at high temperatures and maximum operating temperatures, our AlNiCo magnets are for you. These magnets are commonly used in sensing devices, instruments and security systems. Our flexible magnets are versatile and convenient. They are easily cut, bent and twisted into a variety of shapes, making them ideal for advertising displays, signage and crafts.-

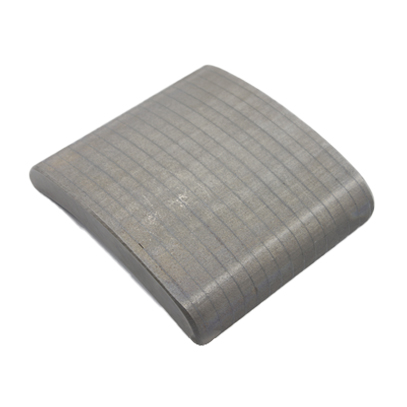

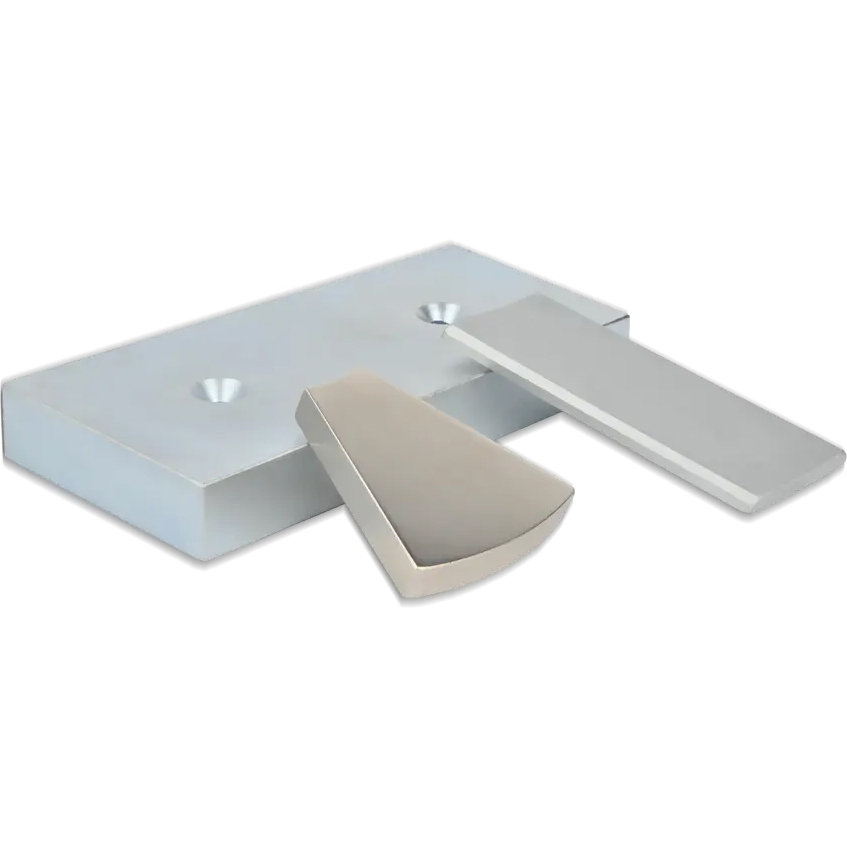

Laminated Permanent Magnets to reduce Eddy Current Loss

The purpose to cut a whole magnet into several pieces and apply the together is to reduce eddy loss. We call this kind magnets “Lamination”. Generally, the more pieces, the better the effect of eddy loss reduction. The lamination will not deteriorate the overall magnet performance, only the flux will slightly affected. Normally we control the glue gaps within a certain thickness using special method to control each gap has the same thickness.

-

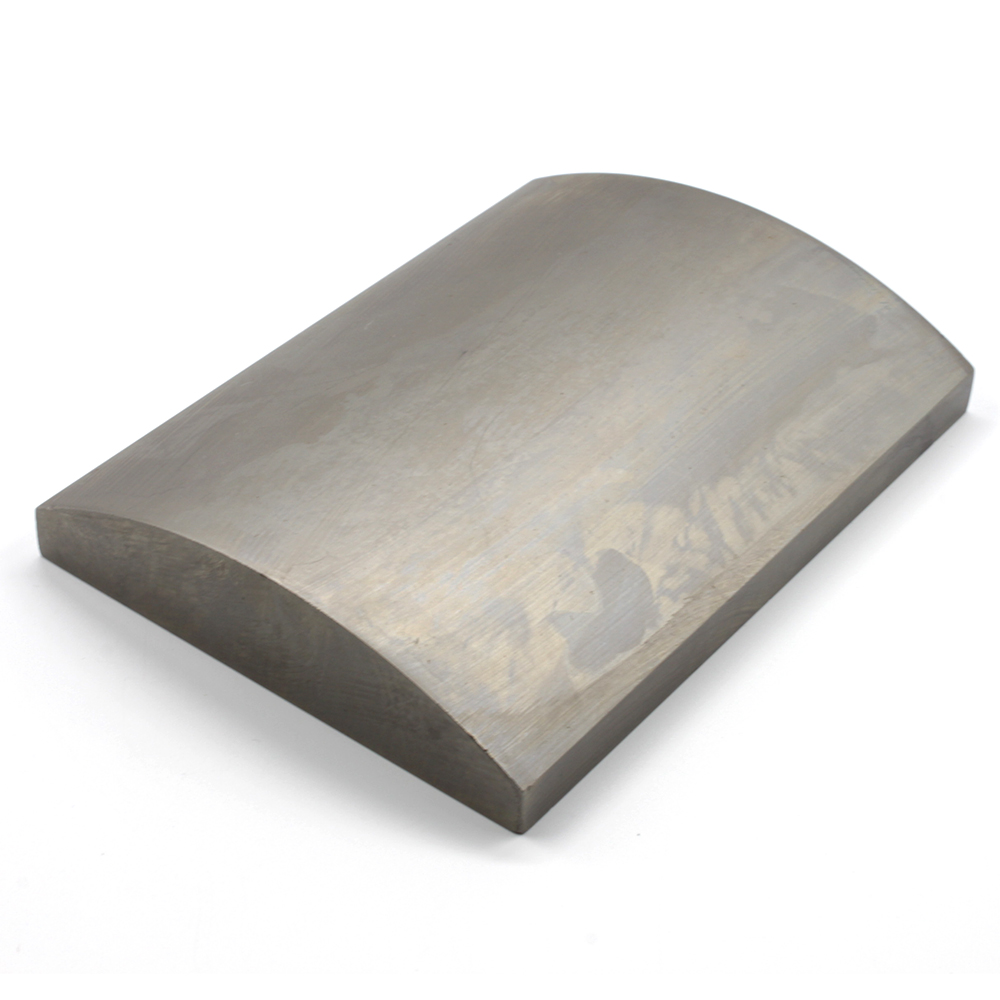

N38H Neodymium Magnets for Linear Motors

Product Name: Linear Motor Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Neodymium block magnet or customized -

Halbach Array Magnetic System

Halbach array is a magnet structure, which is an approximate ideal structure in engineering. The goal is to generate the strongest magnetic field with the smallest number of magnets. In 1979, when Klaus Halbach, an American scholar, conducted electron acceleration experiments, he found this special permanent magnet structure, gradually improved this structure, and finally formed the so-called “Halbach” magnet.

-

Rare Earth Magnetic Rod & Applications

Magnetic rods are mainly used to filter iron pins in raw materials; Filter all kinds of fine powder and liquid, iron impurities in semi liquid and other magnetic substances. At present, it is widely used in chemical industry, food, waste recycling, carbon black and other fields.

-

Permanent Magnets used in Automotive Industry

There are many different uses for permanent magnets in automotive applications, including efficiency. The automotive industry is focused on two kinds of efficiency: fuel-efficiency and efficiency on the production line. Magnets help with both.

-

Servo Motor Magnets Manufacturer

The N pole and S pole of the magnet are arranged alternately. One N pole and one s pole are called a pair of poles, and the motors can have any pair of poles. Magnets are used including aluminum nickel cobalt permanent magnets, ferrite permanent magnets and rare earth permanent magnets (including samarium cobalt permanent magnets and neodymium iron boron permanent magnets). The magnetization direction is divided into parallel magnetization and radial magnetization.

-

Wind Power Generation Magnets

Wind energy has become one of the most feasible clean energy sources on earth. For many years, most of our electricity came from coal, oil and other fossil fuels. However, creating energy from these resources causes serious damages to our environment and pollute the air, land and water. This recognition has made many people to turn to green energy as a solution.

-

Neodymium (Rare Earth) Magnets for Efficient Motors

A neodymium magnet with a low degree of coercivity may begin to lose strength if heated to more than 80°C. High coercivity neodymium magnets have been developed to operate at temperatures up to 220°C, with little irreversible loss. The need for a low temperature coefficient in neodymium magnet applications has led to the development of several grades to meet specific operational requirements.

-

Neodymium Magnets for Household Appliances

Magnets are widely used for speakers in TV sets, magnetic suction strips on refrigerator doors, high-end variable frequency compressor motors, air conditioning compressor motors, fan motors, computer hard disk drives, audio speakers, headphone speakers, range hood motors, washing machine motors, etc.

-

Elevator Traction Machine Magnets

Neodymium Iron Boron magnet, as the latest result of the development of rare earth permanent magnetic materials, is called “magneto king” because of its excellent magnetic properties. NdFeB magnets are alloys of neodymium and iron oxide. Also known as Neo Magnet. NdFeB has extremely high magnetic energy product and coercivity. At the same time, the advantages of high energy density makes NdFeB permanent magnets widely used in modern industry and electronic technology, which makes it possible to miniaturize, lightweight and thin instruments, electroacoustic motors, magnetic separation magnetization and other equipment.

-

Neodymium Magnets for Electronics & Electroacoustic

When the changing current is fed into the sound, the magnet becomes an electromagnet. The current direction changes constantly, and the electromagnet keeps moving back and forth due to the “force movement of the energized wire in the magnetic field”, driving the paper basin to vibrate back and forth. The stereo has sound.

The magnets on the horn mainly include ferrite magnet and NdFeB magnet. According to the application, NdFeB magnets are widely used in electronic products, such as hard disks, mobile phones, headphones and battery powered tools. The sound is loud.

-

Permanent Magnets for MRI & NMR

The large and important component of MRI & NMR is magnet. The unit that identifies this magnet grade is called Tesla. Another common unit of measurement applied to magnets is Gauss (1 Tesla = 10000 Gauss). At present, the magnets used for magnetic resonance imaging are in the range of 0.5 Tesla to 2.0 Tesla, that is, 5000 to 20000 Gauss.