Magnetic Assemblies

The magnetic assemblies at Honsen Magnetics are the result of extensive research and development by our team of highly skilled engineers. With unwavering dedication, we have engineered a range of components that not only meet but exceed industry standards. These components are made of carefully selected high-quality magnetic materials to ensure longevity and strength. One of the key features of our magnetic assemblies is their versatility. They come in a variety of sizes, shapes and magnetic strengths and can be used in a variety of applications such as Neodymium Pot Magnet, Halbach Array Magnet, Neodymium Motor Magnet, Precast Concrete Magnet, Magnetic Couplings, Magnetic Bar, Magnetic Tools etc. Whether you need a simple magnetic catch or complex magnetic motor parts, our components can be customized to meet your specific requirements. At Honsen Magnetics, we prioritize quality and adhere to strict quality control measures throughout the manufacturing process. Our magnetic components undergo rigorous testing to ensure they meet the highest standards of performance and durability. This commitment to quality has earned us a reputation for providing superior magnetic solutions to our valued customers. If you are looking for magnetic components combining efficiency, precision and reliability, look no further than Honsen Magnetics. Our magnetic assemblies are designed to meet the diverse needs of various industries and withstand the harshest conditions. With a commitment to excellence, our goal is to provide you with the best magnetic solutions that meet and exceed your expectations. Partner with us today and experience the transformative power of our magnetic assemblies.-

Neodymium Pot Magnets with Countersunk & Thread

Pot Magnets are also known as Round Base Magnets or Round Cup Magnets, RB Magnets, cup magnets, are magnetic cup assemblies comprised of neodymium or ferrite ring magnets encased in a steel cup with a countersunk or counterbored mounting hole. With this type of design, the magnetic holding force of these magnetic assemblies is multiplied many times and is significantly stronger than individual magnets.

Pot magnets are special magnets, which especially the bigger ones, are used in the industry as industrial magnets. The magnetic core of pot magnets is made of neodymium and is sunk in a steel pot in order to intensify the adhesive force of the magnet. That is why they are called “pot” magnets.

-

Strong Rare Earth Disc Countersunk Hole Round Base Pot Magnets D16x5.2mm (0.625×0.196 in)

Pot magnet with countersunk borehole

ø = 16mm, height 5.2 mm ((0.625×0.196 in))

Borehole 3.5/6.5 mm

Angle 90°

Magnet made of neodymium

Steel cup made of Q235

Strength approx. 6 kgs

Low MOQ, customized spec also welcomed according to your requirements

-

Neodymium Pot Magnet Cup Magnet with Countersunk D25mm(0.977 in)

Pot magnet with countersunk borehole

ø = 25mm (0.977 in), height 6.8 mm/ 8mm

Borehole 5.5/10.6 mm

Angle 90°

Magnet made of neodymium

Steel cup made of Q235

Strength approx. 18 kgs~22kgs

Low MOQ, customized is welcomed according to your requirements.

Magnets are available in a variety of shapes. Some are square, while others are rectangular. Round magnets, such as cup magnets, are also available. Cup magnets still generate a magnetic field, but their round shape and small size make them ideal for certain applications. What exactly are cup magnets, and how do they work?

-

Magnetic Name Badge Automatic Production

Product Name:Magnetic Name Badge

Material: Neodymium Magnet+Steel Plate+Plastic

Dimension: Standard or customized

Color: Standard or customized

Shape: Rectangular, Round or customized

The Magnetic Name Badge belongs to a new type of badge. The Magnetic Name Badge uses magnetic principle to avoid damaging clothes and stimulating skin when wearing ordinary badge products. It is fixed on both sides of clothes by the principle of opposite attraction or magnetic blocks, which is firm and safe. Through the rapid replacement of labels, the service life of products is greatly extended.

-

Neodymium Channel Magnet Assemblies

Product Name: Channel Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Rectangular, Round base or customized

Application: Sign and Banner Holders – License Plate Mounts – Door Latches - Cable Supports -

Rubber Coated Magnets with Countersunk & Thread

Rubber coated magnet is to wrap a layer of rubber on the outer surface of the magnet, which is usually wrapped with sintered NdFeB magnets inside, magnetic conducting iron sheet and rubber shell outside. The durable rubber shell can ensure the hard, brittle and corrosive magnets to avoid damage and corrosion. It is suitable for indoor and outdoor magnetic fixation applications, such as for vehicle surfaces.

-

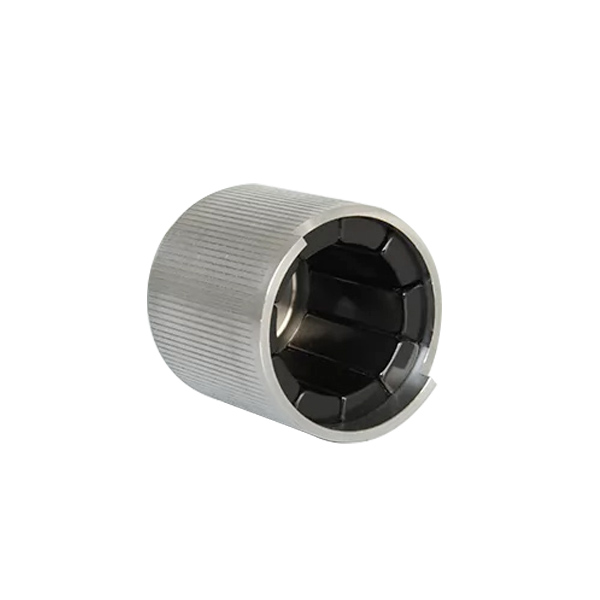

Magnetic Rotor Assemblies for High-Speed Electric Motors

Magnetic rotor, or permanent magnet rotor is the non stationary part of a motor. The rotor is the moving part in an electric motor, generator and more. Magnetic rotors are designed with multiple poles. Each pole alternates in polarity (north & south). Opposite poles rotate about a central point or axis (basically, a shaft is located in the middle). This is the principal design for rotors. Rare-earth permanent magnetic motor has a series of advantages, such as small size, light weight, high efficiency and good characteristics. Its applications are very extensive and extend all over fields of aviation, space, defense, equipment manufacturing, industrial and agricultural production and daily life.

-

Permanent Magnetic Couplings for Drive Pump & magnetic mixers

Magnetic couplings are non-contact couplings that use a magnetic field to transfer torque, force or movement from one rotating member to another. The transfer takes place through a non-magnetic containment barrier without any physical connection. The couplings are opposing pairs of discs or rotors embedded with magnets.

-

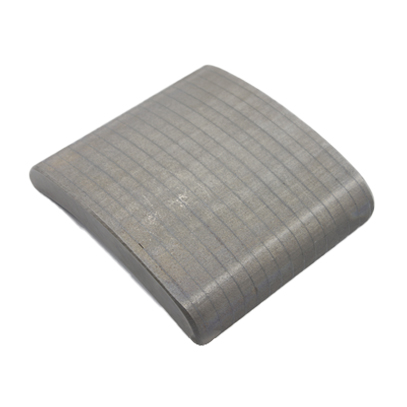

Laminated Permanent Magnets to reduce Eddy Current Loss

The purpose to cut a whole magnet into several pieces and apply the together is to reduce eddy loss. We call this kind magnets “Lamination”. Generally, the more pieces, the better the effect of eddy loss reduction. The lamination will not deteriorate the overall magnet performance, only the flux will slightly affected. Normally we control the glue gaps within a certain thickness using special method to control each gap has the same thickness.

-

N38H Neodymium Magnets for Linear Motors

Product Name: Linear Motor Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Neodymium block magnet or customized -

Halbach Array Magnetic System

Halbach array is a magnet structure, which is an approximate ideal structure in engineering. The goal is to generate the strongest magnetic field with the smallest number of magnets. In 1979, when Klaus Halbach, an American scholar, conducted electron acceleration experiments, he found this special permanent magnet structure, gradually improved this structure, and finally formed the so-called “Halbach” magnet.

-

Magnetic Motor Assemblies with Permanent Magnets

Permanent magnet motor generally can be classified into permanent magnet alternating current (PMAC) motor and permanent magnet direct current (PMDC) motor according to current form. PMDC motor and PMAC motor can be further divided to brush/brushless motor and asynchronous/synchronous motor, respectively. Permanent magnet excitation can significantly decrease power consumption and strengthen the running performance of the motor.