Ferrite magnets, also known as ceramic magnets, are created using ceramic processing technology from SrO or BaO and Fe203. This magnet requires specialized machining methods due to its extreme hardness and brittleness, but it has excellent corrosion resistance, a wide operating temperature range, and is inexpensive. The most common permanent magnets used today are ferrite magnets, which have a very wide range of uses, including toys, crafts, and loudspeakers as well as motors and other devices. Small circle ferrite magnets for crafts, hobbies, and advertising.

One of the magnets with numerous current applications is the ferrite magnet. Due to its low price, it is frequently used in microwave ovens, speakers, headphones, rotating motors, magnetic separators, DC motors, rotating motors, automotive motors (wiper, starter, fuel pump, seat motor, etc.), and other fields.

Advantages:

Simple manufacturing process;

Very good temperature stability;

Suitable for use between -40 and 200 °C;

Stony and fragile;

Ideally, avoid corrosion;

Since sintered ferrite magnets are oxide, they won't rust in harsh environments or be affected by a lot of chemicals (except some strong acids), widely utilized in a variety of applications, including those involving motors and speakers, and it is cuttable with diamond-tipped tools.

There are many ceramic disc magnets in our inventory that come in a variety of sizes; not all of them are displayed on this website. Check out Neodymium disc magnets if you require a very powerful magnet.

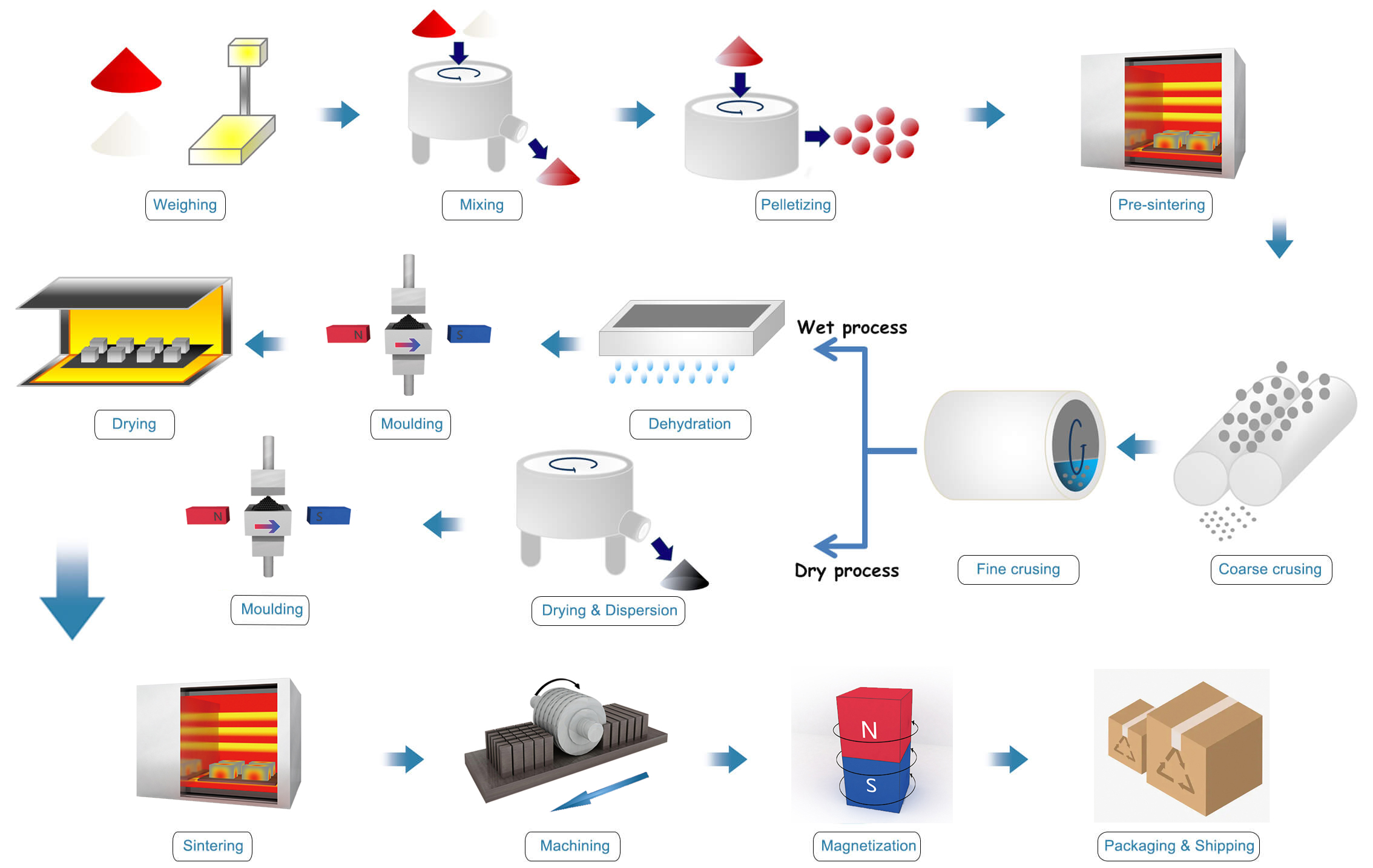

Manufacturing Process of Ferrite Magnets

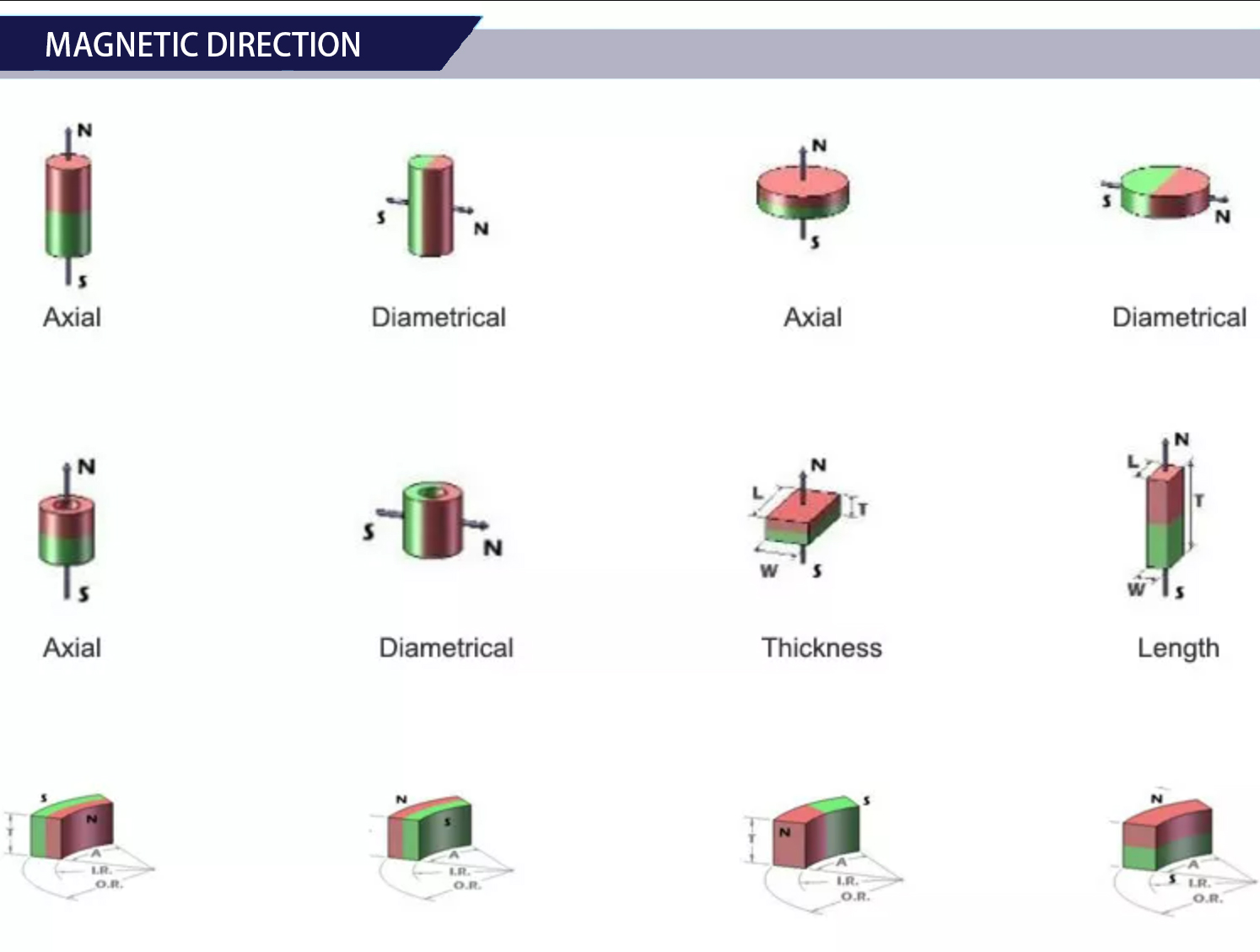

Magnetic Direction

Magnetic Properties

| Magnetic Properties of Ferrite Magnets | ||||||||

| Chinese Standard | ||||||||

| Grade | (Br) | (HcB) | (HcJ) | (BH)max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| Y10T | 200-235 | 2.0-2.35 | 125-160 | 1.57-2.01 | 210-280 | 2.64-3.52 | 6.5-9.5 | 0.8-1.2 |

| Y20 | 320-380 | 3.2-3.8 | 135-190 | 1.70-2.38 | 140-195 | 1.76-2.45 | 18.0-22.0 | 2.3-2.8 |

| Y22H | 310~360 | 3.10~3.60 | 220-250 | 2.77-3.14 | 280-320 | 3.52-4.02 | 20.0-24.0 | 2.5-3.2 |

| Y23 | 320-370 | 3.2-3.7 | 170-190 | 2.14-2.38 | 190-230 | 2.39-2.89 | 20.0-25.5 | 2.5-3.2 |

| Y25 | 360~400 | 3.60~4.00 | 135-170 | 1.70-2.14 | 140-200 | 1.76-2.51 | 22.5-28.0 | 2.8-3.5 |

| Y26H | 360-290 | 3.6-3.9 | 220-250 | 2.77-3.14 | 225-255 | 2.83-3.21 | 23.0-28.0 | 2.9-3.5 |

| Y27H | 370-400 | 3.7-4.0 | 225-250 | 2.58-3.14 | 210-255 | 2.64-3.21 | 25.0-29.0 | 3.1-3.7 |

| Y30 | 370-400 | 3.7-4.0 | 175-210 | 2.2-2.64 | 180-220 | 2.26-2.77 | 26.0-30.0 | 3.3-3.8 |

| Y30BH | 380-390 | 3.8-3.9 | 223-235 | 2.80-2.95 | 231-245 | 2.9-3.08 | 27.0-30.0 | 3.4-3.7 |

| Y30-1 | 380-400 | 3.8-4.0 | 230-275 | 2.89-3.46 | 235-290 | 2.95-3.65 | 27.0-32.0 | 3.4-4.0 |

| Y20-2 | 395-415 | 3.95-4.15 | 275-300 | 3.46-3.77 | 310-335 | 3.90-4.21 | 28.5-32.5 | 3.5-4.0 |

| Y32 | 400-420 | 4.0-4.2 | 160-190 | 2.01-2.38 | 165-195 | 2.07-2.45 | 30.0-33.5 | 3.8-4.2 |

| Y33 | 410-430 | 4.1-4.3 | 220-250 | 2.77-3.14 | 225-255 | 2.83-3.21 | 31.5-35.0 | 4.0-4.4 |

| Y35 | 400-410 | 4.0-4.1 | 175-195 | 2.20-2.45 | 180-200 | 2.26-2.51 | 30.0-32.0 | 3.8-4.0 |

| USA Standard | ||||||||

| Grade | (Br) | (HcB) | (HcJ) | (BH)max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| C1 | 230 | 2.3 | 148 | 1.86 | 258 | 3.5 | 8.36 | 1.05 |

| C5 | 380 | 3.8 | 191 | 2.4 | 199 | 2.5 | 27 | 3.4 |

| C7 | 340 | 3.4 | 258 | 3.23 | 318 | 4 | 21.9 | 2.75 |

| C8(=C8A) | 385 | 3.85 | 235 | 2.95 | 242 | 3.05 | 27.8 | 3.5 |

| C8B | 420 | 4.2 | 232 | 2.913 | 236 | 2.96 | 32.8 | 4.12 |

| C9 | 380 | 3.8 | 280 | 3.516 | 320 | 4.01 | 26.4 | 3.32 |

| C10 | 400 | 4 | 288 | 3.617 | 280 | 3.51 | 30.4 | 3.82 |

| C11 | 430 | 4.3 | 200 | 2.512 | 204 | 2.56 | 34.4 | 4.32 |

| European Standard | ||||||||

| Grade | (Br) | (HcB) | (HcJ) | (BH)max | ||||

| mT | KGauss | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | |

| HF8/22 | 200/220 | 2.00/2.20 | 125/140 | 1.57/1.76 | 220/230 | 2.76/2.89 | 6.5/6.8 | 0.8/1.1 |

| HF20/19 | 320/333 | 3.20/3.33 | 170/190 | 2.14/2.39 | 190/200 | 2.39/2.51 | 20.0/21.0 | 2.5/2.7 |

| HF20/28 | 310/325 | 3.10/3.25 | 220/230 | 2.76/2.89 | 280/290 | 3.52/3.64 | 20.0/21.0 | 2.5/2.7 |

| HF22/30 | 350/365 | 3.50/3.65 | 255/265 | 3.20/3.33 | 290/300 | 3.64/3.77 | 22.0/23.5 | 2.8/3.0 |

| HF24/16 | 350/365 | 3.50/3.65 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 24.0/25.5 | 3.0/3.2 |

| HF24/23 | 350/365 | 3.50/3.65 | 220/230 | 2.76/2.89 | 230/240 | 2.89/3.01 | 24.0/25.5 | 3.0/3.2 |

| HF24/35 | 360/370 | 3.60/3.70 | 260/270 | 3.27/3.39 | 350/360 | 4.40/4.52 | 24.0/25.5 | 3.0/3.2 |

| HF26/16 | 370/380 | 3.70/3.80 | 155/175 | 1.95/2.20 | 160/180 | 2.01/2.26 | 26.0/27.0 | 3.2/3.4 |

| HF26/18 | 370/380 | 3.70/3.80 | 175/190 | 2.20/2.39 | 180/190 | 2.26/2.39 | 26.0/27.0 | 3.2/3.4 |

| HF26/24 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 240/250 | 3.01/3.14 | 26.0/27.0 | 3.3/3.4 |

| HF26/26 | 370/380 | 3.70/3.80 | 230/240 | 2.89/3.01 | 260/270 | 3.27/3.39 | 26.0/27.0 | 3.3/3.4 |

| HF26/30 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 300/310 | 3.77/3.89 | 26.0/27.0 | 3.3/3.4 |

| HF28/26 | 385/395 | 3.85/3.95 | 250/265 | 3.14/3.33 | 260/275 | 3.27/3.45 | 28.0/30.0 | 3.5/3.8 |

| HF28/28 | 385/395 | 3.85/3.95 | 260/270 | 3.27/3.39 | 280/290 | 3.50/3.60 | 28.0/30.0 | 3.5/3.8 |

| HF30/26 | 395/405 | 3.95/4.05 | 250/260 | 3.14/3.33 | 260/270 | 3.27/3.39 | 30.0/31.5 | 3.8/3.9 |

| HF32/17 | 410/420 | 4.10/4.20 | 160/180 | 2.01/2.26 | 165/175 | 2.07/2.2 | 32.0/33.0 | 4.1/4.1 |

| HF32/22 | 410/420 | 4.10/4.20 | 215/225 | 2.70/2.83 | 220/230 | 2.76/2.89 | 32.0/33.0 | 4.1/4.1 |

| HF32/35 | 410/420 | 4.10/4.20 | 240/250 | 3.01/3.14 | 250/260 | 3.14/3.27 | 32.0/33.0 | 4.0/4.1 |

Applications

Why Honsen Magnetics

Our complete production line guarantees production capacity from raw materials to finished products

We serve ONE-STOP-SOLUTION to ensure customers efficient and cost-effective purchasing.

We test each piece of magnets to avoid any quality problem for customers.

We offer different types of packaging for customers to keep products & transportation safe.

We work with big customers as well as small ones without MOQ.

We offer all kinds of payment methods to facilitate customers' purchasing habits.