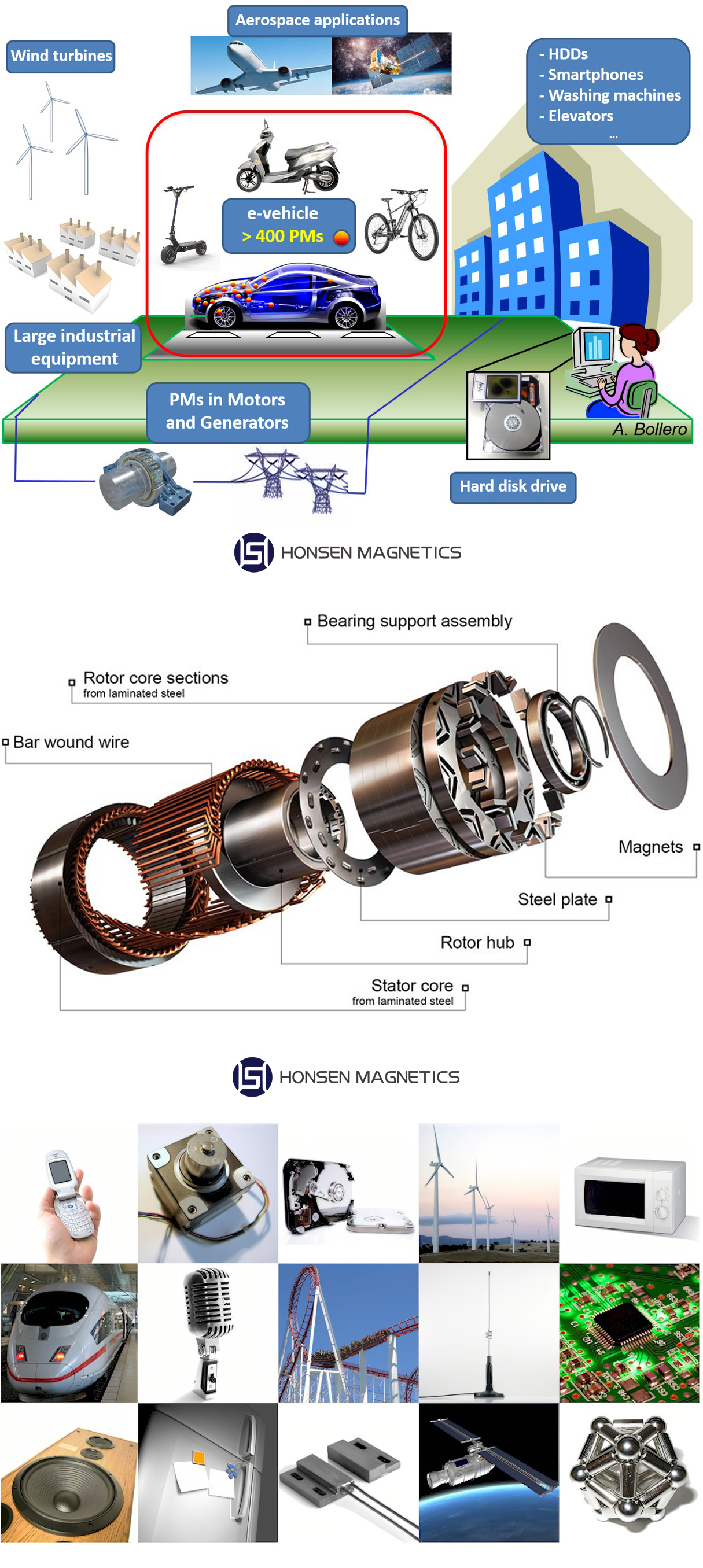

Industrials & Applications of Permanent Magnets

Honsen Magnetics offers a comprehensive range of magnets and magnetic assemblies for various industries. From customized solutions to standard products, our team designs and produces magnets that meet your specific requirements. Whether you need samples or large-scale production, we are here to assist you. Contact us at Honsen Magnetics by a call or email to send us any inquiry, we'll support you to your satisfaction.

Magnetic Separators

Water Conditioning

Computer Disc Drives Speakers

Servo Motors

Acrylic Panels

Binder closure POS Displays

Flow control Systems

Metal Separation

Mining Construction Designing

Printing

Generators

Holding and other

Industrial Purposes.

Magnetic Separators

DC Motors

Magnetos

Door Catches

Water Conditioning

Speakers

Switches

Craft

Games for kids

Science Experiments Therapeutic

Marine Applications

Medical

High-Performance Motors

Accelerometers & Gyroscopes in aircraft, Marine & Spacecraft

Hole Drilling

Guitar Pick-ups

Security Sensors

Coin acceptors

Relays

Controls

Cow magnets

Jigs & fixtures, holding and Gripping applications

Educational facilities

Experimental applications

POS Displays

Fridge Magnets

Custom Extrusions

Promotional Magnets

Invitations Cards

Business Cards

Identifiers

Car Signs

Craft

Arts

General Hobbies

Other Commercial Purposes

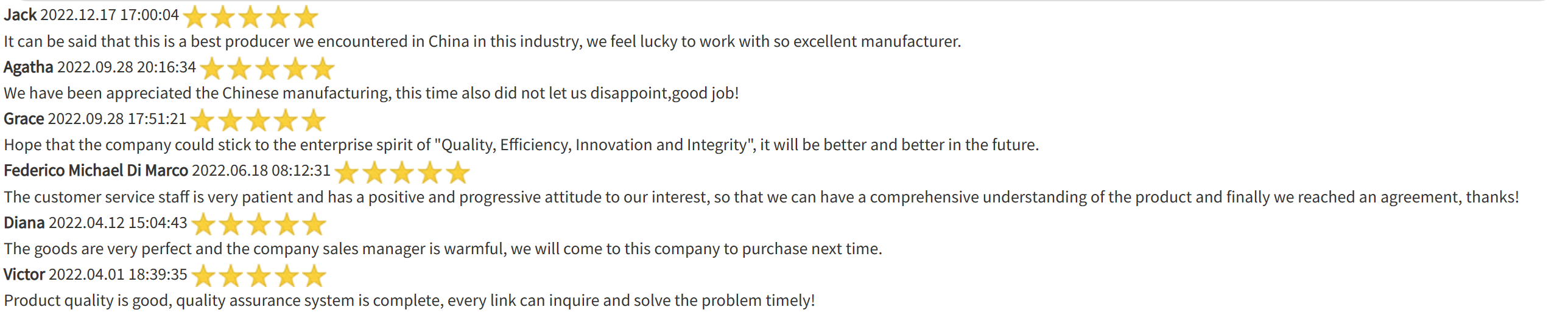

Main Applications

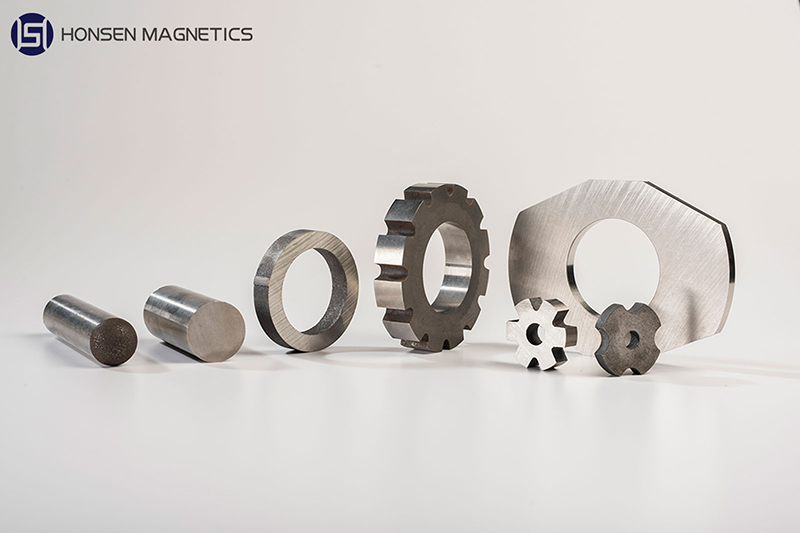

Neodymium magnets, also known as NdFeB magnets, are incredibly powerful and versatile magnets. Due to their superior strength, they are widely used in various applications. One common application of neodymium magnets is in the field of electronics. These magnets are used in speakers, headphones, and microphones to enhance sound quality and improve overall performance. Neodymium magnets are essential in magnetic resonance imaging (MRI) machines, where they generate strong magnetic fields to produce detailed images of the body. With their exceptional magnetism, neodymium magnets continue to revolutionize multiple industries. At present, high-performance NdFeB permanent magnet materials are mainly used in the fields of new energy, energy conservation, and environmental protection. The application industries of NdFeB magnets include wind power generation, new energy vehicles, and auto parts, energy-saving frequency conversion air conditioning, energy-saving elevators, robots, and intelligent manufacturing.

Ferrite magnets, also known as Ceramic magnets, are widely used in various industries due to their affordability and excellent performance at high temperatures. They can be used in loudspeakers, motors, transformers, and magnetic separators. In speakers, ferrite magnets play a vital role in producing sound by interacting with the speaker coil. They are also commonly used in electric motors due to their stability and ability to withstand high temperatures. Transformers rely on ferrite magnets to efficiently transfer energy between circuits. Ferrite magnets are useful in magnetic separators to remove impurities from materials in industries such as mining and recycling. Ferrite magnets are valued for their reliability and cost-effectiveness in a wide range of applications.

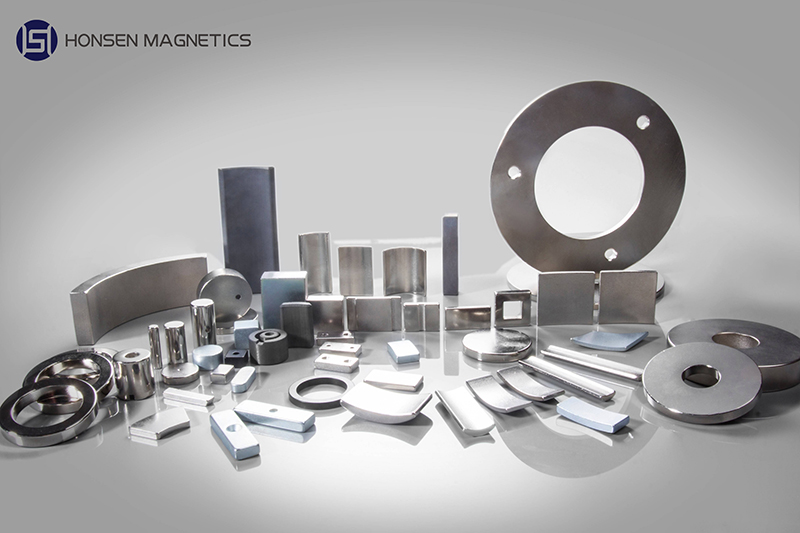

SmCo magnets, short for Samarium Cobalt magnets, are highly recognized for their exceptional magnetic properties. With their strong magnetic field, high coercivity, and resistance to demagnetization, they find numerous applications in various industries. SmCo magnets are widely used in the aerospace industry for applications such as aircraft sensors, actuators, and motors due to their stable performance at high temperatures. They are also extensively utilized in the medical field, particularly in magnetic resonance imaging (MRI) machines and medical devices, where their high magnetic field strength is crucial. Furthermore, SmCo magnets are employed in quality control instruments, precision instruments, and sensors, as well as in the automotive industry for electric power steering systems. Their exceptional performance and durability make SmCo magnets invaluable in applications that require strong and reliable magnetic fields.

AlNiCo magnets, short for Aluminum-Nickel-Cobalt magnets, are widely used in various applications due to their unique magnetic properties. With their excellent temperature stability, high magnetic strength, and corrosion resistance, they find extensive use in industries such as automotive, manufacturing, and electronics. AlNiCo magnets are commonly used in loudspeakers, electric motors, and generators due to their capability to generate strong magnetic fields. Their stability and durability also make them ideal for applications in sensors, relays, and switches. AlNiCo magnets are utilized in holding systems, magnetic chucks, and magnetic separators in metalworking industries. Their versatility and reliability make AlNiCo magnets an essential component in many devices and systems that require strong and consistent magnetic fields.

Flexible magnets, also known as Rubber Magnets, have a wide range of applications due to their flexibility and magnetic properties. They are commonly used in advertising and promotional materials, such as fridge magnets and magnetic business cards. The flexibility of these magnets allows them to be easily cut and shaped into various sizes and designs, making them versatile for creative applications. They are also utilized in the automotive industry for decorative purposes and as a component in car signs and vehicle graphics. Flexible magnets are used in educational settings for interactive learning tools, magnetic boards, and teaching aids. Their ease of use and durability make them suitable for a variety of applications in industries such as crafts, retail, and education.

The Main Magnet Applications:

- Sensor Magnet / Magnet Sensor Triggering

- Magnetic Torque Couplers / Magnetic Linear Couplers

- Magnetic Dipoles

- Voice Coil Motors (VCM)

- Magnetron Magnets & Magnet Packs

Industries Served

- Industrial / Manufacturing

- Aerospace / Defense

- Recycling / Tramp Metal Removal Research

- Medical

- Thin Film Deposition / Sputtering

- Semiconductor

-Computer Hard Drive Magnets

-Microphones

-Headphones

-Dentures

-Loudspeakers

-Magnetic Pump Couplings

-Door Catches

-Magnetic Suspension

-Motors & Pumps (e.g. washing machines, drills, food mixers, vacuum cleaners, hand dryers, medical devices, servo motor, micro motor, vibration motor, VCM, CD DVD-ROM)

-Generators (e.g. Wind turbines, Wave Power, Turbo Generators, etc.)

-Sensors

-Orthopedics

-Halbach Arrays

-Jewelry

-Healthcare

-MRI and NMR applications

-Magnetic Separators

-TWT (Transverse Wave Tube)

-Magnetic Bearings

-Lifting Apparatus

-Limpet Pot Magnets

-Starter motors

-ABS systems

-Fans Eddy Current

-Brakes

-Alternators

-Meters (electric energy meter, water meter)

-Magnetic Clamps

-Magnetic Levitation

-Surgical components and minimally invasive devices

-Endoscopic assemblies

-Hard disk drives

-Electric motors in cordless equipment

-Fasteners

-Receiver

-Stage sound

-Car sound

-Permanent Magnet Mechanism Vacuum Circuit Breaker

-Magnetic Holding Relay

-Reed

-Magnetic crane

-Magnetic machine

-Nuclear Magnetic Resonance Instrument

-Magnetic Resonance Imaging

-Medical Equipment

-Magnetic Therapy Health Care Products

-Magnetization Energy Saver

-Magnetized Wax Corrosion Inhibitor

-Pipeline Descaling Device

-Magnetic Fixture

-Automatic Mahjong Machine

-Magnetic Lock

-Raft Gift Packaging

-Magnotherapy

-Audio Equipment

-Lifting Large Loads

-Business Displays and Signage

-DIY Projects

-Home and Wall Décor

- Electromagnets & Coils

- Aerospace

WHY HONSEN MAGNETICS

With over a decade of experience, Honsen Magnetics has consistently excelled in the manufacturing and trading of Permanent Magnets and Magnetic Assemblies. Our extensive production lines encompass various crucial processes such as machining, assembly, welding, and injection molding, which allows us to provide our customers with ONE-STOP-SOLUTION. These comprehensive capabilities allow us to produce top-notch products that meet the highest standards of quality.

At Honsen Magnetics, we take great pride in our customer-centric approach. Our philosophy revolves around putting the needs and satisfaction of our clients above everything else. This commitment ensures that we not only deliver exceptional products but also provide excellent service throughout the entire customer journey.

Moreover, our exceptional reputation extends beyond borders. By consistently offering reasonable prices and maintaining superior product quality, we have gained immense popularity in Europe, America, Southeast Asia, and other countries. The positive feedback and trust we receive from our customers further solidify our standing in the industry.

Honsen Magnetics stands as a reliable and renowned supplier in the field of Permanent Magnets and Magnetic Assemblies. With our extensive experience, state-of-the-art manufacturing processes, skilled workforce, and unwavering commitment to customer satisfaction, we continue to thrive and make a significant impact in the global market.

OUR ADVANTAGES

- More than 10 years experience in permanent magnetic products industry

- Over 5000m2 factory is equipped with 200 advanced Machines

- Have a complete production line from machining, assembling, welding, injection molding

- With 2 production plants, 3000 tons/year for magnets and 4m units/month for magnetic products

- Having strong R&D team can provide perfect OEM&ODM service

- Have the certificate of ISO 9001, IATF 16949, ISO14001, ISO45001, REACH, and RoHs

- Strategic cooperation with the top 3 rare blank factories for raw materials

- High rate of automation in Production & Inspection

- 0 PPM for Magnets & Magnetic Assemblies

- FEA simulation to calculate and optimize magnetic circuits

- Skilled workers & continuous improvement

- We only export qualified products to customers

- We enjoy a hot market in most parts of Europe, America, Asia & others

- Fast shipping & worldwide delivery

- Offer free magnetic solutions

- Bulk discounts for larger orders

- Serve ONE-STOP-SOLUTION ensure efficient & cost-effective purchasing

- 24-hour online service with first-time response

- Work with big customers & small ones without MOQ

- Offer all kinds of payment methods

PRODUCTION FACILITIES

Since our establishment, prioritizing the quality of our products has always been our topmost concern. We strive relentlessly to enhance both our products and production processes, assuring you that you will receive the requested products of the utmost quality. This is not merely a claim but a commitment we uphold on a daily basis. Our team comprises experienced professionals who excel at every stage of production.

To ensure product and process excellence, we employ Advanced Product Quality Planning (APQP) and Statistical Process Control (SPC) systems, which diligently monitor and manage conditions during pivotal manufacturing stages. Rest assured, our dedication to delivering exceptional products remains unwavering. By continuously striving for improvement and implementing stringent quality control measures, we stand by our promise of providing you with the finest products available.

With our proficient workforce and robust quality management systems, we are confident in our ability to consistently meet and exceed your expectations. Your satisfaction with our high-quality offerings is our ultimate goal.

QUALITY & SAFETY

Quality management lies at the core of our organization, forming the foundation on which we thrive. At Honsen Magnetics we firmly believe that quality is not merely a theoretical construct; it is the driving force behind every decision and action we take.

Our unwavering commitment to excellence manifests in all aspects of our operations. We have adopted a comprehensive approach to quality management, seamlessly incorporating it into every facet of our organization. This holistic integration ensures that quality is not an afterthought but an inherent aspect of our processes and products. From raw materials procurement to production and customer service, our quality management system permeates every stage. Our paramount goal is to consistently surpass the expectations of our customers. By adhering to stringent quality control measures and leveraging cutting-edge technology, we meticulously craft products of unrivaled excellence. Our dedication to exceeding customer expectations is not a mere statement but woven into the fabric of our organization.

Our success hinges on our unwavering dedication to quality management. By integrating it seamlessly into our operations, we consistently deliver exceptional products that reflect our steadfast commitment to excellence.

PACKING & DELIVERY

TEAM & CUSTOMERS

At Honsen Magnetics, we believe that the key to our success lies in our ability to satisfy our customers and maintain excellent safety practices. However, our commitment to perfection doesn't stop there. We also prioritize the personal development of our workforce.

By creating a nurturing environment, we encourage our employees to grow both professionally and personally. We provide them with opportunities for training, skill enhancement, and career advancement.

We empower our workforce to reach their full potential. We recognize that investing in personal growth is vital for long-term success. As individuals within our organization develop their skills and knowledge, they become more valuable assets, contributing to the overall strength and competitiveness of our business.

By promoting personal development within our workforce, we not only lay the foundation for our own enduring success but also foster a culture of continuous improvement. Our commitment to satisfying customers and ensuring safety is complemented by our dedication to the growth and development of our employees. These pillars form the cornerstone of our business.

CUSTOMERS' FEEDBACK