Neodymium Magnets also know as Neo, NdFeB magnets, Neodymium Iron Boron or Sintered Neodymium, are the strongest commercially available rare earth permanent magnets. These magnets offer the highest energy product and available to be manufactured in a wide range of shape, sizes and grades including GBD. The magnets can be plated with different coating to protect from corrosion. Neo magnets can be found in a variety of applications including high performance motors, brushless DC motors, magnetic separation, magnetic resonance imaging, sensors and loudspeakers.

We custom manufacture magnets to a broad range of shapes and configurations, and with special features to meet your application and performance requirements including:

-Rectangles, arcs, discs, rings, or complex shapes.

-Magnetic orientation to your specified angle.

-Special coatings

-Different grades (N/M/H/UH/EH/AH, rating from 80℃ to 230℃)

-Data as required (dimensional & magnetic inspection, material traceability)

| Surface Treatment | ||||||

| Coating | Coating Thickness (μm) |

Color | Working Temperature (℃) |

PCT (h) | SST (h) | Features |

| Blue-White Zinc | 5-20 | Blue-White | ≤160 | - | ≥48 | Anodic coating |

| Color Zinc | 5-20 | Rainbow color | ≤160 | - | ≥72 | Anodic coating |

| Ni | 10-20 | Silver | ≤390 | ≥96 | ≥12 | High temperature resistance |

| Ni+Cu+Ni | 10-30 | Silver | ≤390 | ≥96 | ≥48 | High temperature resistance |

| Vacuum aluminizing |

5-25 | Silver | ≤390 | ≥96 | ≥96 | Good combination, high temperature resistance |

| Electrophoretic epoxy |

15-25 | Black | ≤200 | - | ≥360 | Insulation, good consistency of thickness |

| Ni+Cu+Epoxy | 20-40 | Black | ≤200 | ≥480 | ≥720 | Insulation, good consistency of thickness |

| Aluminium+Epoxy | 20-40 | Black | ≤200 | ≥480 | ≥504 | Insulation, strong resistance to salt spray |

| Epoxy spray | 10-30 | Black, Grey | ≤200 | ≥192 | ≥504 | Insulation, high temperature resistance |

| Phosphating | - | - | ≤250 | - | ≥0.5 | Low cost |

| Passivation | - | - | ≤250 | - | ≥0.5 | Low cost, invironment friendly |

| Contact our experts for other coatings! | ||||||

Neo magnets have some limitations due to their corrosive behavior. In humid applications, a protective coating is highly recommended. Coatings which have been used successfully include epoxy coating, nickel plating, Zinc coating and combinations of these coatings. We also has the capability to apply Parylene or everlube coating to neodymium magnets. Effectiveness of coating is dependent upon the quality of the base material. Choose the right plating for your products!

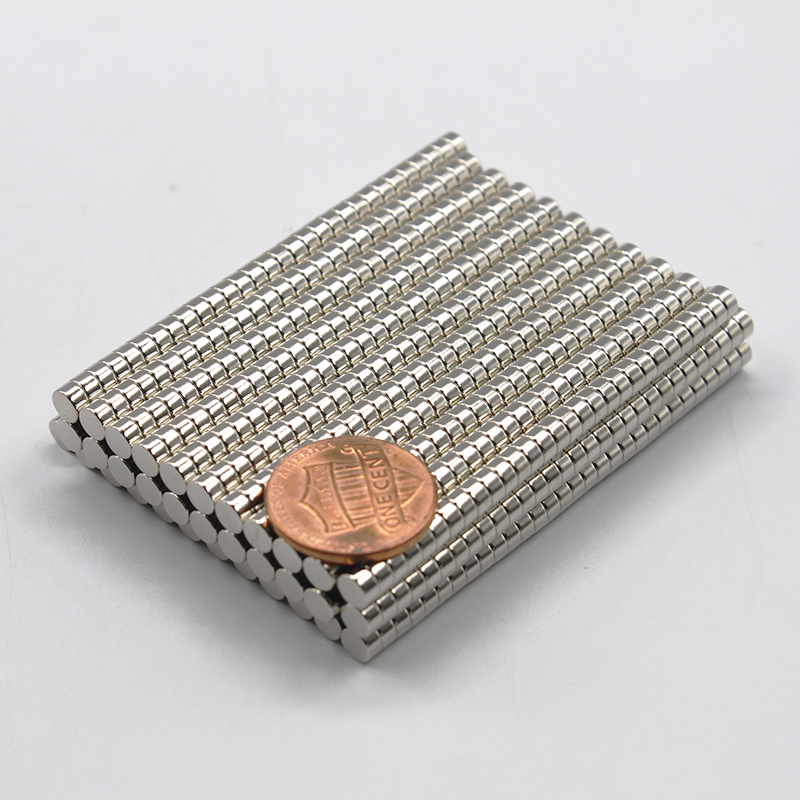

Neodymium rod and cylinder magnets are useful for multiple applications. From crafting & metal working applications to exhibition displays, audio equipment, sensors, motors, generators, medical instruments, magnetically coupled pumps, hard disk drives, OEM equipment and much more.

-Spindle and Stepper Motors

-Drive Motors in Hybrid and Electric Vehicles

-Electric Wind Turbine Generators

-Magnetic Resonance Imaging (MRI)

-Electronic Medical Devices

-Magnetic Bearings