Magnets by Applications

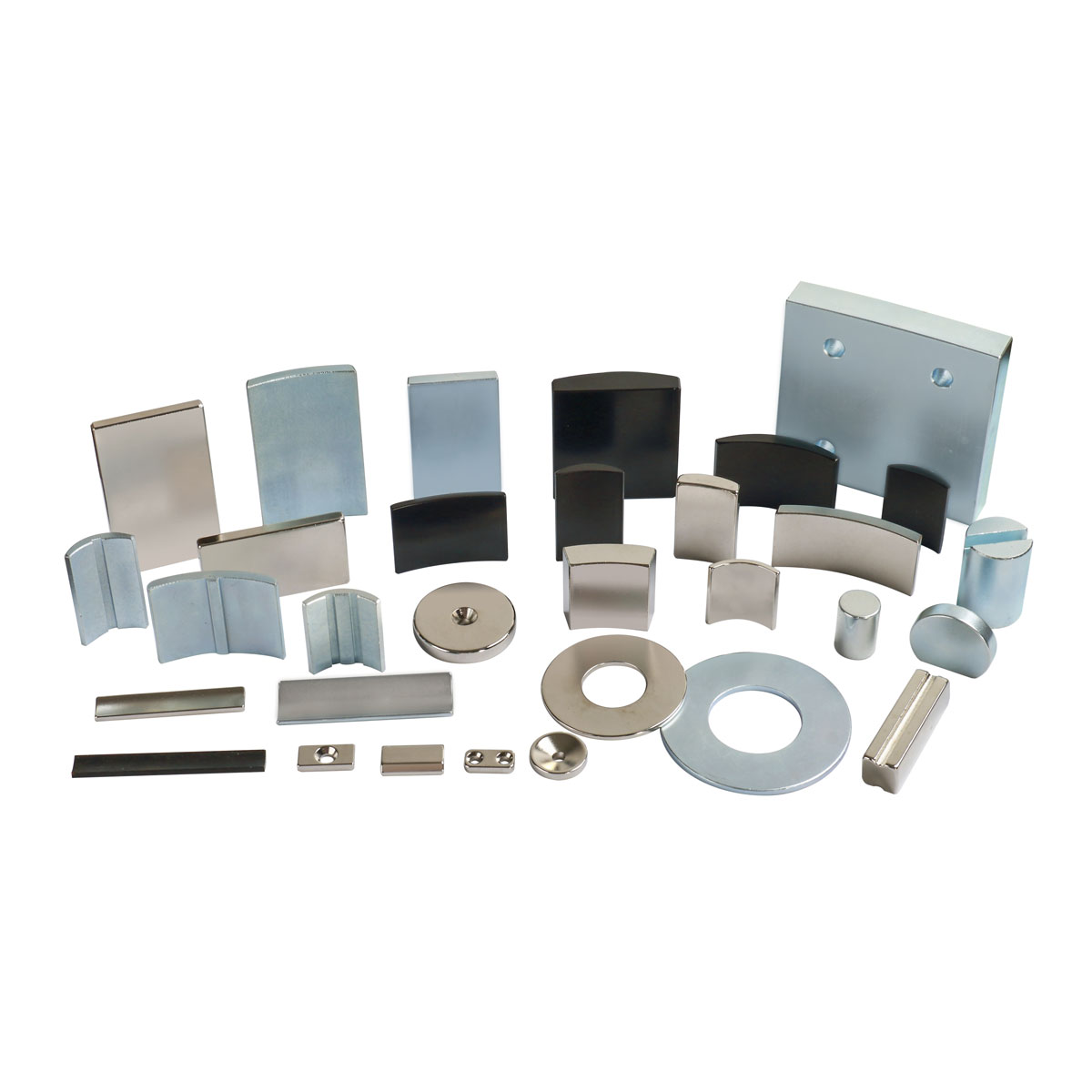

Magnetic materials from Honsen Magnetics have different applications in different industries. Neodymium iron boron magnets, also known as neodymium magnets, are the strongest type of permanent magnets available. They are widely used in electric motors, wind turbines, hard disk drives, loudspeakers and magnetic resonance imaging machines. Ferrite magnets, which are composed of iron oxide and ceramic materials. They are cost-effective and have good resistance to demagnetization. Due to their low cost and high magnetic stability, ferrite magnets find applications in motors, loudspeakers, magnetic separators, and magnetic resonance imaging (MRI) equipment. SMCo magnets or Samarium Cobalt magnets are known for their high corrosion resistance and high temperature stability. These magnets are commonly used in aerospace applications, industrial motors, sensors and magnetic couplings. In addition to the various magnet types, magnetic assemblies play a vital role in many applications. Magnetic components include products such as magnetic chucks, magnetic encoders and magnetic lifting systems. These components use magnets to create specific functions or enhance the performance of machines and equipment. Magnetic components are essential components in many electronic devices. They include items such as magnetic coils, transformers, and inductors. These components are used in power supplies, electric vehicles, telecommunications systems and other electronic equipment to control and manipulate magnetic fields.-

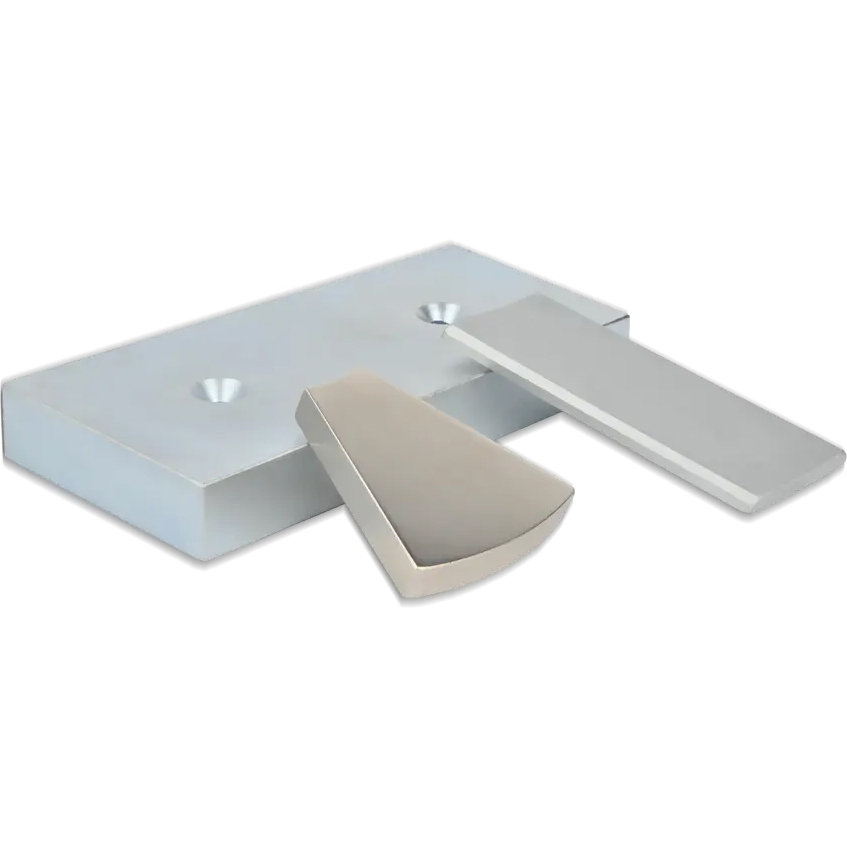

Elevator Traction Machine Magnets

Neodymium Iron Boron magnet, as the latest result of the development of rare earth permanent magnetic materials, is called “magneto king” because of its excellent magnetic properties. NdFeB magnets are alloys of neodymium and iron oxide. Also known as Neo Magnet. NdFeB has extremely high magnetic energy product and coercivity. At the same time, the advantages of high energy density makes NdFeB permanent magnets widely used in modern industry and electronic technology, which makes it possible to miniaturize, lightweight and thin instruments, electroacoustic motors, magnetic separation magnetization and other equipment.

-

Neodymium Magnets for Electronics & Electroacoustic

When the changing current is fed into the sound, the magnet becomes an electromagnet. The current direction changes constantly, and the electromagnet keeps moving back and forth due to the “force movement of the energized wire in the magnetic field”, driving the paper basin to vibrate back and forth. The stereo has sound.

The magnets on the horn mainly include ferrite magnet and NdFeB magnet. According to the application, NdFeB magnets are widely used in electronic products, such as hard disks, mobile phones, headphones and battery powered tools. The sound is loud.

-

Permanent Magnets for MRI & NMR

The large and important component of MRI & NMR is magnet. The unit that identifies this magnet grade is called Tesla. Another common unit of measurement applied to magnets is Gauss (1 Tesla = 10000 Gauss). At present, the magnets used for magnetic resonance imaging are in the range of 0.5 Tesla to 2.0 Tesla, that is, 5000 to 20000 Gauss.

-

Coatings & Platings Options of Permanent Magnets

Surface Treatment: Cr3+Zn, Color Zinc, NiCuNi, Black Nickel, Aluminium, Black Epoxy, NiCu+Epoxy, Aluminium+Epoxy, Phosphating, Passivation, Au, AG etc.

Coating Thickness: 5-40μm

Working Temperature: ≤250 ℃

PCT: ≥96-480h

SST: ≥12-720h

Please contact our expert for coating options!