Magnets by Applications

Magnetic materials from Honsen Magnetics have different applications in different industries. Neodymium iron boron magnets, also known as neodymium magnets, are the strongest type of permanent magnets available. They are widely used in electric motors, wind turbines, hard disk drives, loudspeakers and magnetic resonance imaging machines. Ferrite magnets, which are composed of iron oxide and ceramic materials. They are cost-effective and have good resistance to demagnetization. Due to their low cost and high magnetic stability, ferrite magnets find applications in motors, loudspeakers, magnetic separators, and magnetic resonance imaging (MRI) equipment. SMCo magnets or Samarium Cobalt magnets are known for their high corrosion resistance and high temperature stability. These magnets are commonly used in aerospace applications, industrial motors, sensors and magnetic couplings. In addition to the various magnet types, magnetic assemblies play a vital role in many applications. Magnetic components include products such as magnetic chucks, magnetic encoders and magnetic lifting systems. These components use magnets to create specific functions or enhance the performance of machines and equipment. Magnetic components are essential components in many electronic devices. They include items such as magnetic coils, transformers, and inductors. These components are used in power supplies, electric vehicles, telecommunications systems and other electronic equipment to control and manipulate magnetic fields.-

Permanent Magnetic Couplings for Drive Pump & magnetic mixers

Magnetic couplings are non-contact couplings that use a magnetic field to transfer torque, force or movement from one rotating member to another. The transfer takes place through a non-magnetic containment barrier without any physical connection. The couplings are opposing pairs of discs or rotors embedded with magnets.

-

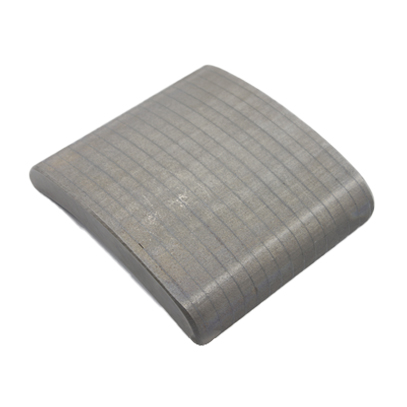

Laminated Permanent Magnets to reduce Eddy Current Loss

The purpose to cut a whole magnet into several pieces and apply the together is to reduce eddy loss. We call this kind magnets “Lamination”. Generally, the more pieces, the better the effect of eddy loss reduction. The lamination will not deteriorate the overall magnet performance, only the flux will slightly affected. Normally we control the glue gaps within a certain thickness using special method to control each gap has the same thickness.

-

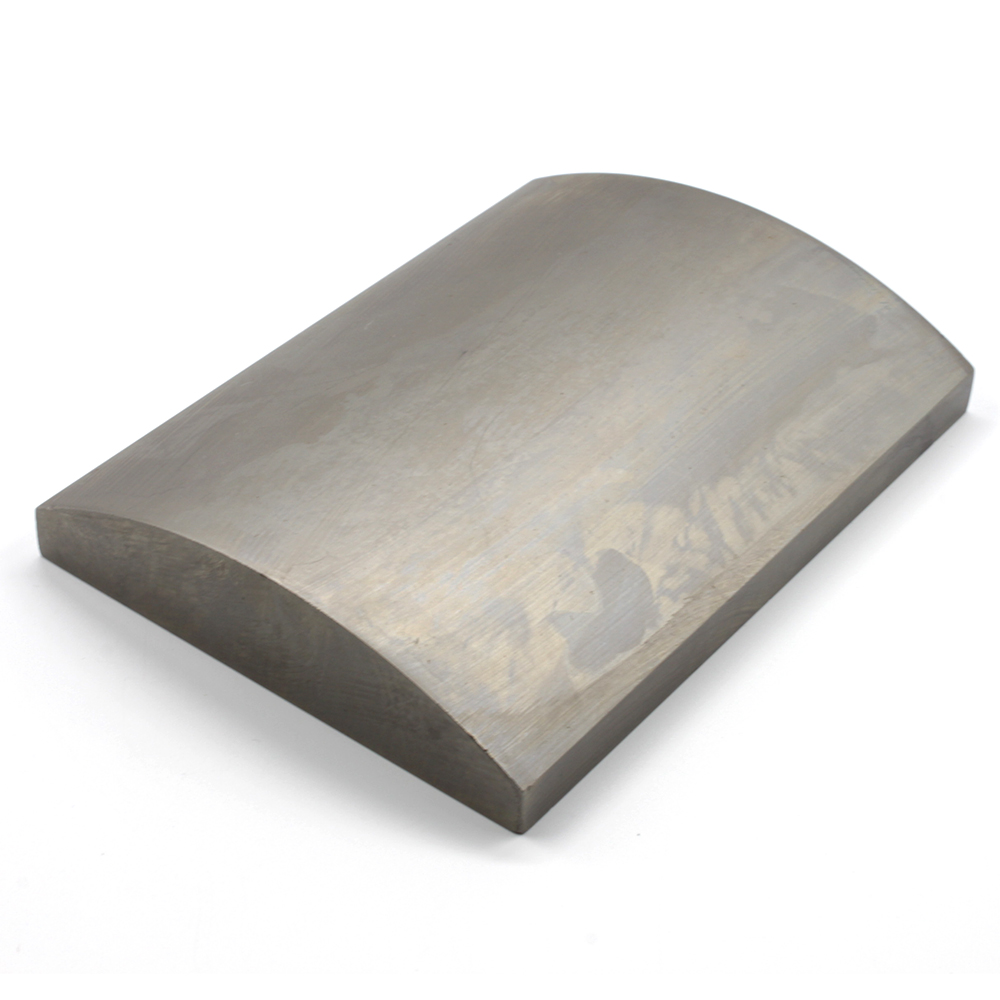

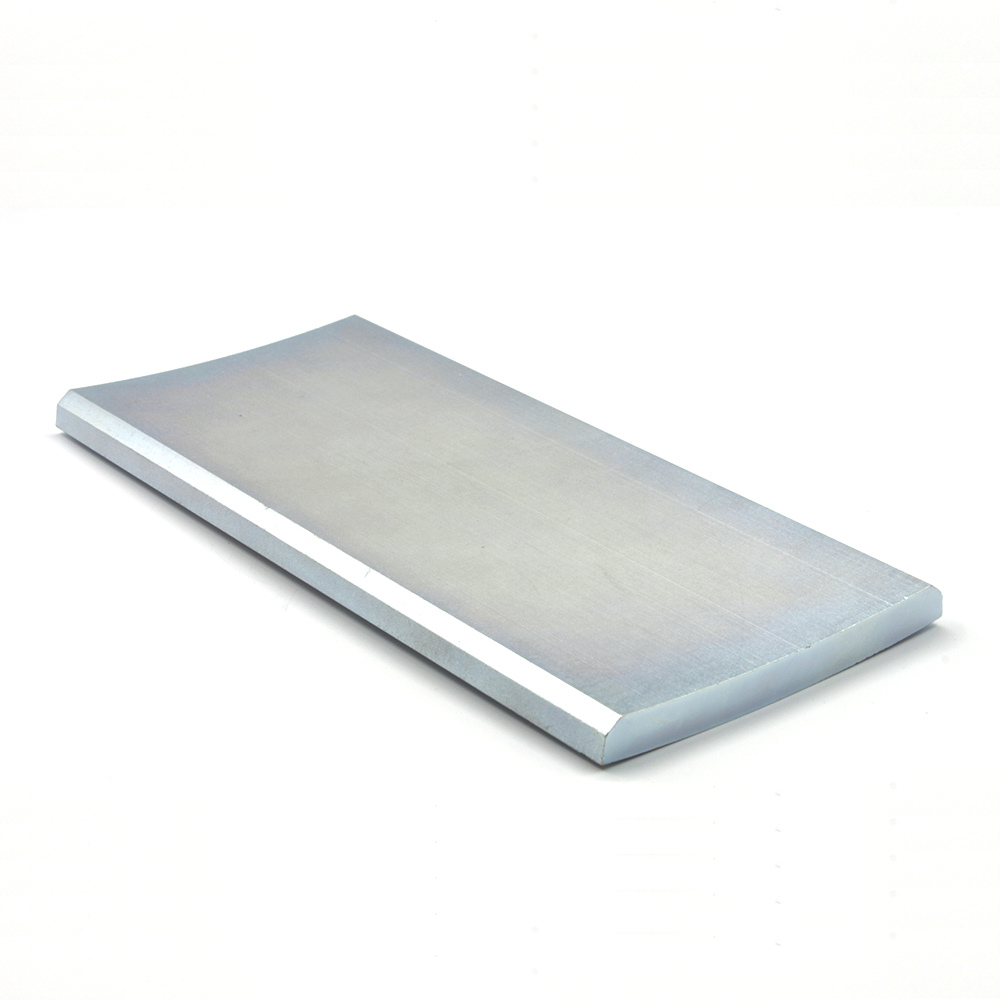

N38H Neodymium Magnets for Linear Motors

Product Name: Linear Motor Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Neodymium block magnet or customized -

Halbach Array Magnetic System

Halbach array is a magnet structure, which is an approximate ideal structure in engineering. The goal is to generate the strongest magnetic field with the smallest number of magnets. In 1979, when Klaus Halbach, an American scholar, conducted electron acceleration experiments, he found this special permanent magnet structure, gradually improved this structure, and finally formed the so-called “Halbach” magnet.

-

Magnetic Motor Assemblies with Permanent Magnets

Permanent magnet motor generally can be classified into permanent magnet alternating current (PMAC) motor and permanent magnet direct current (PMDC) motor according to current form. PMDC motor and PMAC motor can be further divided to brush/brushless motor and asynchronous/synchronous motor, respectively. Permanent magnet excitation can significantly decrease power consumption and strengthen the running performance of the motor.

-

Rare Earth Magnetic Rod & Applications

Magnetic rods are mainly used to filter iron pins in raw materials; Filter all kinds of fine powder and liquid, iron impurities in semi liquid and other magnetic substances. At present, it is widely used in chemical industry, food, waste recycling, carbon black and other fields.

-

Magnetic Tools & Equipment & Applications

Magnetic tools are tools that use electromagnetic technologies such as permanent magnets to assist the mechanical manufacturing process. They can be divided into magnetic fixtures, magnetic tools, magnetic molds, magnetic accessories and so on. Using magnetic tools greatly improve production efficiency and reduce the labor intensity of employees.

-

Permanent Magnets used in Automotive Industry

There are many different uses for permanent magnets in automotive applications, including efficiency. The automotive industry is focused on two kinds of efficiency: fuel-efficiency and efficiency on the production line. Magnets help with both.

-

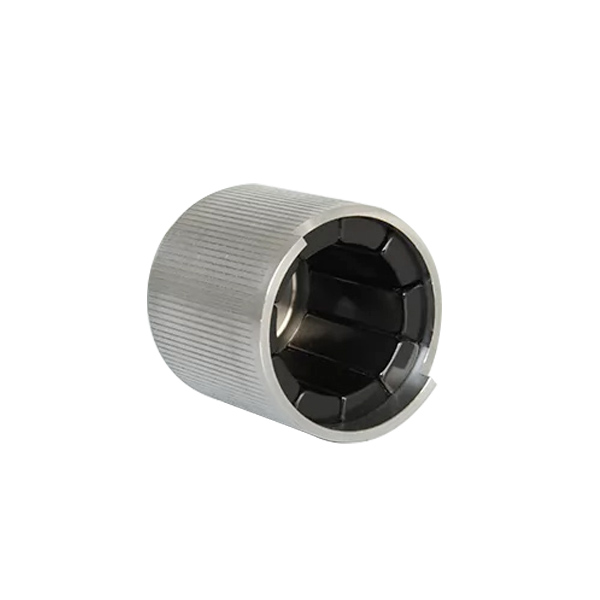

Servo Motor Magnets Manufacturer

The N pole and S pole of the magnet are arranged alternately. One N pole and one s pole are called a pair of poles, and the motors can have any pair of poles. Magnets are used including aluminum nickel cobalt permanent magnets, ferrite permanent magnets and rare earth permanent magnets (including samarium cobalt permanent magnets and neodymium iron boron permanent magnets). The magnetization direction is divided into parallel magnetization and radial magnetization.

-

Wind Power Generation Magnets

Wind energy has become one of the most feasible clean energy sources on earth. For many years, most of our electricity came from coal, oil and other fossil fuels. However, creating energy from these resources causes serious damages to our environment and pollute the air, land and water. This recognition has made many people to turn to green energy as a solution.

-

Neodymium (Rare Earth) Magnets for Efficient Motors

A neodymium magnet with a low degree of coercivity may begin to lose strength if heated to more than 80°C. High coercivity neodymium magnets have been developed to operate at temperatures up to 220°C, with little irreversible loss. The need for a low temperature coefficient in neodymium magnet applications has led to the development of several grades to meet specific operational requirements.

-

Neodymium Magnets for Household Appliances

Magnets are widely used for speakers in TV sets, magnetic suction strips on refrigerator doors, high-end variable frequency compressor motors, air conditioning compressor motors, fan motors, computer hard disk drives, audio speakers, headphone speakers, range hood motors, washing machine motors, etc.