Custom Magnets

We offer custom solutions tailored to meet the unique needs of our customers. Our team can work with you to design and produce neodymium magnets in a range of shapes, sizes, and strengths, with custom coatings to suit your specific requirements. We use high-quality materials and advanced manufacturing processes to ensure that our magnets are of the highest quality. Whether you need magnets for use in high-temperature environments, corrosive settings, or other specialized applications, our neodymium magnets can be customized.-

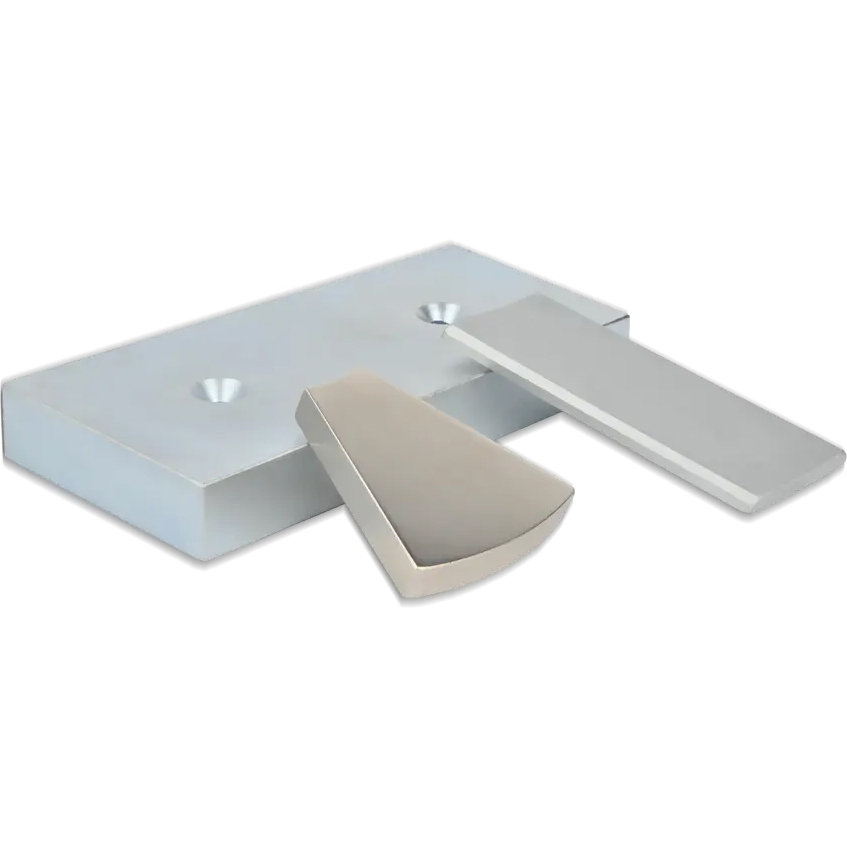

Countersunk Magnets

Product Name: Neodymium Magnet with Countersunk/Countersink Hole

Material: Rare Earth Magnets/NdFeB/ Neodymium Iron Boron

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: Customized -

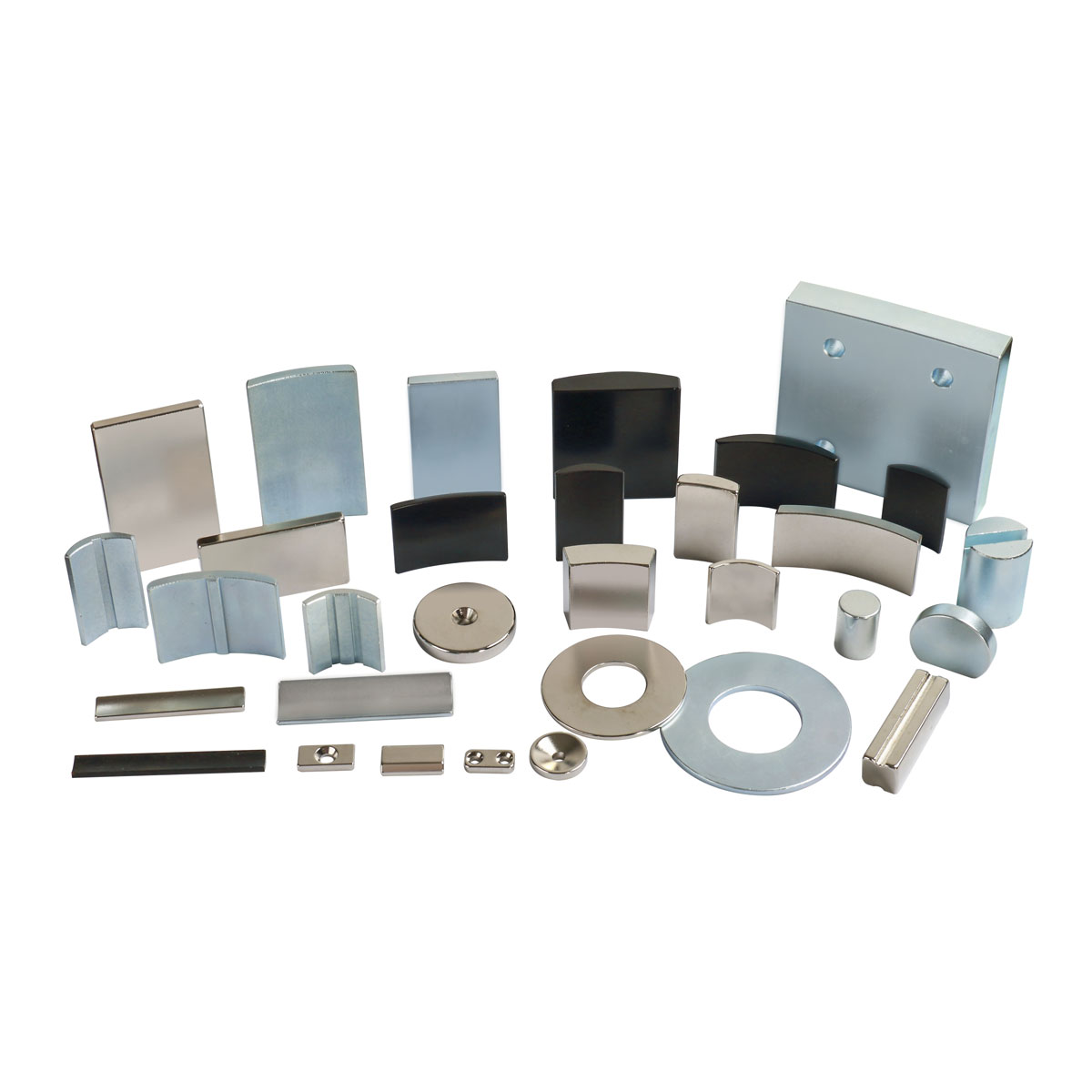

Custom Neodymium Iron Boron Magnets

Product Name: NdFeB Customized Magnet

Material: Neodymium Magnets / Rare Earth Magnets

Dimension: Standard or customized

Coating: Silver, Gold, Zinc, Nickel, Ni-Cu-Ni. Copper etc.

Shape: As per your request

Lead time: 7-15 days

-

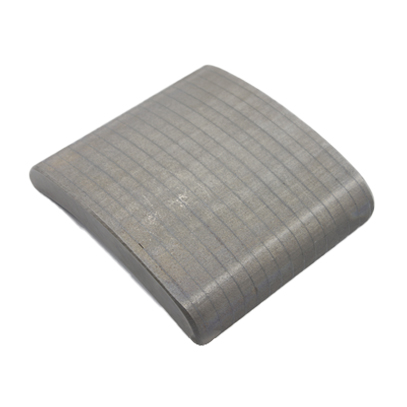

Laminated Permanent Magnets to reduce Eddy Current Loss

The purpose to cut a whole magnet into several pieces and apply the together is to reduce eddy loss. We call this kind magnets “Lamination”. Generally, the more pieces, the better the effect of eddy loss reduction. The lamination will not deteriorate the overall magnet performance, only the flux will slightly affected. Normally we control the glue gaps within a certain thickness using special method to control each gap has the same thickness.

-

Permanent Magnets used in Automotive Industry

There are many different uses for permanent magnets in automotive applications, including efficiency. The automotive industry is focused on two kinds of efficiency: fuel-efficiency and efficiency on the production line. Magnets help with both.

-

Neodymium Magnets for Household Appliances

Magnets are widely used for speakers in TV sets, magnetic suction strips on refrigerator doors, high-end variable frequency compressor motors, air conditioning compressor motors, fan motors, computer hard disk drives, audio speakers, headphone speakers, range hood motors, washing machine motors, etc.

-

Elevator Traction Machine Magnets

Neodymium Iron Boron magnet, as the latest result of the development of rare earth permanent magnetic materials, is called “magneto king” because of its excellent magnetic properties. NdFeB magnets are alloys of neodymium and iron oxide. Also known as Neo Magnet. NdFeB has extremely high magnetic energy product and coercivity. At the same time, the advantages of high energy density makes NdFeB permanent magnets widely used in modern industry and electronic technology, which makes it possible to miniaturize, lightweight and thin instruments, electroacoustic motors, magnetic separation magnetization and other equipment.

-

Super Strong Neo Disc Magnets

Disc Magnets are the most common shaped magnets used in today’s major market for its economic cost and versatility. They are used in numerous industrial, technical, commercial and consumer applications due to their high magnetic strength in compact shapes and round, wide, flat surfaces with large magnetic pole areas. You’ll get an economic solutions from Honsen Magnetics for you project, contact us for details.

-

Coatings & Platings Options of Permanent Magnets

Surface Treatment: Cr3+Zn, Color Zinc, NiCuNi, Black Nickel, Aluminium, Black Epoxy, NiCu+Epoxy, Aluminium+Epoxy, Phosphating, Passivation, Au, AG etc.

Coating Thickness: 5-40μm

Working Temperature: ≤250 ℃

PCT: ≥96-480h

SST: ≥12-720h

Please contact our expert for coating options!