What is Magnetic Assemblies?

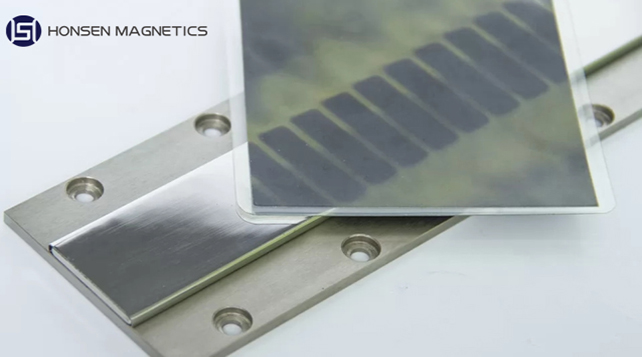

Magnetic Assemblies are permanent magnets like Sintered Neodymium Iron Boron Magnets, Ferrite Magnets, or Samarium Cobalt Magnets, and AlNiCo Magnets that are assembled into non-magnetic materials like Carbon Steel, Stainless Steel, Copper, Aluminum, Nylon, Teflon, and so on. By combining different magnetic elements, such as magnets, metal components, and non-magnetic materials, Magnetic Assemblies can provide unique functions and enhance the overall performance of magnetic systems.

Magnetic Assemblies, such as mounting pot magnets, are designed to enhance the magnetic circuit and increase the pulling force strength, they have the potential to be more than 30 times stronger compared to the magnet itself alone.

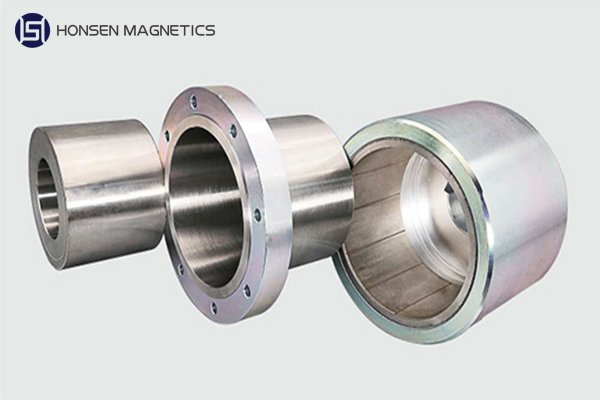

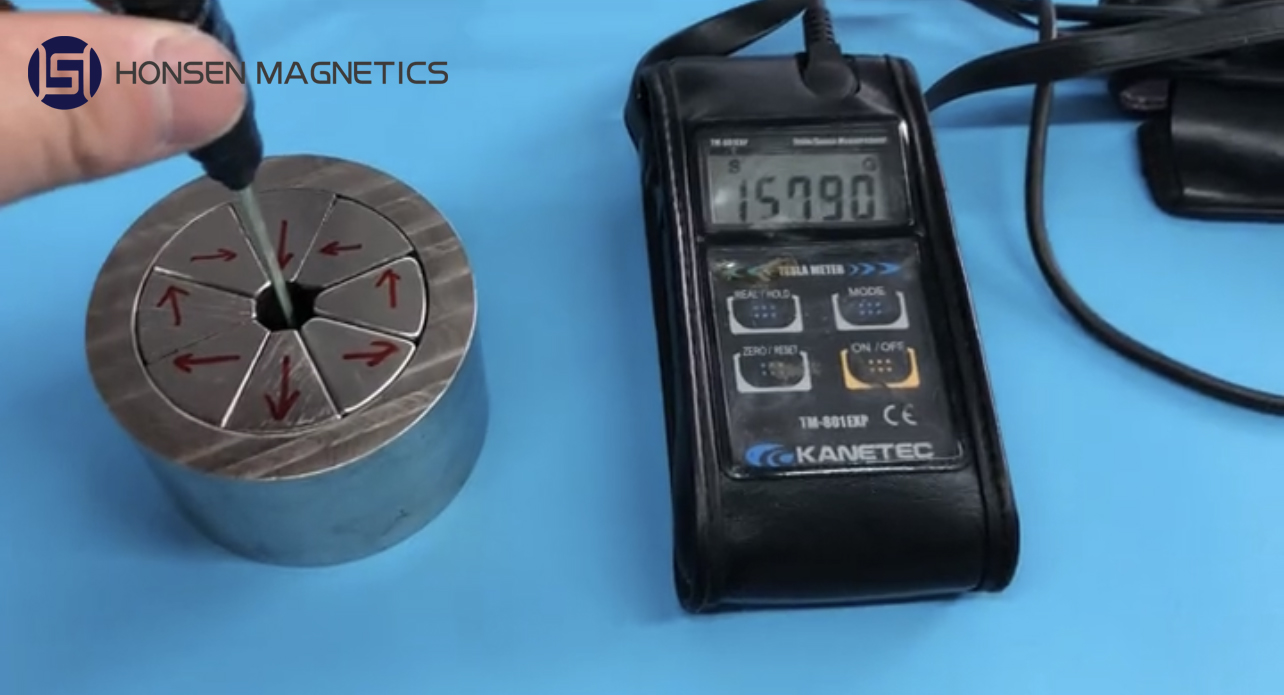

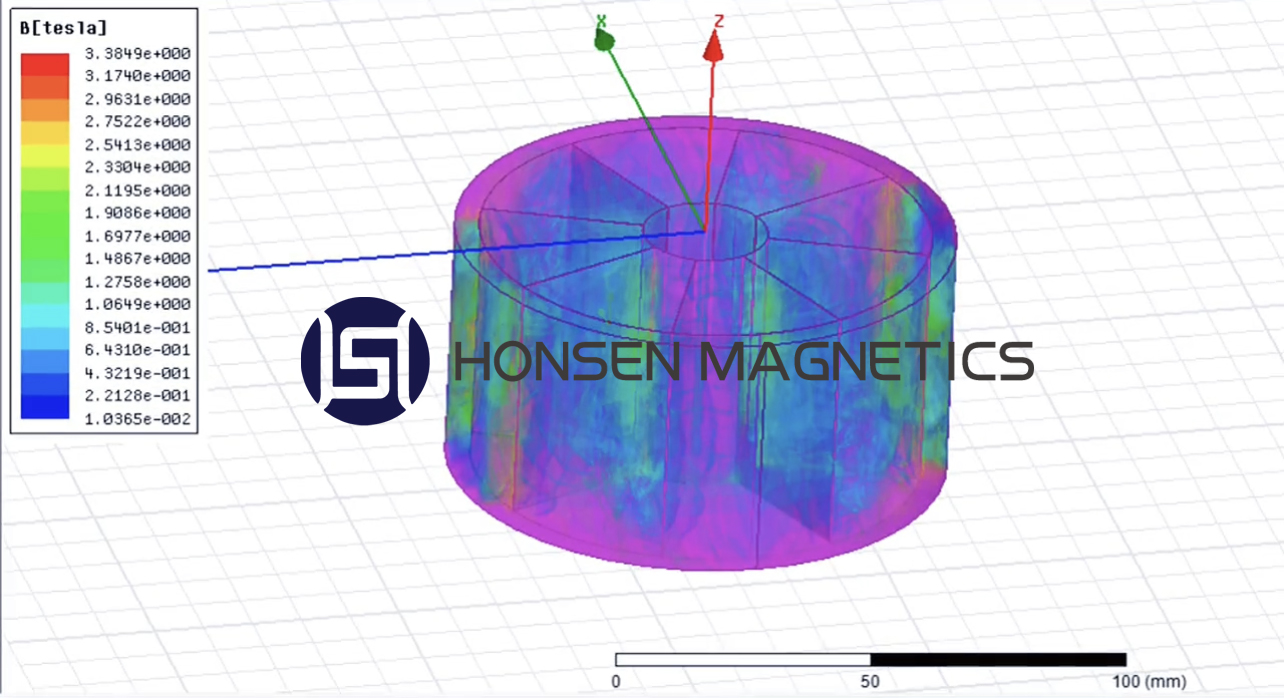

Magnetic Rotors are frequently utilized in electric motors and generators. It consists of a central core made of magnetic material with multiple magnets arranged around its circumference. When an electric current passes through the coils surrounding the rotor, it generates a magnetic field that interacts with the magnets on the rotor.

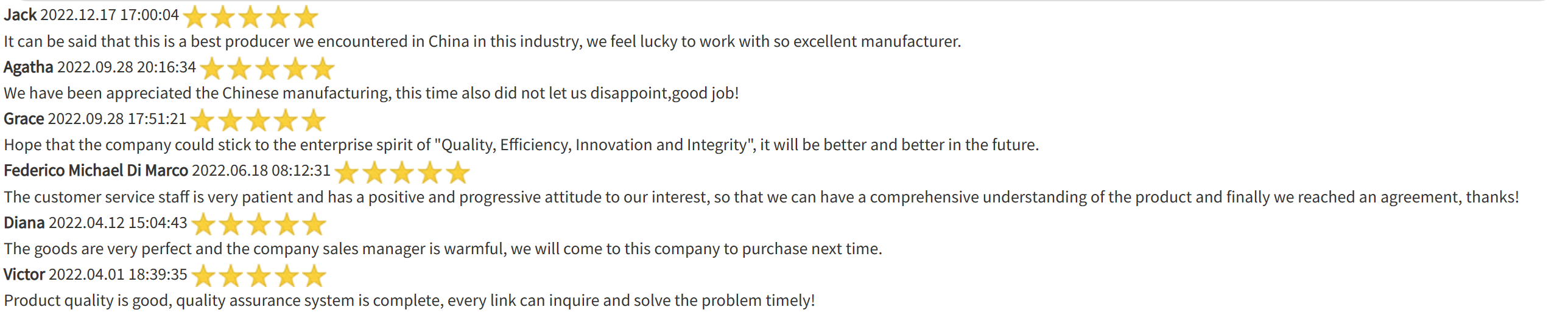

Magnetic Coupling is a new type of coupling that connects the prime mover and the working machine through the magnetic force of the permanent magnet. Magnetic Coupling does not require direct mechanical connection, but utilizes the interaction between rare earth permanent magnets, utilizing the magnetic field to penetrate a certain spatial distance and the characteristics of material materials to transmit mechanical energy.

Magnetic Separators are used to separate magnetic materials from non-magnetic materials in industries such as mining, recycling, and food processing. By arranging magnets in a specific way, magnetic separators can attract and remove unwanted magnetic particles from materials, ensuring product purity and improving efficiency.

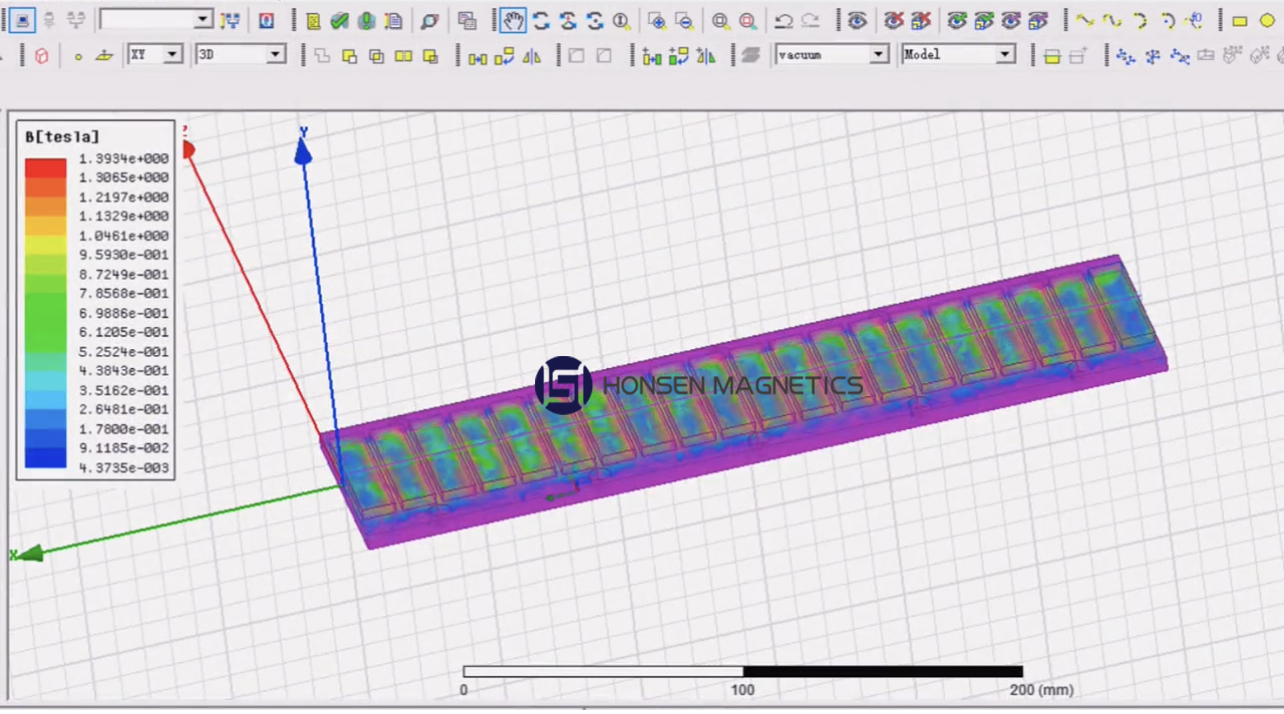

Linear Motor Magnets are the essential components used in linear motors. Linear motors are a type of electromagnetic device that converts electrical energy into linear motion. Linear motor magnets are typically made from rare earth materials, such as neodymium magnets, which offer high magnetic strength and stability. These magnets are designed to produce a strong magnetic field that interacts with the motor's coils, producing the desired linear motion.

Halbach Array Magnets are a special type of magnet configuration that creates a strong and focused magnetic field on one side while canceling it out on the other. This arrangement is achieved by arranging a series of magnets in a specific pattern. Halbach array magnets have various applications, including in electric motors, magnetic resonators, and magnetic levitation systems.

Magnetic Assemblies are widely used in industries and daily life, such as in robotics, defense, appliances, transportation, motors & braking systems, security & anti-theft devices, medical devices, agricultural equipment, navigational equipment, fixtures, displays, signs, latches, tools and more.

Customized Magnetic Assemblies

Honsen Magnetics provides our customers with all kinds of magnetic solutions of Magnetic Assembies. We can also design to produce complete Magnetic Assemblies and components with incorporate the magnets with a non-magnetic application or housing. From simple ones to complex motors and rotor magnets, magnetic couplings, or audio equipment sub-assemblies, we can handle any industrial or commercial magnet projects. Our experienced team of engineers and skilled workers offers you a wide range of magnetic demands.

Typical Applications of Magnetic Assemblies

-Rotors for high end sport cars

-Rotors for aviation applications

-Scientific applications (wigglers, beam guiding systems and undulators)

-Aircraft and space applications

-High rpm rotors for motors or generators

-Large, very small, and tricky assemblies

-Extremely precise assemblies

WHY HONSEN MAGNETICS

With more than ten years of experience, Honsen Magnetics has consistently excelled in the manufacturing and trading of Permanent Magnets and Magnetic Assemblies. Our diverse production lines encompass crucial processes such as machining, assembly, welding, and injection molding, enabling us to provide customers with a comprehensive solution. These capabilities ensure that we produce high-quality products that meet the most stringent standards.

At Honsen Magnetics, our customer-centric approach is the cornerstone of our operations. We prioritize the needs and satisfaction of our clients above all else, delivering exceptional products and outstanding service throughout the entire customer journey. Our reputation extends beyond borders, as we have gained immense popularity in Europe, America, Southeast Asia, and other countries. By consistently offering reasonable prices and maintaining superior product quality, we have earned the trust and positive feedback of our customers, solidifying our position in the industry.

Honsen Magnetics is a trusted and renowned supplier in the field of Permanent Magnets and Magnetic Assemblies. With our extensive experience, cutting-edge manufacturing processes, skilled workforce, and unwavering commitment to customer satisfaction, we continue to thrive and make a meaningful impact in the global market.

OUR ADVANTAGES

- More than 10 years experience in permanent magnetic products industry

- Over 5000m2 factory is equipped with 200 advanced Machines

- Have a complete production line from machining, assembling, welding, injection molding

- With 2 production plants, 3000 tons/year for magnets and 4m units/month for magnetic products

- Having strong R&D team can provide perfect OEM&ODM service

- Have the certificate of ISO 9001, IATF 16949, ISO14001, ISO45001, REACH, and RoHs

- Strategic cooperation with the top 3 rare blank factories for raw materials

- High rate of automation in Production & Inspection

- 0 PPM for Magnets & Magnetic Assemblies

- FEA simulation to calculate and optimize magnetic circuits

- Skilled workers & continuous improvement

- We only export qualified products to customers

- We enjoy a hot market in most parts of Europe, America, Asia & others

- Fast shipping & worldwide delivery

- Offer free magnetic solutions

- Bulk discounts for larger orders

- Serve ONE-STOP-SOLUTION ensure efficient & cost-effective purchasing

- 24-hour online service with first-time response

- Work with big customers & small ones without MOQ

- Offer all kinds of payment methods

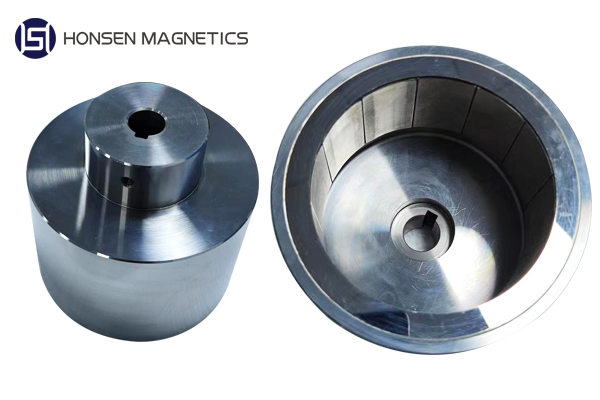

PRODUCTION FACILITIES

Since our establishment, our primary focus has always been on ensuring the highest quality of our products. We continuously strive to improve both our products and production processes, guaranteeing that you will receive only the best-quality items. Our team consists of experienced professionals who excel at every stage of production.

To ensure unparalleled product and process quality, we employ Advanced Product Quality Planning (APQP) and Statistical Process Control (SPC) systems. These systems carefully monitor and manage conditions during crucial manufacturing stages. We want to reassure you that our commitment to delivering exceptional products remains resolute. Through our dedication to constant improvement and the implementation of rigorous quality control measures, we are committed to our promise of providing you with the finest products.

With our competent workforce and robust quality management systems, we have great confidence in our ability to consistently meet and surpass your expectations. Your satisfaction with our high-quality offerings is our ultimate objective.

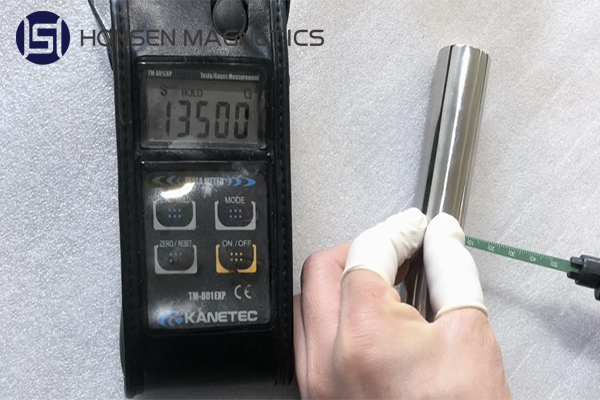

QUALITY & SAFETY

Quality management is the fundamental principle that drives our organization, serving as the foundation of our success. At Honsen Magnetics, we firmly believe that quality is not just an abstract concept; it guides and influences every decision and action we take.

Our steadfast commitment to excellence is evident in all aspects of our operations. We have embraced a comprehensive approach to quality management, seamlessly integrating it into every facet of our organization. This all-encompassing integration ensures that quality is not an afterthought but a fundamental aspect of our processes and products. From sourcing raw materials to production and customer service, our quality management system permeates every stage. We are dedicated to consistently exceeding our customers' expectations.

By adhering to strict quality control measures and harnessing cutting-edge technology, we meticulously craft products of unparalleled excellence. Our dedication to surpassing customer expectations is not mere rhetoric; it is deeply ingrained in our organizational culture.

Our unwavering commitment to quality management is the key to our success. By seamlessly integrating it into our operations, we consistently deliver exceptional products that embody our unwavering commitment to excellence.

PACKING & DELIVERY

TEAM & CUSTOMERS

At Honsen Magnetics, we understand that our ability to meet customer needs and maintain a high level of safety practices is crucial to our success. We also recognize the importance of investing in the personal development of our employees. To nurture a conducive environment, we actively encourage the professional and personal growth of our workforce. We provide numerous opportunities for training, skill enhancement, and career advancement, allowing our employees to reach their full potential. We believe that investing in personal development is essential for long-term success.

By continuously improving their skills and knowledge, our employees become more valuable assets, enhancing the overall strength and competitiveness of our business. Promoting personal development within our workforce not only lays the foundation for our ongoing success but also cultivates a culture of continuous improvement. By prioritizing customer satisfaction and safety while also emphasizing employee growth and development, we create a well-rounded and robust business environment. These principles of satisfying customers, ensuring safety, and fostering employee growth are the fundamental pillars that underpin our business and form the basis for our continued success.

CUSTOMERS' FEEDBACK