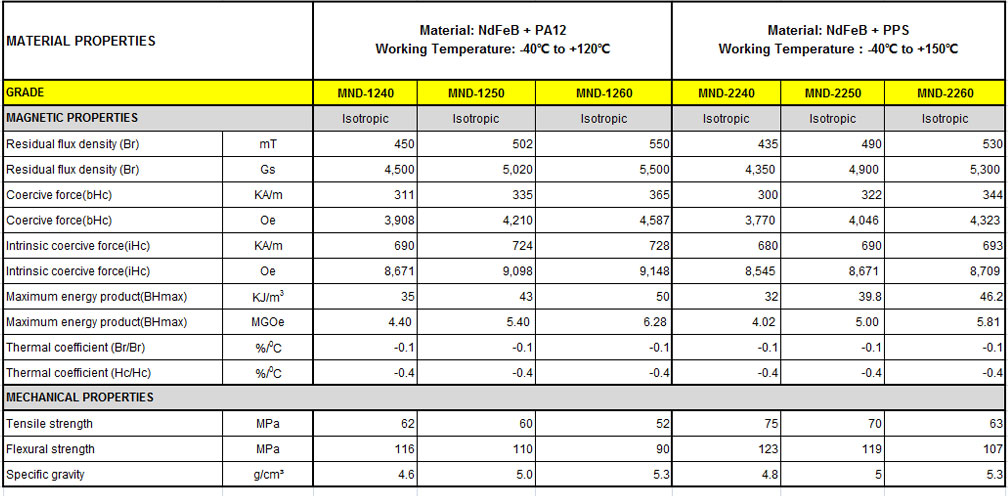

One of the key benefits of injection molded nylon magnets is their excellent magnetic performance, which is comparable to traditional sintered magnets. They also offer exceptional dimensional stability, mechanical strength, and resistance to corrosion and temperature variations, making them ideal for use in harsh environments.

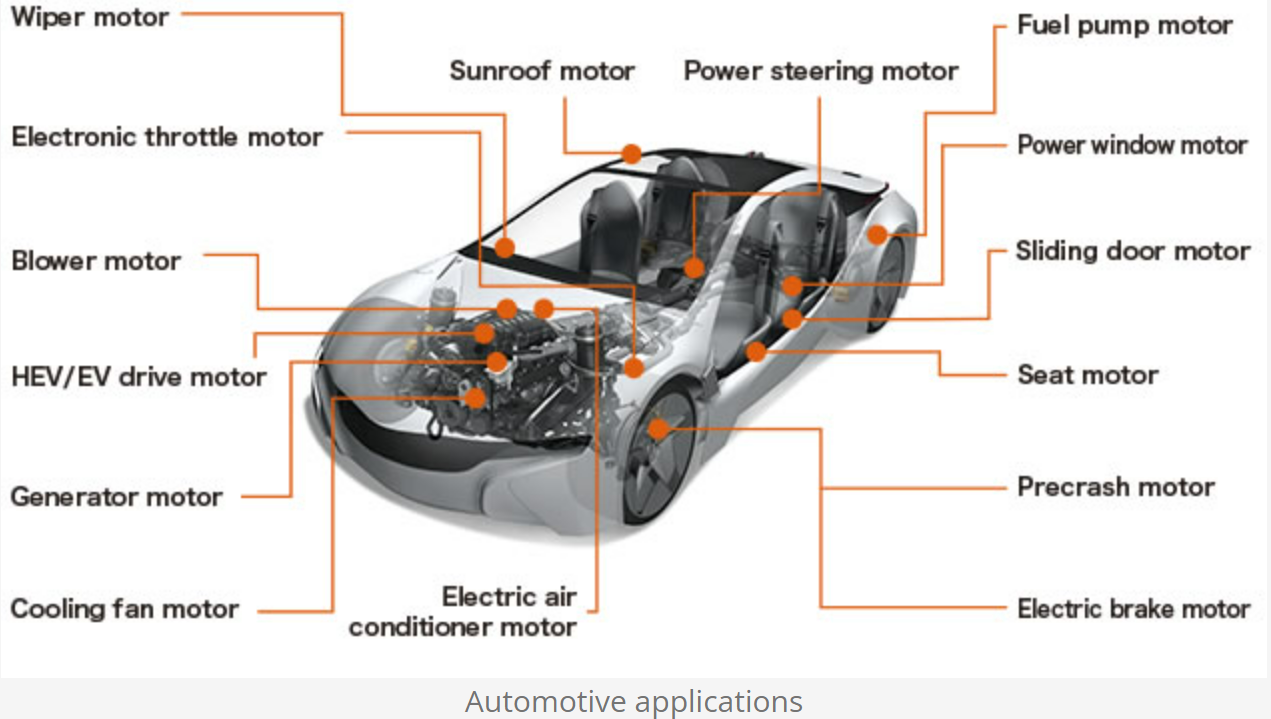

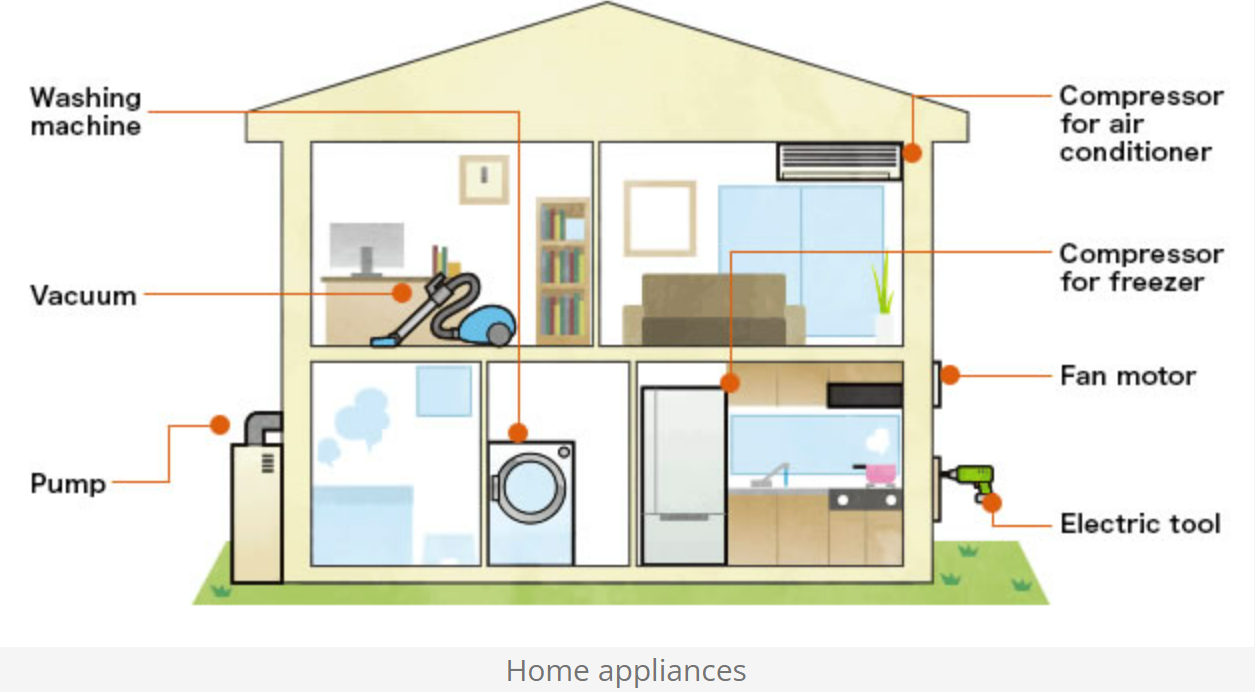

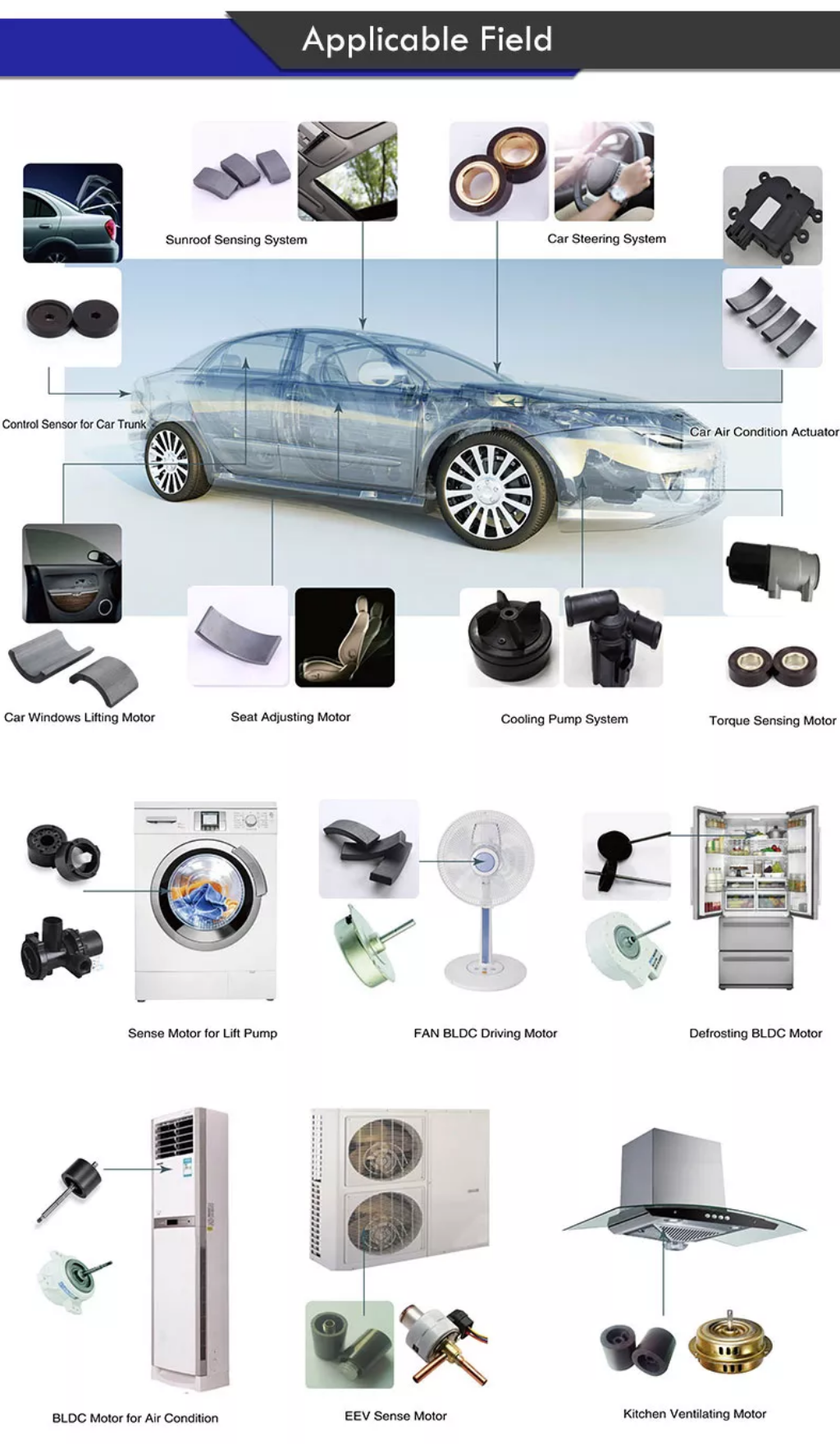

Injection molded nylon magnets can be produced in a variety of shapes and sizes, including complex shapes with multiple poles and customized geometries. This makes them highly versatile and suitable for use in a wide range of applications, such as motors, sensors, actuators, and magnetic couplings.

In addition, injection molded nylon magnets can be customized to meet the specific requirements of different applications, such as magnetic field strength, temperature range, and resistance to demagnetization. This makes them a flexible and cost-effective solution for producing high-performance magnetic components.

Overall, injection molded nylon magnets are a durable, efficient, and cost-effective solution for producing motor and sensor components with superior magnetic performance and dimensional stability. With their ability to withstand harsh environments and be customized to meet specific application requirements, these magnets are an ideal choice for various industries.

Performance Table:

Application: