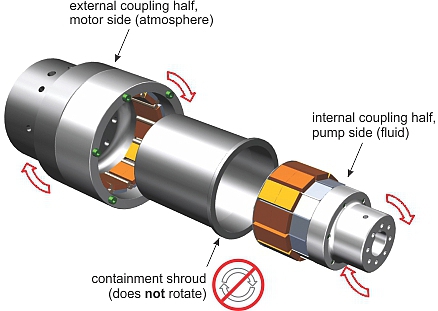

Magnetic couplings are non-contact couplings that use a magnetic field to transfer torque, force or movement from one rotating member to another. The transfer takes place through a non-magnetic containment barrier without any physical connection. The couplings are opposing pairs of discs or rotors embedded with magnets.

The use of magnetic coupling dates back to successful experiments by Nikola Tesla in the late 19th century. Tesla wirelessly lit lamps using near-field resonant inductive coupling. Scottish physicist and engineer Sir Alfred Ewing further advanced the theory of magnetic induction in the early 20th century. This led to the development of a number of technologies using magnetic coupling. Magnetic couplings in applications that require highly precise and more robust operation have taken place in the last half-century. The maturity of advanced manufacturing processes and the increased availability of rare earth magnetic materials makes this possible.

While all magnetic couplings use the same magnetic properties and basic mechanical forces, there are two types that differ by design.

The two main types include:

-Disc-type couplings featuring two face-to-face disc halves embedded with a series of magnets where torque is transferred across the gap from one disc to the other

-Synchronous-type couplings such as permanent magnet couplings, coaxial couplings and rotor couplings where an internal rotor is nested inside of an external rotor and permanent magnets transfer torque from one rotor to the other。

In addition to the two main types, magnetic couplings includes spherical, eccentric, spiral and nonlinear designs. These magnetic coupling alternatives aid in the use of torque and vibration, specifically used in applications for biology, chemistry, quantum mechanics, and hydraulics.

In the simplest terms, magnetic couplings work using the fundamental concept that opposite magnetic poles attract. The attraction of the magnets transmits torque from one magnetized hub to another (from the driving member of the coupling to the driven member). Torque describes the force that rotates an object. As external angular momentum is applied to one magnetic hub, it drives the other by transmitting torque magnetically between the spaces or through a non-magnetic containment barrier such as a dividing wall.

The amount of torque generated by this process is determined by variables such as:

-Working temperature

-Environment in which processing occurs

-Magnetic polarization

-Number of pole pairs

-Dimensions of pole pairs, including gap, diameter and height

-Relative angular offset of the pairs

-Shift of the pairs

Depending on the alignment of the magnets and discs or rotors, the magnetic polarization is radial, tangential or axial. Torque is then transferred to one or more moving parts.

Magnetic couplings are considered superior to traditional mechanical couplings in several ways.

The lack of contact with moving parts:

-Reduces friction

-Produces less heat

-Makes maximum use of power produced

-Results in less wear and tear

-Produces no noise

-Eliminates the need for lubrication

Additionally, the enclosed design associated with particular synchronous types allows magnetic couplings to be manufactured as dust-proof, fluid-proof and rust-proof. The devices are corrosion resistant and engineered to handle extreme operating environments. Another benefit is a magnetic breakaway feature that establishes compatibility for use in areas with potential impact hazards. In addition, devices using magnetic couplings are more cost-effective than mechanical couplings when located in areas with limited access. Magnetic couplings are a popular choice for testing purposes and temporary installation.

Magnetic couplings are highly efficient and effective for numerous above-ground applications including:

-Robotics

-Chemical engineering

-Medical instruments

-Machine installation

-Food processing

-Rotary machines

Currently, magnetic couplings are prized for their effectiveness when submerged in water. Motors encased in a non-magnetic barrier within liquid pumps and propeller systems allow the magnetic force to operate the propeller or parts of the pump in contact with liquid. Water shaft failure caused by the invasion of water in a motor housing is avoided by spinning a set of magnets in a sealed container.

Underwater applications include:

-Diver propulsion vehicles

-Aquarium pumps

-Remotely operated underwater vehicles

As the technology improves, magnetic couplings become more prevalent as replacements for variable speed drives in pumps and fan motors. An example of significant industrial use is motors within large wind turbines.

The number, size and type of magnets used in a coupling system as well as the corresponding torque produced are significant specifications.

Other specifications include:

-The presence of a barrier between the magnetic pairs, qualifying the apparatus for submersion in water

-The magnetic polarization

-The number of moving parts torque is transferred magnetically

The magnets used in magnetic couplings compose of rare earth materials such as neodymium iron boron or samarium cobalt. Barriers that exist between the magnetic pairs are made of non-magnetic materials. Examples of materials that are not attracted by magnets are stainless steel, titanium, plastic, glass and fiberglass. The remainder of the components attached to either side of the magnetic couplings is identical to those used in any system with traditional mechanical couplings.

The correct magnetic coupling must meet the required level of torque specified for the intended operation. In the past, the strength of the magnets was a limiting factor. However, the discovery and increased availability of special rare earth magnets is rapidly growing capabilities of magnetic couplings.

A second consideration is the necessity of the couplings to be partially or entirely submerged in water or other forms of liquid. Magnetic coupling manufacturers provide customization services for unique and concentrated needs.