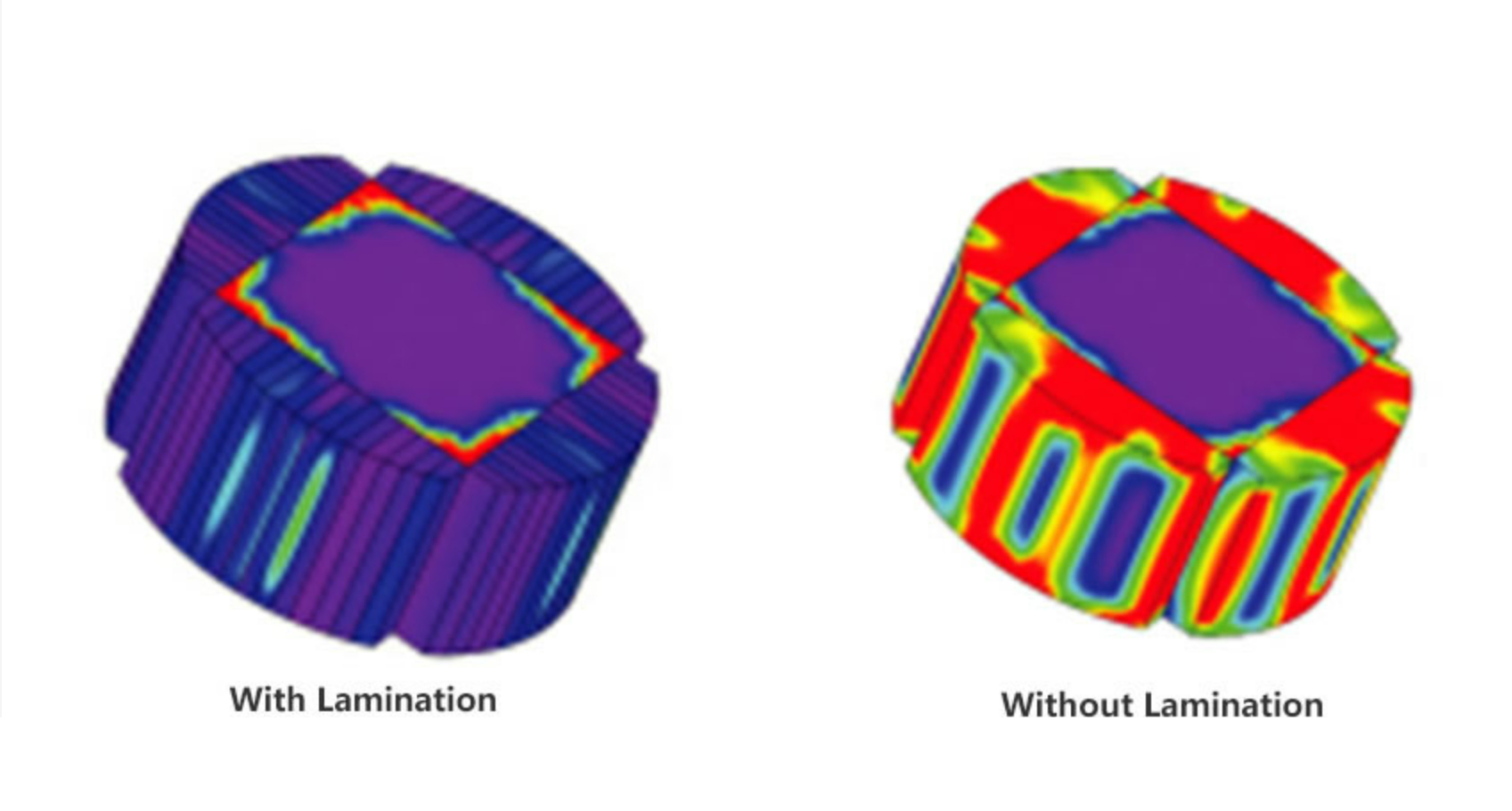

Eddy current is one of the biggest difficulties in the motor industry which will give rise to the temperature of permanent magnets and caused demagnetization, then affected the working efficiency of the motor.

In most cases, the eddy current loss of permanent magnets is much lower than iron loss and copper loss of the motor, but it will generate a large temperature rise in the high-speed motor and the high power density motor.

Ideally, stator magnetic field and rotor magnetic field of PMSM are rotating synchronously, or relatively static, thus permanent magnets without eddy current loss in such case. In fact, there are a series of space and time harmonics are existing in the air gap magnetic field, and these harmonic components are stemming from cogging effect, non-sinusoidal distribution of magnetomotive force and phase current. The harmonic magnetic field will link with rotor magnetic field and hence generated eddy current and caused relevant eddy current loss. It should be also noted that the harmonic magnetic field and eddy current loss will rise with increasing motor speed.

Laminated magnet is regarded as a wise solution to solve the eddy current loss in the surge of high-speed rotating machinery development.

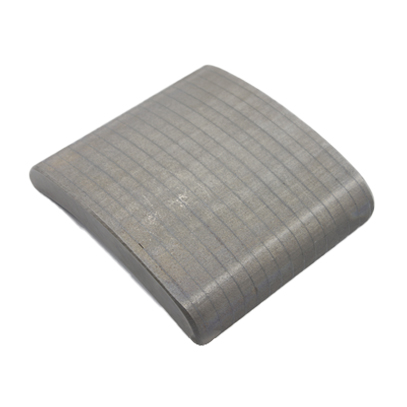

Laminated Neodymium Magnet to divide a whole piece of magnet into several pieces, and use special technology to bond these pieces into the whole magnet again with a certain glue in order to reduce eddy current loss. Fewer eddy current losses means lower heat and greater efficiency. The reduce of the eddy current loss can decrease the heat and enhance the efficiency.

Laminated magnets have small eddy current and have the same or even superior performance as the overall magnets. Therefore, More and more laminated magnets are applied to motors, especially electric vehicles motors. Nowadays, new-energy Auto, aerospace as well as Intelligent industrial robot markets are addicted to pursuing the balance of motor power and calorific value, so the demand of laminated neodymium magnet has kept increasing. With respect to your designing team and project requirement, we can help you to realize the magnetic customization of the following contents by using the licensed process and our production capacity.

-Excellent superficial magnetic force consistency;

-The unique production method has competitive advantages in production efficiency, product manufacturing accuracy and cost control.

-This magnet has excellent resistance to high temperature and humidity of the anti-corrosion properties because of using overall plating surface protection technology;

-By means of insulated stitching, these small magnets are insulated from each other;

-The thickness of insulating layers is within 0.04mm;

-The bond strength of insulating layers can reach more than 50Mpa at room temperature;

-The maximum working temperature is up to 200 ℃;

-The geometric tolerance for laminated magnet is within±05mm;

-They are available in samarium cobalt and neodymium iron boron materials;

-Custom size and shapes acceptable too.

Calculation of eddy current losses with and without lamination are shown as below :