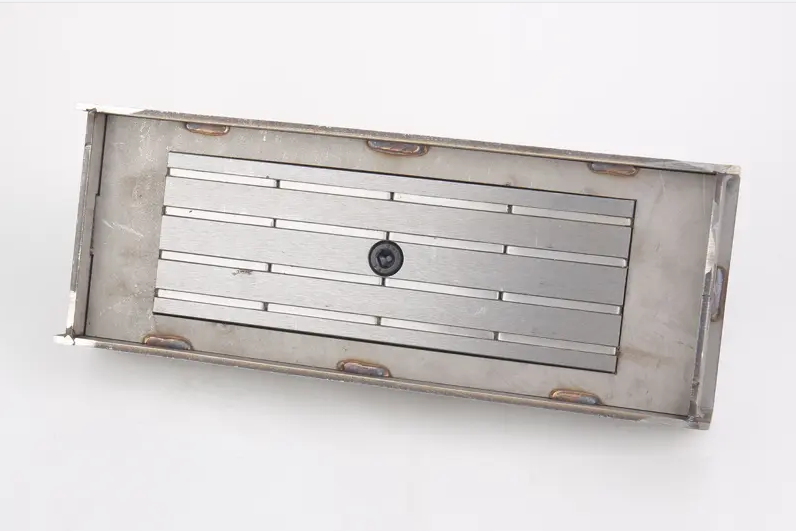

Formwork Magnets are essential and valuable accessories in all precast concrete systems. These magnets are manufactured using high-performance NdFeB Magnet materials, making them top-of-the-line products. To ensure convenient usage, this precast concrete magnet is equipped with spring screw connection fittings. Additionally, its button and housing components are constructed from Carbon Steel or Stainless Steel 304, ensuring durability and longevity.

Honsen Magnetics has perfected the craftsmanship of stencil magnets. Continue reading to gain comprehensive insights into their applications, maintenance, and their transformative impact on the precast concrete industry. At Honsen Magnetics, our team of dedicated in-house engineers has designed state-of-the-art magnet configurations. Prefabricated concrete magnets possess an incredible magnetic field strength and attractive force, exceeding 200 times their own weight. The interaction between magnetically permeable materials coordinates the changes in the alignment of field lines within each magnet.

When we embarked on the production of formwork magnets, we aimed for limitless possibilities. At Honsen Magnetics, our team of talented magnetic experts is dedicated to manufacturing these intricate magnet configurations. Prefabricated concrete magnets boast exceptional magnetic field strength and attractive force, surpassing 200 times their own weight. The interplay of magnetically permeable materials results in a reconfiguration of the field lines specific to each magnet.

During application, the precast concrete magnet securely attaches to the steel mold platform through its base. This fusion of magnet and platform forms a comprehensive magnetic circuit closure system, exhibiting remarkably powerful holding forces. Stencil magnets maintain their stability, preventing any movement, sliding, or shifting, thereby enhancing safety and user-friendliness.

The template magnet is composed of a switchable NdFeB template magnet unit, a magnet block housed within a casing, and fixing screws. By combining neodymium magnets with steel plates, we create a robust magnetic circuit that generates a powerful attraction force. This force effectively secures the wood or steel formwork in place. The control buttons are conveniently located on the top of the precast concrete magnets. When the button is pressed, the magnet activates its magnetic circuit, firmly holding the template onto the steel plate. Conversely, the deactivation button allows for easy repositioning of the magnet. The template magnet features two universally threaded holes on the top, designed to accommodate various adapters. Our products can be customized according to your specific requirements, offering a diverse range of applications.

At the apex of the shuttering magnets, there exists a toggle switch. In an operational state, by pressing this button, the magnet box securely affixes the shuttering onto the platform. Engaging the lever to lift the button places the magnet box in a closed state, rendering it movable.

- The adhesive strength of the magnet box relies on the platform's thickness and smoothness. Thicker and smoother surfaces yield superior results. Additionally, the lateral shear force hinges on both the magnet box's adhesion and the friction coefficient of the contact area.

- On either side of the magnet box, two screws are present, allowing for connection with various adapters. This feature facilitates the attachment of diverse formworks, including steel angles, steel channels, and more.

- Honsen Magnetics' shuttering magnet is constructed using permanent neodymium magnets. In principle, if the maximum operating temperature remains below 80°C and the magnet sustains no damage or corrosion, the adhesive force will endure indefinitely.

- Installation is straightforward and operation is user-friendly.

- Offers the flexibility to choose desired fixed positions, reducing installation time.

- Cost-effective, with a fast return on investment.

- Durable design ensures a longer lifespan, allowing for reusability.

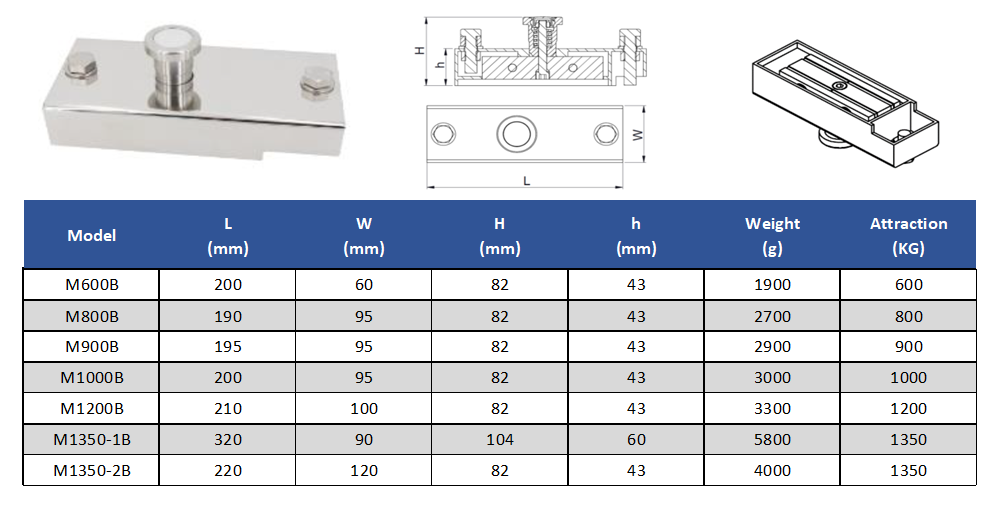

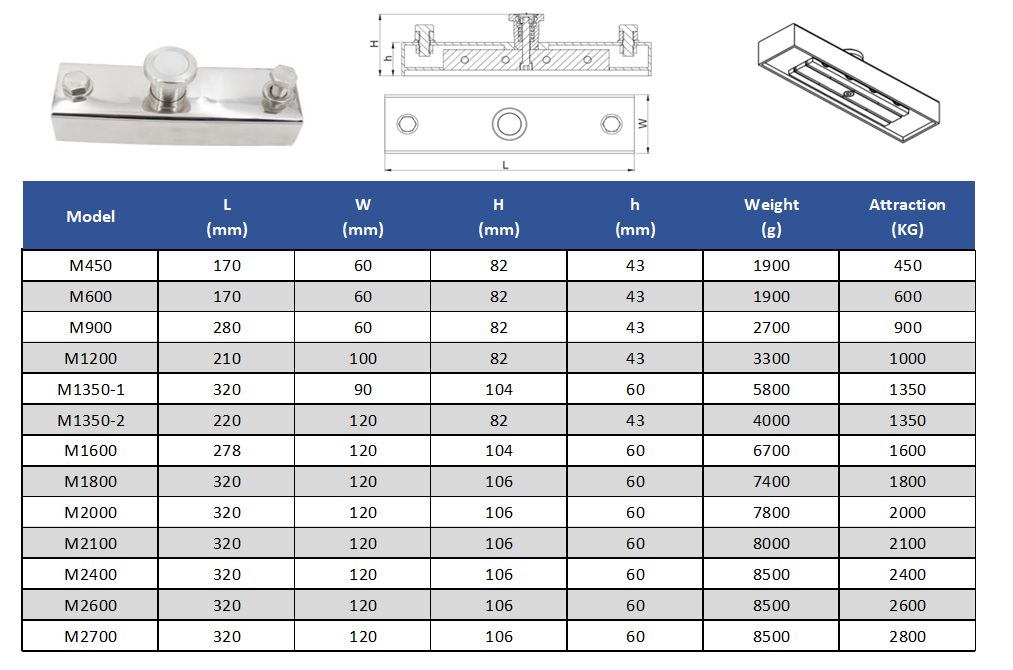

- Adhesive force ranges from 450 KGS to 3100 KGS, providing strong holding power.

- Eliminates the need for welding; the magnet's magnetic force securely holds the template in position.

- Highly versatile, a single precast formwork magnet can be used with various types of concrete formworks.

Why should you use Shuttering Magnets?

Shuttering Magnets for Formwork have revolutionized the precast concrete industry, leading to remarkable advancements! Take a look at the following advantages of utilizing them. While we've listed the reasons why, it's safe to say that the benefits of closing a magnet are nearly limitless.

- Unmatched convenience with a 70% faster workflow compared to traditional methods.

- Safeguard your die tables from the detrimental effects of drilling, without the need for welding, ensuring an extended lifespan.

- Reduce labor costs significantly with the use of shutter magnets, enabling a rapid payback cycle.

- Remarkable versatility and adaptability to diverse formwork materials like plastic, steel, and wood.Infinite application possibilities with the option to customize magnets to cater to your specific requirements.

- Eliminate the need for multiple specialized tools, as these magnets possess remarkable strength to elevate board height and anchor it securely to the steel workbench.

- Specifically designed for reliable use in concrete plants, ensuring steadfast side contact.

- A cost-effective solution for constructing components.

- User-friendly design allows for easy disassembly and assembly.

- Promotes the reusability of formwork molds, resulting in long-term cost savings.

- Applicable for a wide range of manufacturing scenarios, including both individual and large-scale production of concrete products on steel tables.

- Drastically reduces the time required for formwork installation.

- Customizable template magnets to cater to diverse requirements.

- Effortless operation with precise magnet positioning.

- Versatile in compatibility, suitable for both wood and steel formwork.

- Boasts a strong bonding capacity to withstand loads ranging from 450 KGS to 3100 KGS.

- Safeguards formwork tables without the need for surface drilling, welding, or bolting.

- Preserves the integrity of the surface, leading to a longer lifespan.

- Offers multifunctionality with a single magnet serving various purposes.

- Adjustable built-in threaded holes to accommodate different formwork dimensions.

- Enhances the productivity and quality of precast concrete walls.

Honsen Magnetics has been at the forefront of manufacturing and supplying permanent magnets, magnetic components, and magnetic articles for over a decade. Our skilled team manages a full range of production activities from machining and assembly to welding and injection molding. We enjoy a great reputation in Europe and America, and our success is attributed to our competitively priced quality products, as well as our strong commitment to customer-centric service.

- More than 10 years experience in permanent magnetic products industry

- Over 5000m2 factory is equipped with 200 advanced Machines

- Have a complete production line from machining, assembling, welding, injection molding

- Have a strong R&D team can provide perfect OEM&ODM service

- Skilled workers & continuous improvement

- We only export qualified products to customers -

- Fast shipping & worldwide delivery

- Serve ONE-STOP-SOLUTION ensure efficient & cost-effective purchasing

- 24-hour online service with first-time response

Our main goal is to provide our customers with forward-looking support and revolutionary, competitive products, ultimately enhancing our market position. Through our commitment to technological innovation, we aggressively pursue growth and explore new avenues to market through unique breakthroughs in permanent magnets and components. Led by our chief engineer, our experienced R&D department leverages in-house expertise, cultivates strong customer relationships, and anticipates market trends. Independent teams oversee global projects, ensuring that research continues to progress.

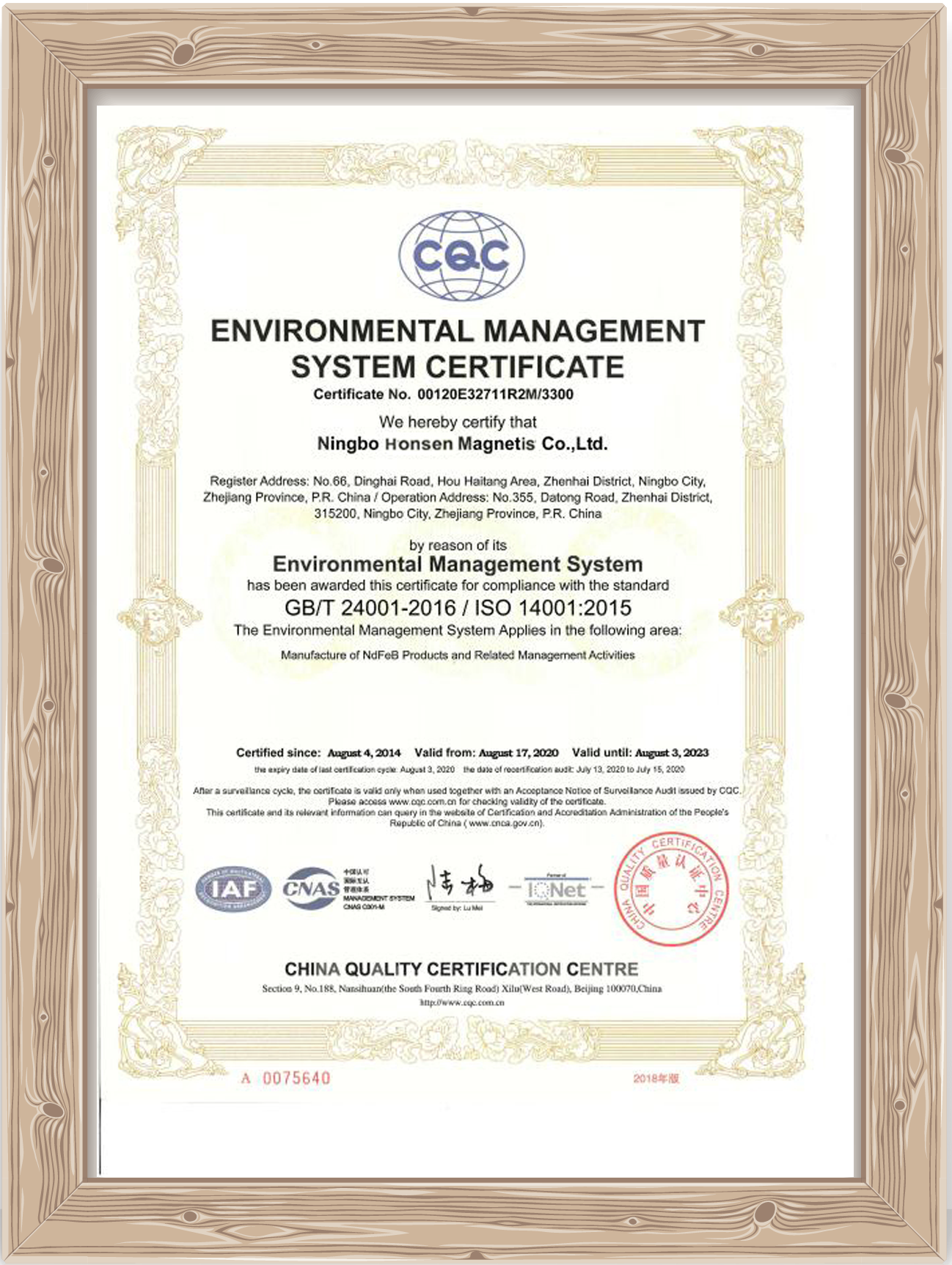

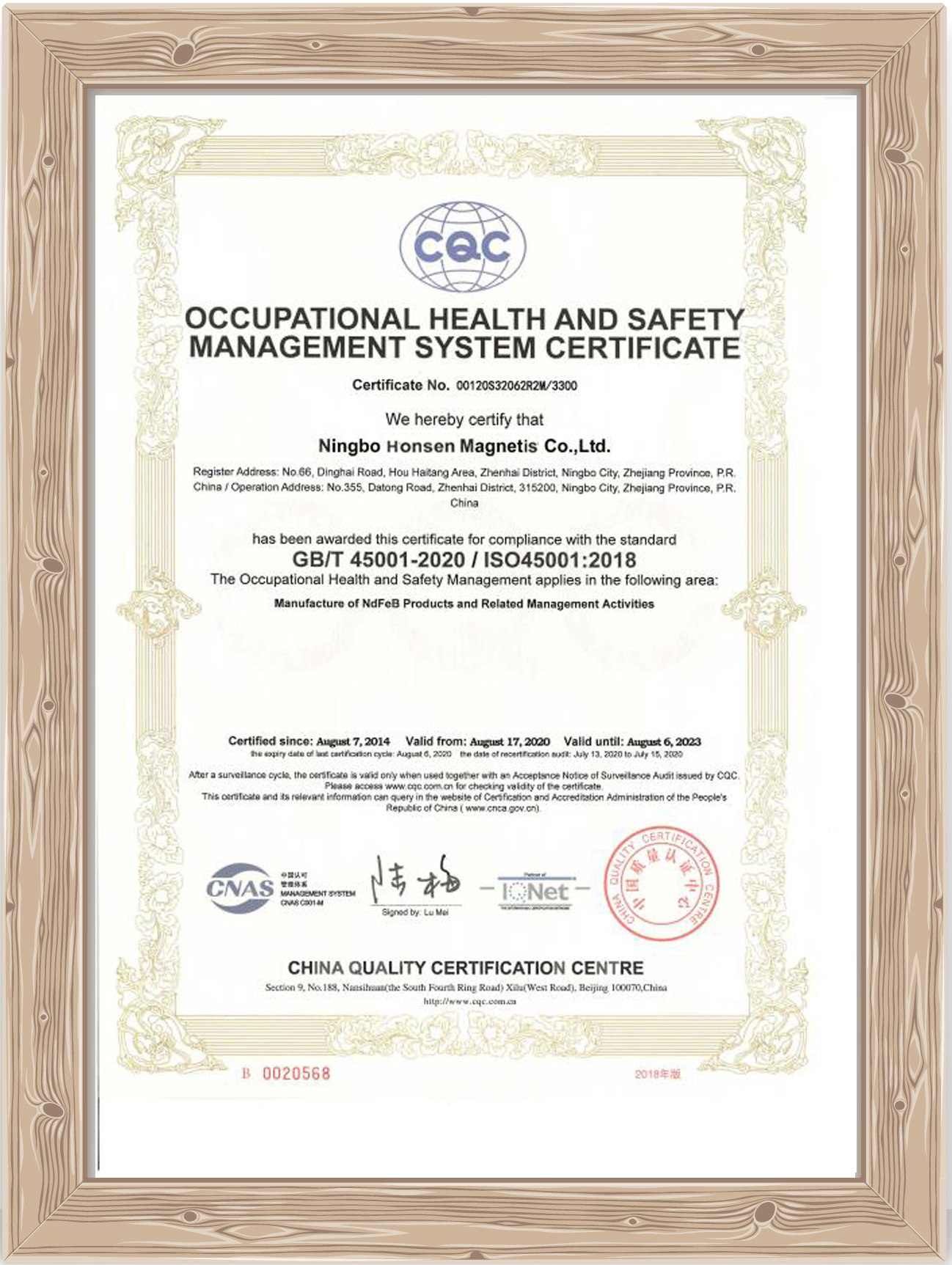

Quality management is deeply rooted in our corporate culture. We regard quality as the essence and guiding force of the enterprise. Our commitment is unwavering - we seamlessly integrate our quality management system into our operations. This ensures that our products always meet and exceed customer expectations, underscoring our uncompromising commitment to quality.

Honsen Magnetics is synonymous with excellence, rooted in prioritizing customer satisfaction and safety. Our commitment to the holistic development of our people complements this philosophy. By nurturing the journey of each employee, we lay the foundation for continuous, long-term business growth.