What is NdFeB Magnets

According to production processes, Neodymium Magnets can be divided into Sintered Neodymium and Bonded Neodymium. Bonded Neodymium has magnetism in all directions and is corrosion resistant; Sintered Neodymium is prone to corrosion and requires coating on its surface, generally including zinc plating, nickel plating, environmentally friendly zinc plating, environmentally friendly nickel plating, nickel copper nickel plating, environmentally friendly nickel copper nickel plating, etc.

Classification of Neodymium Magnets

Depending on the manufacturing method employed, Neodymium Magnet materials can be divided into Sintered Neodymium and Bonded Neodymium. Bonded Neodymium has magnetism in all directions and is corrosion resistant; Sintered Neodymium is prone to corrosion and requires coating on its surface, generally including zinc plating, nickel plating, environmentally friendly zinc plating, environmentally friendly nickel plating, nickel copper nickel plating, environmentally friendly nickel copper nickel plating, etc. In many applications in contemporary goods that need powerful permanent magnets, such as electric motors in cordless tools, hard disk drives, and magnetic fasteners, they have taken the place of other types of magnets.

The most common kind of Rare-Earth Magnet is a Neodymium Magnet, commonly referred to as a NdFeB, NIB, or Neo magnet. Neodymium, Iron, and Boron were combined to create the Permanent Magnet's Nd2Fe14B tetragonal crystalline structure. Neodymium Magnets are the strongest type of Permanent Magnet currently on the market. They were separately developed in 1984 by General Motors and Sumitomo Special Metals.

Neodymium Magnet is a relatively hard brittle material with low density but high mechanical properties, and its production cost is lower than other Rare Earth Permanent Magnet Materials. At present, based on the horizontal comparison of market share with third-generation Rare Earth Permanent Magnet Materials, Neodymium Magnets have the highest market share and annual production, only lower than cheaper Ferrite Magnets.

Sintered NdFeB magnets have the highest magnetic qualities and are used in a number of sectors, including door latches, motors, generators, and heavy industrial components.

Bonded compressed magnets are stronger than injection molded magnets.

Injection Plastic NdFeB magnet is a new-generation composite material comprised of permanent magnetic powder and plastic, with extraordinary magnetic and plastic qualities, as well as high accuracy and stress resistance.

Sintered Neodymium Magnets

Sintered Neodymium Magnet is a contemporary strong magnet, which not only has excellent characteristics such as high remanence, high coercivity, high magnetic energy product, and high-performance price ratio but also is easy to process into various shapes and sizes, especially suitable for high-power and high magnetic field fields, as well as various miniaturized and lightweight replacement products.

Sintered Neodymium Magnets are mainly used in automobiles (electric drive, electric power steering, sensors, etc.), wind power generation, the information industry (hard disk drives, optical disk drives), consumer electronics (mobile phones, digital cameras), household appliances (variable frequency air conditioning, refrigerators, and washing machines), elevator linear motors, nuclear magnetic resonance imaging machines, etc. In intelligent manufacturing, intelligent driving, represented by robots Applications in areas such as intelligent services are on the rise.

Bonded Neodymium Magnets

Bonded Neodymium Magnet is a type of composite permanent magnet material made by combining rapidly quenched nanocrystalline neodymium iron boron magnetic powder with high polymer (such as thermosetting epoxy resin, thermoplastic engineering plastics, etc.) as a binder, divided into Bonded Neodymium Compressed Magnets and Bonded Neodymium Injection Magnets. It has extremely high dimensional accuracy, good magnetic uniformity, and consistency, and can be made into complex shapes that are difficult to achieve on sintered neodymium magnets and is easy to integrate with other metal or plastic components for forming. Bonded Neodymium Magnets also have various magnetization methods, low eddy current loss, and strong corrosion resistance.

Bonded Neodymium Magnets are mainly used in information technology industries such as computer hard drives and optical disc drive spindle motors, printer/copier motors, and magnetic rollers, as well as drive and control components for variable frequency energy-saving household appliances and consumer electronics. Their application in micro and special motors and sensors of new energy vehicles is gradually becoming an emerging mainstream market.

Explanation of Strength

Neodymium is an antiferromagnetic metal that exhibits magnetic characteristics when it is pure, but only at temperatures below 19 K (254.2 °C; 425.5 °F). Neodymium compounds with ferromagnetic transition metals like iron, having Curie temperatures much above room temperature, are used to create neodymium magnets.

Neodymium magnets' strength is a combination of various things. The most significant is the extremely high uniaxial magnetocrystalline anisotropy of the tetragonal Nd2Fe14B crystal structure (HA 7 T - magnetic field strength H in units of A/m against magnetic moment in Am2). This indicates that a crystal of the substance magnetizes preferentially along a certain crystal axis but finds it extremely challenging to magnetize in other directions. The neodymium magnet alloy, like other magnets, is made of microcrystalline grains that are during manufacturing aligned in a strong magnetic field such that their magnetic axes all point in the same direction. The compound has an extremely high coercivity, or resistance to demagnetization, due to the crystal lattice's resistance to changing its direction of magnetism.

Because it contains four unpaired electrons in its electron structure as compared to (on average) three in iron, the neodymium atom is able to have a significant magnetic dipole moment. The unpaired electrons in a magnet that are aligned so that their spins are facing the same direction produce the magnetic field. This results in a strong saturation magnetization for the Nd2Fe14B combination (Js 1.6 T or 16 kG) and a typical residual magnetization of 1.3 teslas. As a result, this magnetic phase has the capacity to store significant amounts of magnetic energy (BHmax 512 kJ/m3 or 64 MGOe), as the highest energy density is proportional to Js2.

This magnetic energy value is around 18 times by volume and 12 times by mass larger than "regular" ferrite magnets. Samarium cobalt (SmCo), the first commercially available rare-earth magnet, has a lower level of this magnetic energy feature than NdFeB alloys. Neodymium magnets' magnetic characteristics are really influenced by the alloy's microstructure, manufacturing process, and composition.

Iron atoms and a neodymium-boron combination are found in alternate layers inside the Nd2Fe14B crystal structure. The diamagnetic boron atoms promote cohesion through strong covalent bonds but do not directly contribute to magnetism. Neodymium magnets are less expensive than samarium-cobalt magnets due to the comparatively low rare earth concentration (12% by volume, 26.7% by mass), as well as the relative availability of neodymium and iron compared to samarium and cobalt.

Properties

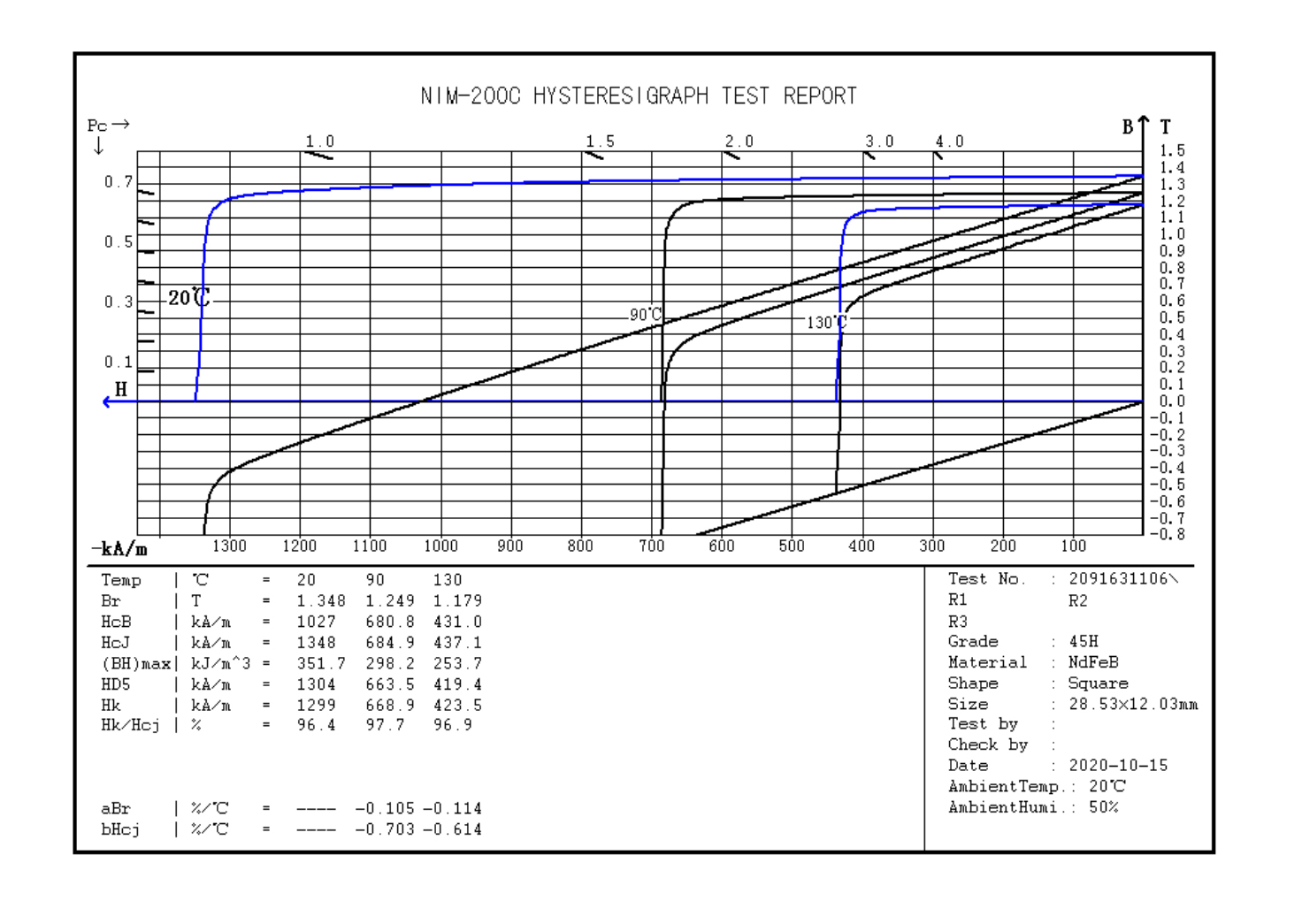

Grades:

The maximal energy product of neodymium magnets—which corresponds to the magnetic flux production per unit volume—is used to classify them. Stronger magnets are indicated by higher values. There is a generally accepted worldwide categorization for sintered NdFeB magnets. They range in value from 28 to 52. Neodymium, or sintered NdFeB magnets, is denoted by the initial N before the values. The values are followed by letters that denote intrinsic coercivity and maximum operating temperatures, which are correlated positively with the Curie temperature and range from the default (up to 80 °C or 176 °F) to TH (230 °C or 446 °F).

Grades of sintered NdFeB magnets:

N30-N56, N30M-N52M, N30H-N52H, N30SH-N52SH, N28UH-N45UH, N28EH-N42EH, N30AH-N38AH

Among the important characteristics used to contrast permanent magnets are:

Remanence (Br), which quantifies the magnetic field's strength.

Coercivity (Hci), demagnetization resistance of the material.

Maximum energy product (BHmax), the greatest value of magnetic flux density(B) times

magnetic field strength, which measures the density of magnetic energy (H).

Curie temperature (TC), the point at which a substance ceases to be magnetic.

Neodymium magnets outperform other types of magnets in terms of remanence, coercivity, and energy product, but frequently have lower Curie temperatures. Terbium and dysprosium are two special neodymium magnet alloys that have been created with higher Curie temperatures and higher temperature tolerance. Neodymium magnets' magnetic performance is contrasted with that of other permanent magnet types in the table below.

| Magnet | Br (T) | Hcj (kA/m) | BHmax kJ/m3 | TC | |

| ( ℃) | ( ℉) | ||||

| Nd2Fe14B, sintered | 1.0-1.4 | 750-2000 | 200-440 | 310-400 | 590-752 |

| Nd2Fe14B, bonded | 0.6-0.7 | 600-1200 | 60-100 | 310-400 | 590-752 |

| SmCo5, sintered | 0.8-1.1 | 600-2000 | 120-200 | 720 | 1328 |

| Sm(Co, Fe, Cu, Zr)7 sintered | 0.9-1.15 | 450-1300 | 150-240 | 800 | 1472 |

| AlNiCi, sintered | 0.6-1.4 | 275 | 10-88 | 700-860 | 1292-1580 |

| Sr-Ferrite, sintered | 0.2-0.78 | 100-300 | 10-40 | 450 | 842 |

Corrosion Problems

The grain boundaries of a sintered magnet are particularly susceptible to corrosion in sintered Nd2Fe14B. This kind of corrosion can result in significant damage, such as the spalling of a surface layer or the crumbling of a magnet into a powder of tiny magnetic particles.

Many commercial goods address this risk by including a protective covering to stop exposure to the environment. The most common platings are nickel, nickel-copper-nickel, and zinc, while other metals can also be used, as can polymer and lacquer protective coatings.

Temperature Effects

Neodymium has a negative coefficient, which means that when the temperature rises, both the coercivity and the maximum magnetic energy density (BHmax) drop. At ambient temperature, neodymium-iron-boron magnets have a high coercivity; however, when the temperature increases over 100 °C (212 °F), the coercivity rapidly drops until it reaches the Curie temperature, which is around 320 °C or 608 °F. This decrease in coercivity restricts the magnet's effectiveness in high-temperature applications like wind turbines, hybrid motors, etc. To prevent the performance from falling due to temperature fluctuations, terbium (Tb) or dysprosium (Dy) are added, increasing the cost of the magnet.

Applications

Because its higher strength allows the use of smaller, lighter magnets for a given application, neodymium magnets have supplanted alnico and ferrite magnets in many of the countless applications in contemporary technology where strong permanent magnets are required. Here are several examples:

Head actuators for computer hard disks

Mechanical e-cigarette firing switches

Locks for doors

mobile phone speakers & autofocus actuators

Servomotors & Synchronous motors

Motors for lifting and compressors

Spindle and stepper motors

Hybrid and electric car drive motors

Electric generators for wind turbines (with permanent magnet excitation)

Retail media case decouplers

Powerful neodymium magnets are utilized in process industries to capture foreign bodies and safeguard products and processes.

The increased strength of Neodymium Magnets has inspired new uses such as magnetic jewelry clasps, children's magnetic building sets (and other neodymium magnet toys), and as part of the closing mechanism of current sport parachute equipment. They are the principal metal in the once popular desk-toy magnets known as "Buckyballs" and "Buckycubes," however Some stores in the United States have opted not to sell them due to child-safety concerns, and they have been prohibited in Canada for the same reason.

With the emergence of open magnetic resonance imaging (MRI) scanners used to view the body in radiology departments as an alternative to superconducting magnets, the strength and magnetic field homogeneity of neodymium magnets have also opened up new possibilities in the medical industry.

Neodymium Magnets are used to treat gastroesophageal reflux disease as a surgically implanted anti-reflux system, which is a band of magnets surgically implanted around the lower esophageal sphincter (GERD). They've also been implanted in the fingers to enable a sensory sense of magnetic fields, albeit this is an experimental operation that only biohackers and grinders are familiar with.

Why Choose Us

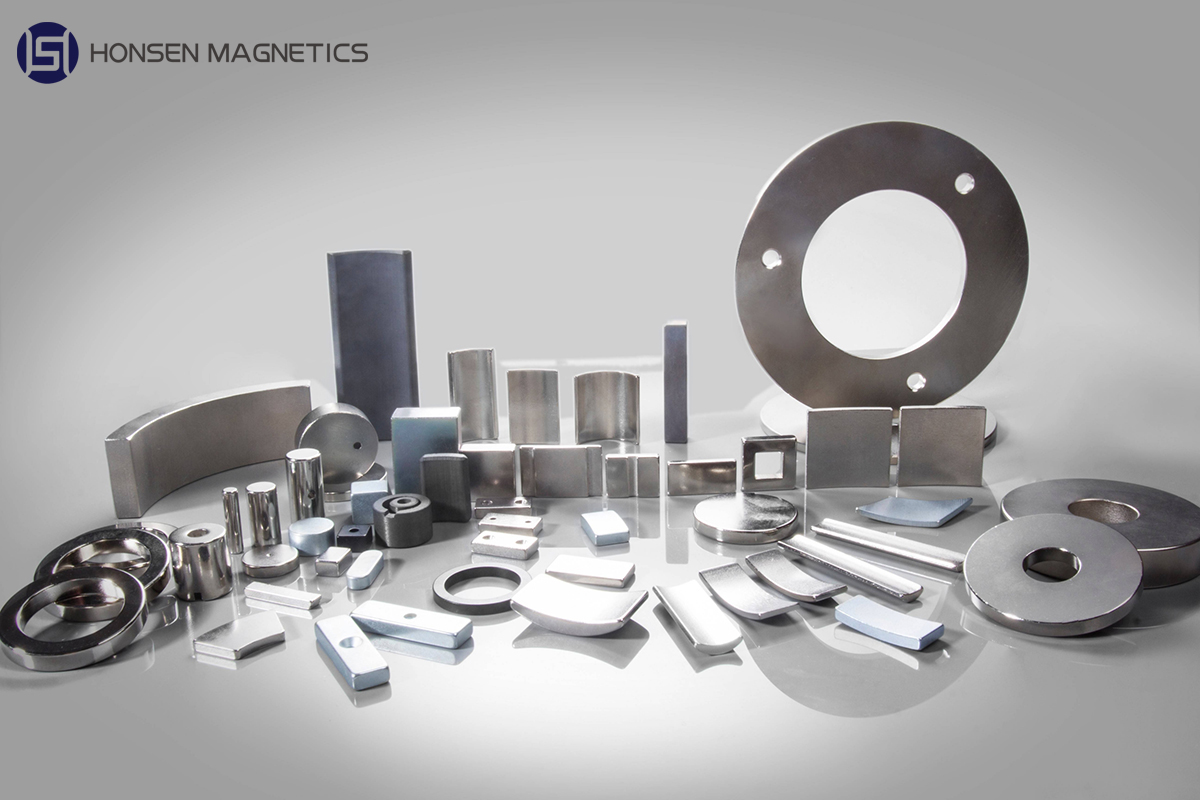

With over a decade of experience, Honsen Magnetics has consistently excelled in the manufacturing and trading of Permanent Magnets and Magnetic Assemblies. Our extensive production lines encompass various crucial processes such as machining, assembly, welding, and injection molding, which allows us to provide our customers with ONE-STOP-SOLUTION. These comprehensive capabilities allow us to produce top-notch products that meet the highest standards of quality.

At Honsen Magnetics, we take great pride in our customer-centric approach. Our philosophy revolves around putting the needs and satisfaction of our clients above everything else. This commitment ensures that we not only deliver exceptional products but also provide excellent service throughout the entire customer journey. Moreover, our exceptional reputation extends beyond borders. By consistently offering reasonable prices and maintaining superior product quality, we have gained immense popularity in Europe, America, Southeast Asia, and other countries. The positive feedback and trust we receive from our customers further solidify our standing in the industry.

Our Production Line

Quality Assurance

Our lovely Team & Customers

How we pack the goods