With the progress of society, high buildings have become the mainstream of urban development in the world, and elevators have also become the necessary means of transportation for daily life. In elevators, traction machine is the heart of the elevator, and its operation is related to people’s life safety. The performance of Nd-Fe-B as the core component greatly affects the stability and safety of elevator operation.

China is the largest elevator manufacturer, consumer and exporter. China Elevator Association calculates that the energy consumption of elevators reaches 5% of the energy consumption of the whole building, which means that elevators are one of the largest energy consuming equipment in high-rise buildings.

Permanent magnet synchronous traction machine has occupied the mainstream of the market. At present, it is the absolute option of elevator drive motor. Therefore, the demand for elevator traction machine magnet has been very huge.

The traction machine elevator is mainly composed of traction system, guiding system, gate system, car, weight balance system, electric drive system, power control system and safety protection system. The traction machine outputs and transmits power to drive the elevator to operate normally.

The traction machine is composed of motor, brake, coupling, reduction gearbox, traction wheel, frame and guide wheel. Traction machine can be divided into DC traction machine and AC traction machine according to motor type, while AC traction machine can be divided into AC gear traction machine, AC gearless traction machine and permanent magnet traction machine. Permanent magnet gearless traction machine is widely used in elevator industry because of its small volume, stable operation at low speed, no maintenance, low energy consumption and low noise.

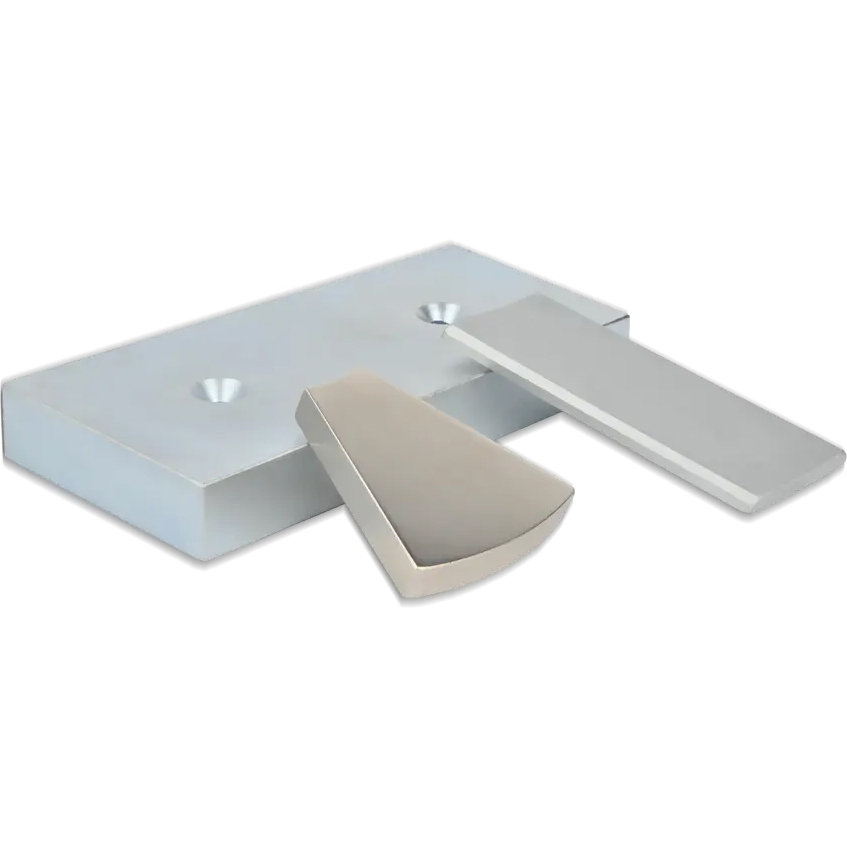

High performance rare earth neodymium magnet is one of the core components of elevator traction machine. As the excitation source of traction machine, the irreversible magnetic flux loss of magnet will bring potential safety hazards to the whole elevator system.

Elevator traction machine magnets generally use n35sh, n38sh, n40sh and n33uh high-performance neodymium iron boron. In a specific historical period, the explosive growth of elevator traction machine has promoted the development of high coercivity sintered neodymium iron boron magnets to a certain extent.

Honsen Magnetics strictly controls the quality based on the values of the company “quality first and safety first”! Our goal is to make each product traceable and lay a solid foundation for people’s travel comfort and safety.