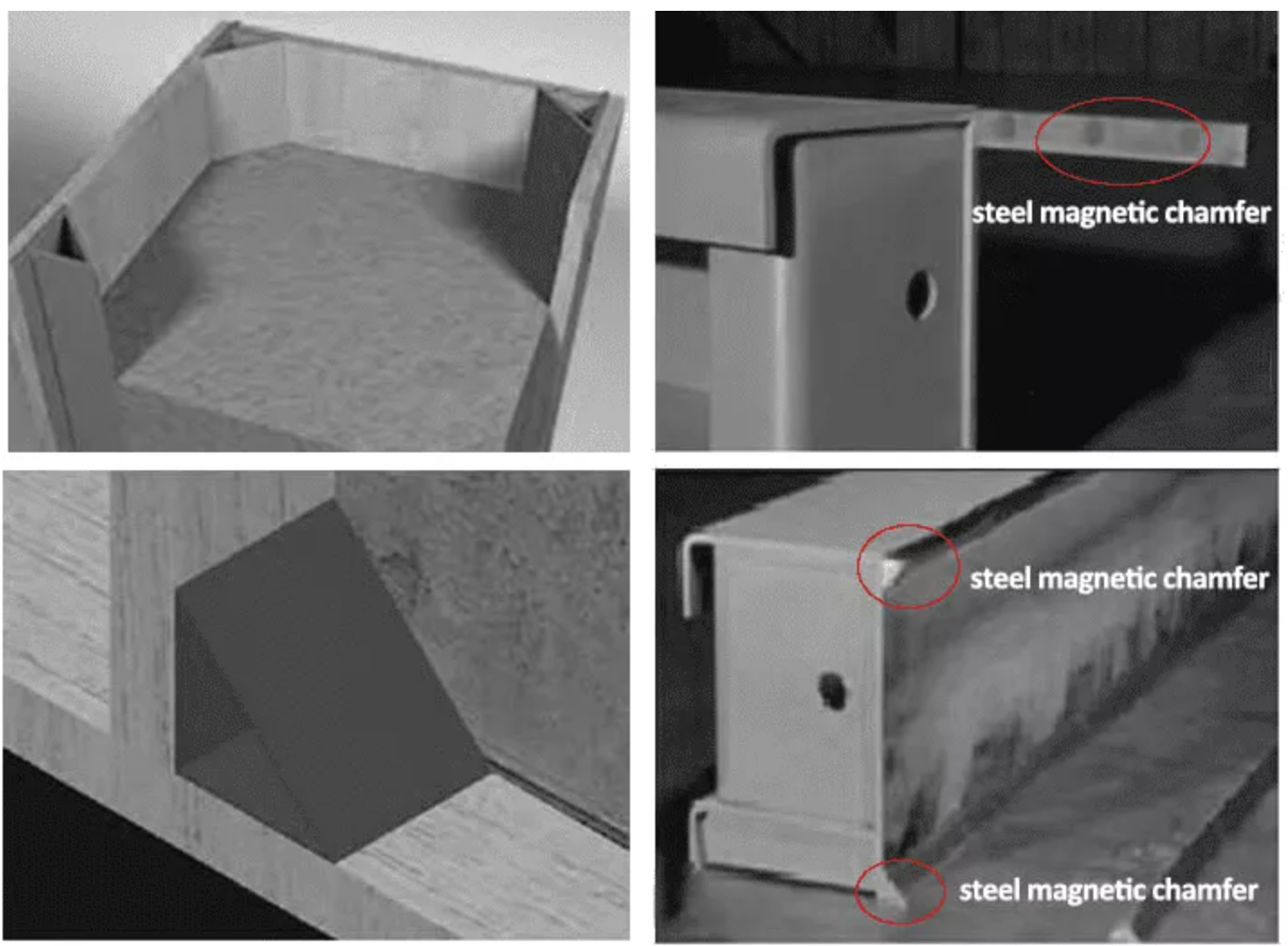

The use of magnetic steel chamfer strips has been widely used in the precast concrete industry for decades. This highly durable material is engineered to withstand extreme working conditions and is often used to securely hold steel surfaces. Its main purpose is to create beveled edges at the corners of concrete siding, and certain formwork applications.

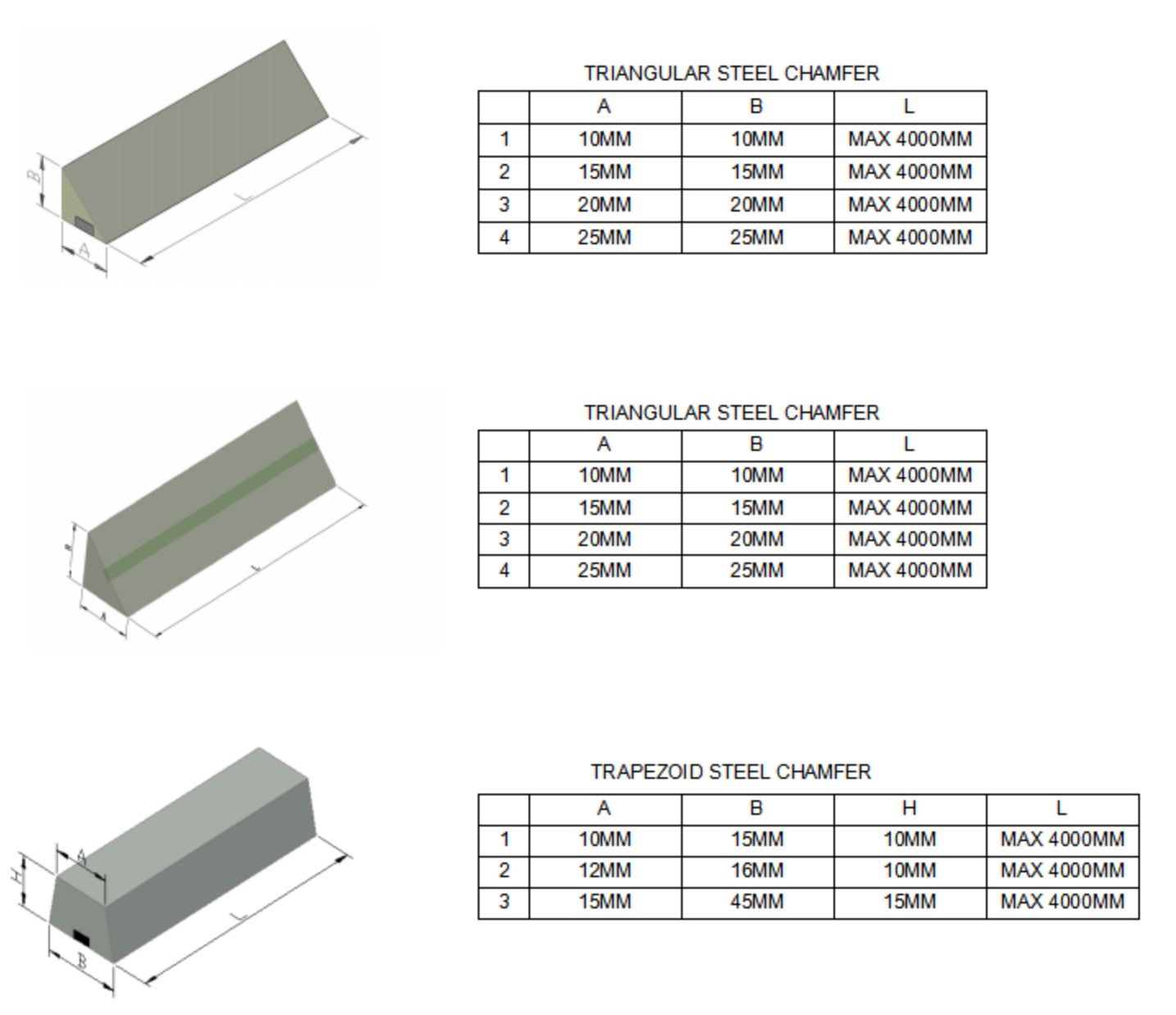

The two most common shapes for these magnetic strips are triangles and trapezoids. Magnetic strips have become one of the most versatile accessories in the precast concrete industry. Manufacturers can choose from a variety of sizes and have the option to fully customize the strips to meet their specific requirements. The versatility of these strips extends to their compatibility with various concrete structures, ensuring a wide range of applications. In addition to its function, magnetic steel chamfering strips also have various advantages.

First, they provide strong adhesion due to their magnetic properties, resulting in a strong connection between concrete surfaces and steel. Second, these strips provide cost and time efficiencies. Their simple installation and removal process saves valuable time during construction, thereby reducing labor costs.

Additionally, their reusable nature eliminates the need for periodic replacement, saving long-term costs. Another notable aspect of these magnetic strips is their compatibility with different architectural designs. They blend seamlessly into various precast concrete structures, enhancing the aesthetics of the final product.

These strips ensure precise and accurate chamfered edges for a polished and professional finish. Magnetic steel chamfer strips play a vital role in ensuring the structural integrity of precast concrete elements. By creating beveled edges, they reduce the risk of chipping and provide greater impact resistance. This increases the durability and longevity of the precast concrete structure, ensuring its stability and functionality for years to come.

Magnetic steel chamfering strip has become an indispensable accessory in the precast concrete industry. Their ability to withstand extreme conditions, their versatility in size and customization, and their numerous advantages make them an essential part of creating high-quality precast concrete structures. With their strong adhesion, cost and time efficiency, compatibility with building designs, and contribution to structural integrity, these magnetic strips continue to play a vital role in the construction industry.

Choose single-sided chamfers when you join steel surfaces one at a time, such as steel tables or panels. When working with two adjacent steel sections, choose double-sided chamfering to ensure secure placement of both surfaces.

Material: Rubber, Q215, Q235 Iron Parts, Neodymium Magnets

Surface Treatment: Magnet Zn or NiCuNi Coating

Max Working Temperature: 80℃

Reusability and long-lasting durability;

Magnetic material encased in steel provides extremely high adhesion;

Improves yield and quality of precast concrete walls Easy handling without magnet pulls during routine use;

Eliminates trenches requiring concrete fill;

Quick and easy positioning, removal and cleaning Precise positioning on the formwork without screws, bolts or welding, avoiding any damage to the formwork table;

Designed to fit seamlessly with steel beds, steel panels and all types of precast rail frames;

Compared with traditional chamfering poles, powerful suction ensures that chamfering poles will not move during watering;

Easy expansion, standardization and mass production.

- While the suction of chamfer strips is not as strong as that of template magnets, it still has a decent amount of suction. Misuse may result in personal injury, damage to the magnet, or damage to the work environment. While our magnetic steel chamfers are user-friendly, taking a few extra precautions will not only protect you but the chamfer itself. Below, we outline safety recommendations before, during, and after use.

- Avoid placing the chamfer vertically as the force of the impact may break the magnet. Instead, position the chamfer rod on one side first, then gently set it into place.

- Although the magnets and steel are treated to prevent rust, chronic lack of cleaning can cause the cement to stick to the chamfer strips, making them difficult to remove. To prolong the life of your chamfer, clean it after each use and apply anti-rust oil to keep it in top working condition.

- Make sure the maximum operating or storage temperature remains below 80°C. Elevated temperatures may cause the chamfer strips to weaken or completely lose their magnetism.

- Keep it away from electronic devices (such as cell phones, laptops, tablets, and computers) and unnecessary ferromagnetic metals.

- Use extreme caution when using chamfers near people with pacemakers. The triangular steel chamfer creates an extremely strong magnetic field that may interfere with the electronic components inside the pacemaker.

- If any concrete or debris is stuck to the chamfer, remove it immediately. For stubborn concrete deposits, gently scrape or polish them.

- Always keep the mold table surface smooth. If there is a hard object between the magnet and the mold table, the strong suction may cause the magnet to deform.

- Always handle triangle chamfers with care. When you're done, stack lightly to prevent tripping or accidentally pinching your hands and fingers.

- We recommend storing chamfers on a plastic or rubber stand to ensure easy access.

- Avoid prolonged exposure to sunlight as high temperatures may cause weakening of magnetism or complete degaussing of magnet chamfers.

- Keep surfaces clean. Although both the magnet and the steel are treated to prevent rust, failing to clean the magnet adequately can cause the cement to stick to the chamfer strip, making it difficult to remove. Therefore, users are strongly advised to clean and grease after each use. Despite the rust-resistant coating on steel surfaces, concrete is alkaline and corrosive, which can cause corrosion on steel surfaces over time.

Established over ten years ago, Honsen Magnetics is a well-known name in the field of permanent magnets and magnetic components manufacturing and sales. Our experienced team oversees the entire production cycle, including machining, assembly, welding, and injection molding. Our products are favored overseas especially in Europe and America for their competitive prices, excellent quality, and our unswerving commitment to customer-centric service.

- More than 10 years experience in permanent magnetic products industry

- Over 5000m2 factory is equipped with 200 advanced Machines

- Have a complete production line from machining, assembling, welding, injection molding

- Have a strong R&D team can provide perfect OEM&ODM service

- Skilled workers & continuous improvement

- Fast shipping & worldwide delivery

- Serve ONE-STOP-SOLUTION ensure efficient & cost-effective purchasing

- Work with big customers & small ones without MOQ

We are committed to providing forward-looking assistance and creative, competitive products, and our goal is to strengthen our market position. Driven by significant advances in permanent magnets and components, we are focused on growth through technological breakthroughs and entering new markets. Led by a Chief Engineer, our skilled R&D department leverages in-house capabilities, cultivates customer relationships, and anticipates market trends with the foresight. Independent groups vigilantly manage international projects and maintain a steady stream of research work.

Quality management is at the heart of our business philosophy. We regard quality as the vitality and guiding principle of the company. Going beyond mere documentation, we seamlessly integrate our quality management system into our processes. This ensures that our products consistently meet and exceed our customers' needs, demonstrating our commitment to a standard of excellence.

At Honsen Magnetics, our core principles are two-fold: ensuring an exceptional customer experience and maintaining an unwavering safety benchmark. These principles apply to our team members and support personal development. The growth of every employee promotes the continuous progress of our enterprise.