Last time we talked about what are NdFeB magnets.But many people are still confused about what are NdFeB magnets. This time I will explain what are NdFeB magnets from the following perspectives.

1.Are neodymium magnets pure neodymium?

2.What are neodymium magnets?

3.What is the life of neodymium magnets?

4.What are some cool things I can do with neodymium magnets?

5.Why are neodymium magnets so strong?

6.Why are neodymium magnets expensive?

7.How to clean neodymium magnet spheres?

8.How to find the grade of a neodymium magnet?

9.Is there a limit to how large a neodymium magnet can be?

0.Is neodymium strongly magnetic in its pure form?

Let's get started

6.Why are neodymium magnets expensive?

Neodymium magnets are relatively expensive compared to other types of magnets due to a few factors:

Rare earth materials: Neodymium is one of the rare earth elements, which are not commonly found in the earth's crust. Mining and processing these materials can be expensive, and the limited supply of these materials can drive up the cost.

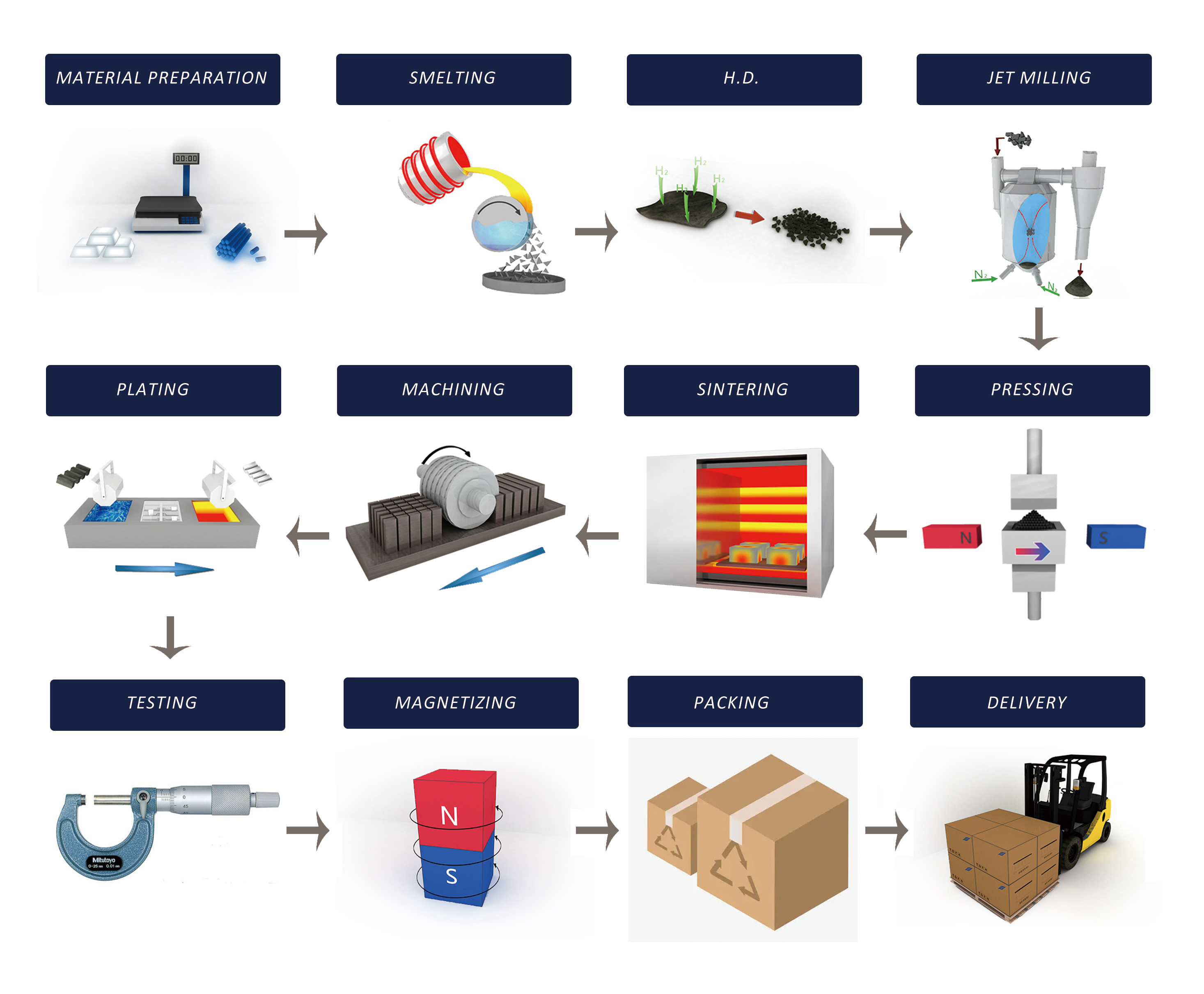

Manufacturing process: The production process for neodymium magnets is complex and involves multiple steps, including alloying the raw materials, milling, pressing, and sintering. These processes require specialized equipment and expertise, which can add to the cost.

High demand: Neodymium magnets are in high demand due to their unique properties, such as their strength and small size. This high demand can drive up the price, especially during times of supply chain disruptions or increased global demand.

NdFeB production flow

7.How to clean neodymium magnet spheres?

To clean neodymium magnet spheres, you can follow these simple steps:

1.Mix a small amount of mild dish soap with warm water in a bowl or sink.

2.Place the neodymium magnet spheres into the soapy water and let them soak for a few minutes.

3.Gently scrub the surface of the spheres with a soft-bristled brush or cloth to remove any dirt or debris.

4.Rinse the spheres thoroughly with clean water to remove any soap residue.

5.Dry the spheres with a clean, soft cloth.

Note: Do not use any harsh chemicals or abrasive materials to clean neodymium magnet spheres, as this can damage the surface of the spheres and affect their magnetic properties. Additionally, be sure to handle neodymium magnets carefully, as they are brittle and can easily crack or break if dropped or mishandled.

8.How to find the grade of a neodymium magnet?

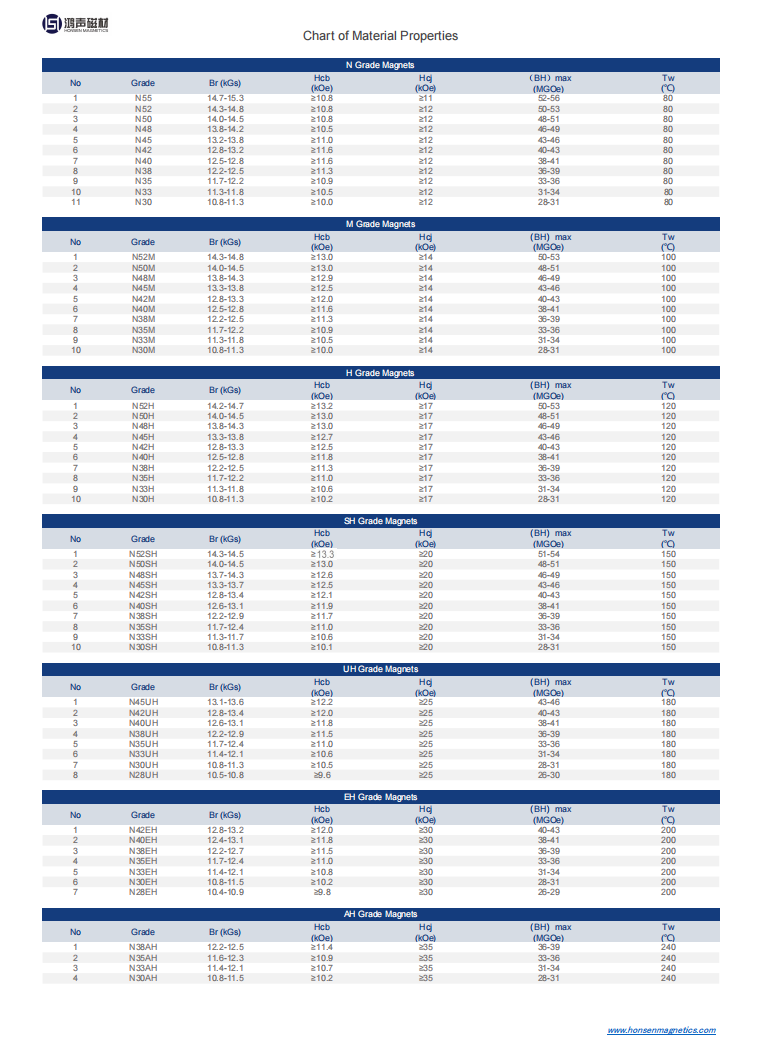

To find the grade of a neodymium magnet, you can usually find a code printed or stamped on the magnet itself. This code typically consists of a combination of numbers and letters that indicate the strength and composition of the magnet. Here are the steps to find the grade of a neodymium magnet:

Look for a code on the magnet. This code is usually printed or stamped on one of the flat surfaces of the magnet.

The code will typically consist of a series of letters and numbers, such as "N52" or "N35EH".

The first letter or letters indicate the material composition of the magnet. For example, "N" stands for neodymium, while "Sm" stands for samarium cobalt.

The number that follows the first letter or letters indicates the maximum energy product of the magnet, which is a measure of its strength. The higher the number, the stronger the magnet.

Sometimes there will be additional letters or numbers at the end of the code, which can indicate other properties of the magnet, such as its temperature resistance or shape.

If there is no way to find out the grade of the neodymium magnet you can also find out by means of a test. This is because the grade of a neodymium magnet is differentiated by the performance of the neodymium magnet. You can use a gauss meter to measure the surface magnetism of a neodymium magnet and then use the table to determine the grade of a neodymium magnet.

9.Is there a limit to how large a neodymium magnet can be?

There is no hard limit to how large a neodymium magnet can be, but there are practical limits that are determined by a few factors.

One factor is the availability of the rare earth materials used to make neodymium magnets. These materials are not commonly found in the earth's crust and are expensive to mine and process. As the size of the magnet increases, so does the amount of material needed, which can make larger magnets prohibitively expensive.

Another factor is the manufacturing process. The production of neodymium magnets involves several steps, including alloying the raw materials, milling, pressing, and sintering. These processes require specialized equipment and expertise, which can be more difficult and expensive to scale up for larger magnets.

Neodymium magnets can also be produced in very large

Additionally, larger neodymium magnets can be more difficult to handle and pose safety risks due to their strong magnetic fields. They can also be more prone to breaking or cracking due to their brittleness.

The neodymium magnets are made from a mixture of neodymium, iron and boron powders, which means that the distribution of neodymium in neodymium magnets is not completely uniform, and it is difficult to ensure that the magnetism of a neodymium magnet is of the same strength everywhere. As a result, larger neodymium magnets are often very expensive to ensure superior performance.

0.Is neodymium strongly magnetic in its pure form?

Neodymium by itself is not strongly magnetic, as it is a rare-earth metal with a paramagnetic property, meaning it is weakly attracted to magnetic fields. However, when neodymium is combined with other elements such as iron and boron to create the alloy Nd2Fe14B, which is used in the production of neodymium magnets, the resulting compound exhibits very strong magnetic properties due to the alignment of its atomic magnetic moments. The neodymium in the alloy plays a key role in contributing to the strong magnetic field strength of neodymium magnets.

A good example of this is the pot magnet. The pot magnet consists of three parts: a plastic positioning ring, an iron housing and a neodymium magnet. The main function of the plastic ring is to fix the neodymium magnet, so it is possible to do without the plastic positioning ring to save costs according to the customer's requirements. The main reason why the pot magnet has an iron casing is for two reasons: 1. the neodymium magnet is fragile and the iron casing can protect it to a certain extent and increase the life of the pot magnet; 2. the neodymium magnet and the iron casing together can produce stronger magnetism.

Tips: Don't underestimate such a small pot magnet, it is more magnetic than you can imagine.

Post time: Mar-16-2023