Ferrite block magnets are sometimes known as ceramic block magnets, rectangle magnets, or bar magnets. There are many different sizes, diameters, and scales or proportions available for these permanent magnets. Our Ferrite Blocks are a cost-effective alternative for many magnetic applications despite their high quality.

Magnets made of ferrite magnetic material are adaptable and useful for a variety of applications.

Ferrite blocks must be machined using a diamond wheel since they are brittle and hard, ideally before magnetization.

Ceramic Magnetic Blocks are ideal for both commercial and domestic applications. Applications for industrial sweeping and separation frequently use large ceramic block magnets. Taking undesired shrapnel out of dangerous regions, for instance. Smaller Ferrite blocks are frequently employed in sensors, DC motors, and a variety of handicrafts.

Applications of Ferrite Block Magnets

Magnetos utilized in lawnmowers and outboard motors, DC brushless motors, magnetic resonance imaging (MRI), and DC permanent magnet motors (used in cars),

Separators (separate ferrous material from non-ferrous) (separate ferrous material from non-ferrous), are used in magnetic assemblies that are intended to lift, hold, retrieve, and separate objects.

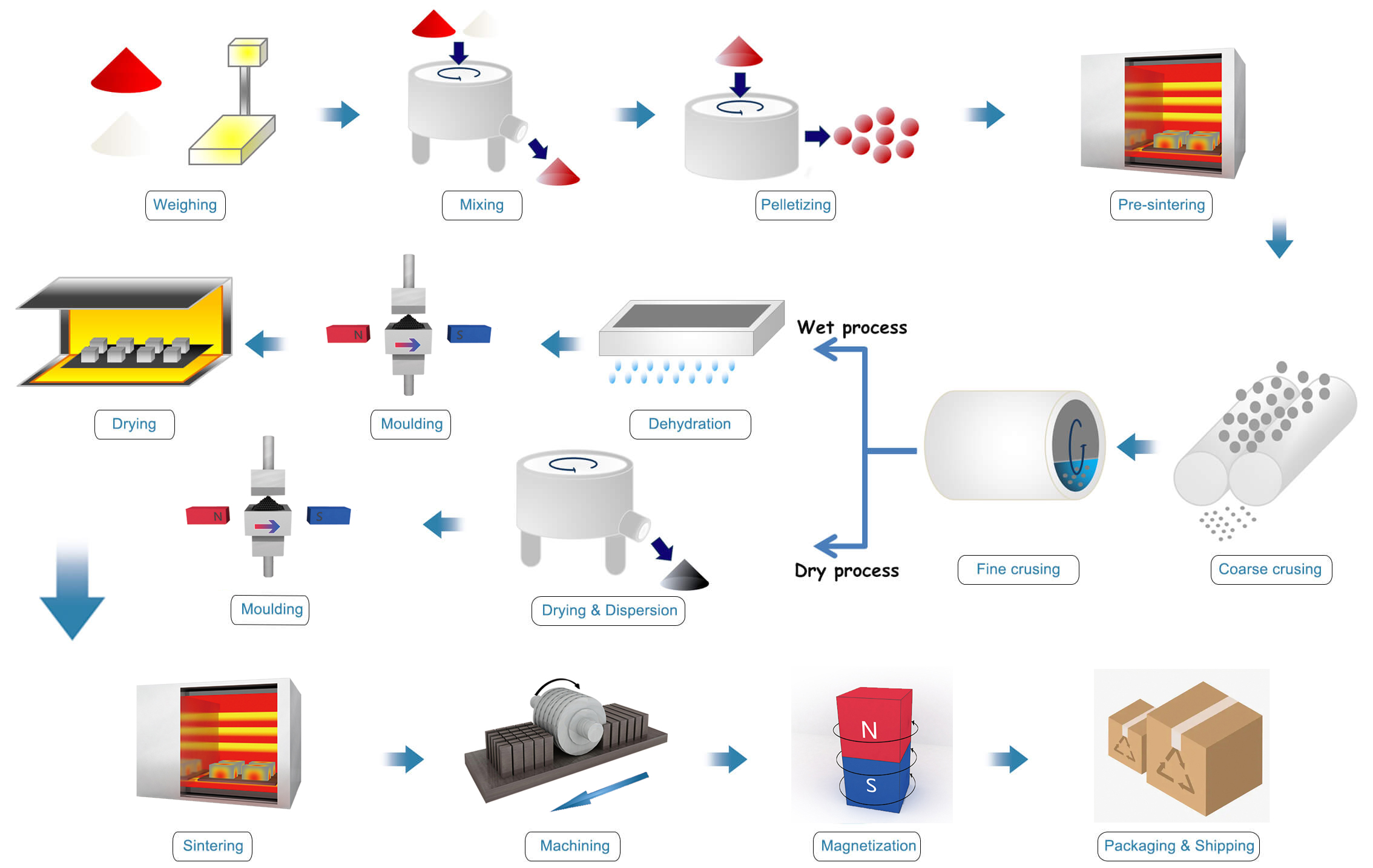

Manufacturing Process of Ferrite Magnets

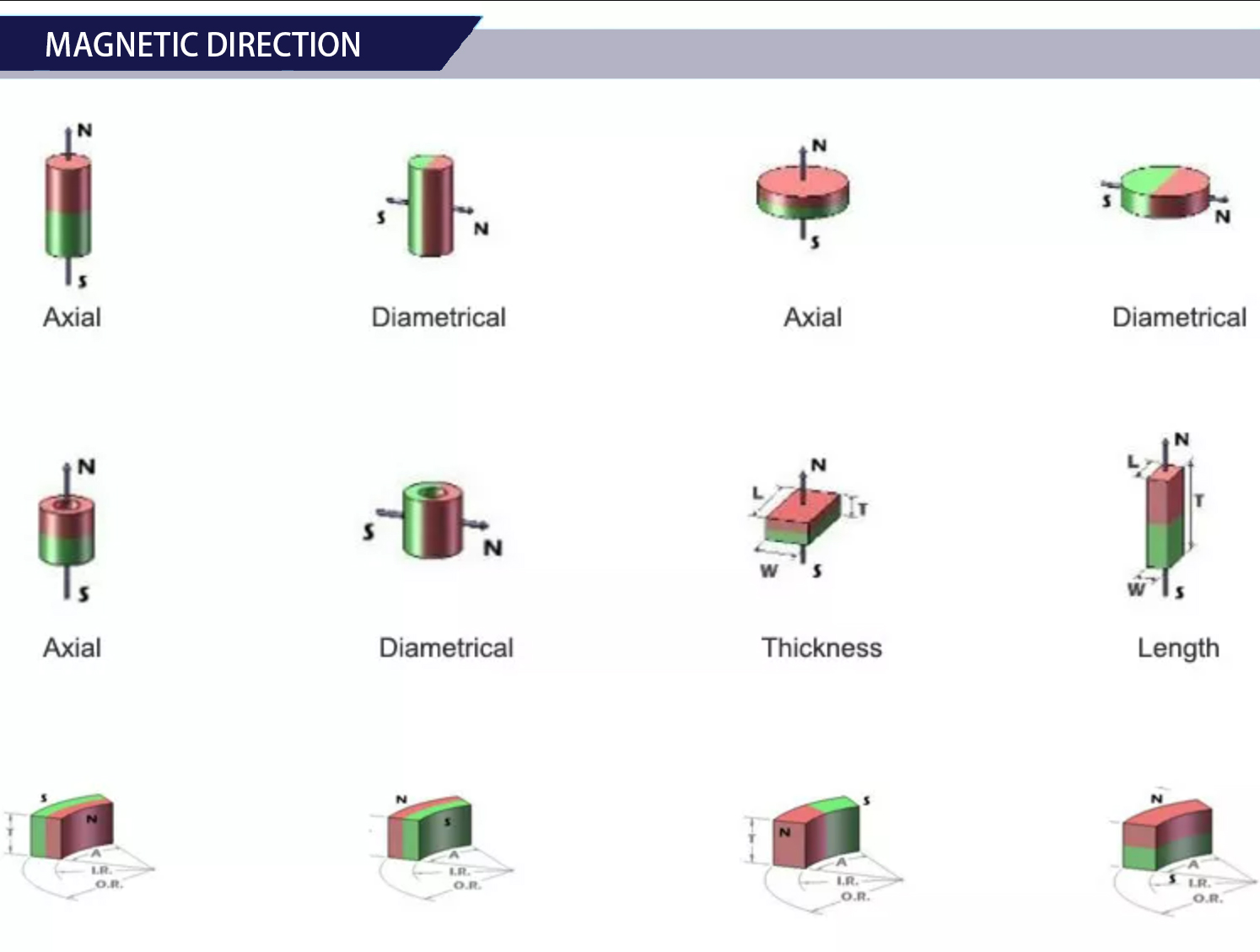

Magnetic Direction

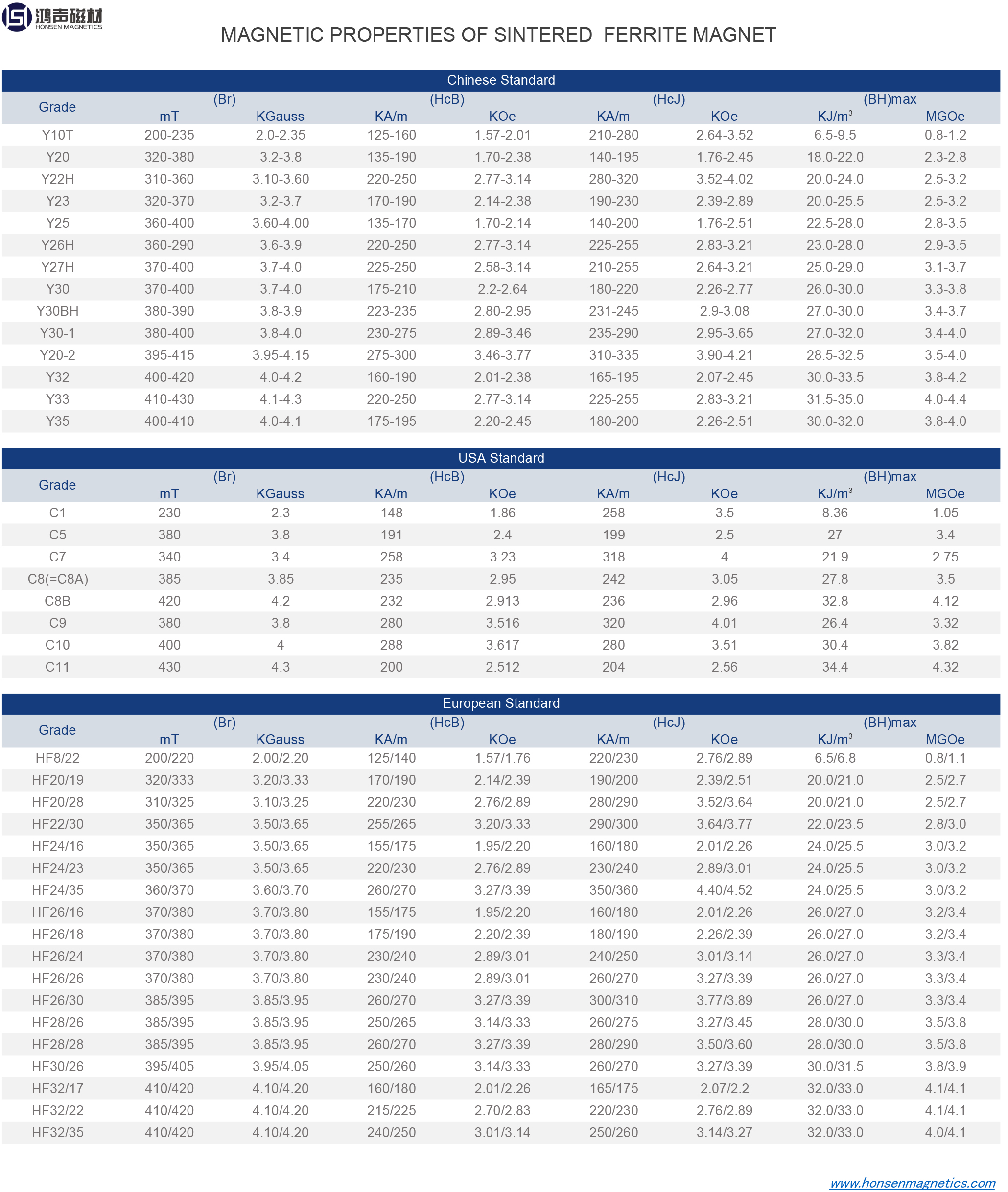

Magnetic Properties

Applications

Why Honsen Magnetics

Our complete production line guarantees production capacity from raw materials to finished products

We serve ONE-STOP-SOLUTION to ensure customers efficient and cost-effective purchasing.

We test each piece of magnets to avoid any quality problem for customers.

We offer different types of packaging for customers to keep products & transportation safe.

We work with big customers as well as small ones without MOQ.

We offer all kinds of payment methods to facilitate customers' purchasing habits.